Sep . 01, 2025 04:20 Back to list

Blue Coated Glass: Premium Solar Control & Aesthetics

Introduction to Coated Glass Technology

In the advanced materials sector, blue coated glass represents a critical innovation, offering superior performance characteristics across diverse industrial and architectural applications. This specialized glass is engineered through advanced deposition techniques to impart specific functional properties, such as enhanced solar control, thermal insulation, and aesthetic appeal. Unlike standard float glass, coated variants significantly improve energy efficiency and occupant comfort, addressing the growing demand for sustainable building materials and high-performance industrial components. Understanding its technical intricacies, application versatility, and manufacturing precision is paramount for B2B decision-makers and engineers seeking optimal material solutions.

The application range of blue coated glass is extensive, covering everything from facades of modern skyscrapers to specialized industrial glazing. Its development is driven by ongoing research in material science and optics, continuously pushing the boundaries of what glass can achieve in terms of durability, optical clarity, and energy management. This article delves into the core aspects of this technology, exploring its manufacturing process, technical specifications, diverse application scenarios, and the strategic advantages it offers in today’s competitive market.

Current Industry Trends in Coated Glass

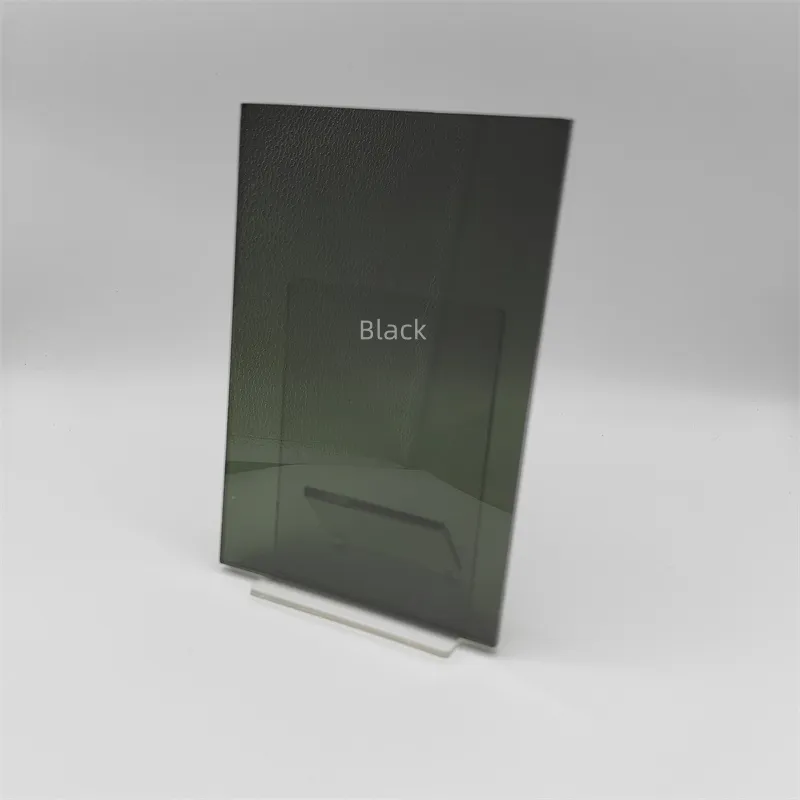

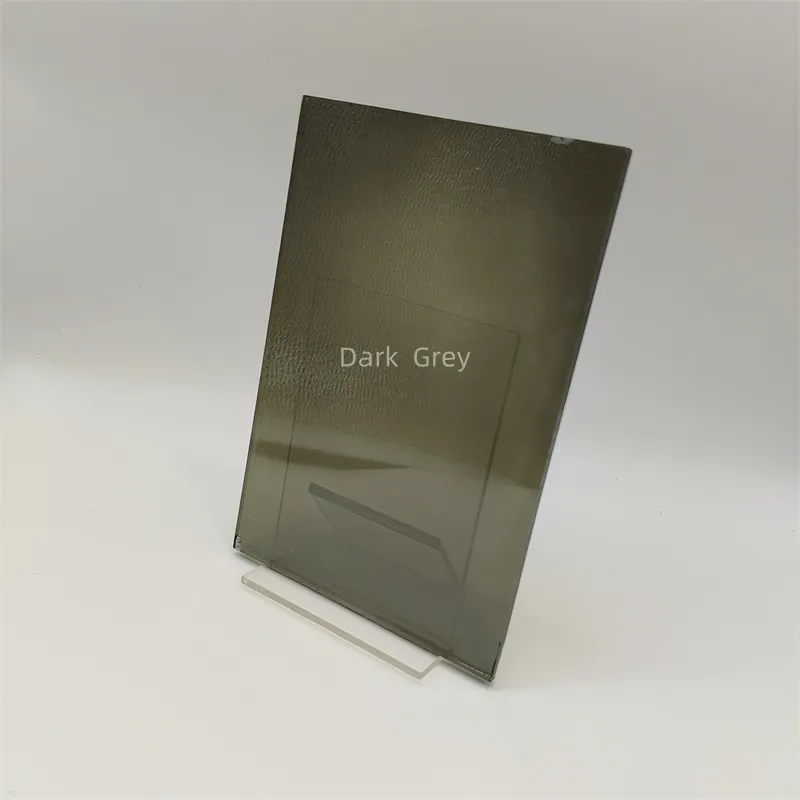

The global coated glass market is experiencing robust growth, primarily propelled by stringent energy efficiency regulations, increasing demand for sustainable building materials, and the rapid expansion of smart city initiatives. Key trends include the proliferation of low-emissivity (Low-E) coatings for enhanced thermal insulation, the integration of switchable electrochromic technologies, and the development of self-cleaning and anti-reflective coatings. The market for aesthetic coatings, such as blue coated glass and black coated glass, is also expanding, driven by architectural design preferences that seek both functionality and visual impact.

Data from recent industry analyses indicate a compound annual growth rate (CAGR) of over 7% for the global coated glass market, projected to reach USD 45 billion by 2028. This growth is significantly influenced by technological advancements in coating application methods, such as magnetron sputtering and pyrolytic deposition, which allow for more durable and spectrally selective layers. Furthermore, the increasing adoption of double and triple-glazed insulated glass units (IGUs) incorporating coated glass layers is a major contributor to market expansion, particularly in regions with diverse climatic conditions.

Detailed Manufacturing Process Flow of Blue Coated Glass

The production of blue coated glass is a sophisticated, multi-stage process that combines precision engineering with advanced material science. It begins with high-quality float glass, which serves as the substrate. The choice of substrate material is critical, often a low-iron clear float glass to ensure optimal optical transparency and color neutrality before coating.

Process Steps:

- Substrate Preparation: High-quality float glass sheets are meticulously cleaned using a multi-stage washing process involving deionized water, specialized detergents, and high-pressure brushes. This removes all surface contaminants, ensuring pristine adhesion for subsequent layers. Surface tension analysis verifies cleanliness.

- Coating Deposition (Magnetron Sputtering): This is the primary method for applying the desired optical and functional layers. In a vacuum chamber, the clean glass is passed beneath a series of magnetron cathodes. These cathodes contain target materials, typically metals (e.g., silver, titanium, chromium) or metal oxides (e.g., silicon dioxide, tin oxide), which are bombarded by argon ions. This bombardment dislodges atoms from the target, which then travel and deposit onto the glass surface, forming extremely thin, uniform layers (nanometer scale). For a blue tint and specific solar control properties, layers might include a combination of dielectric films and thin metallic layers designed to selectively reflect or absorb certain wavelengths of light.

-

Layer Configuration: Multiple layers are applied sequentially. A typical coating stack for blue coated glass might include:

- Protective layer (e.g., TiO2, SiO2)

- Functional layer (e.g., Ag for Low-E properties, or specific metal alloys for color)

- Barrier layer (e.g., NiCr)

- Another functional layer (for enhanced performance or specific blue coloration)

- Top protective layer

-

Quality Control & Testing: Throughout the process, and post-coating, rigorous testing is conducted. This includes:

- Optical Spectrophotometry: Measures visible light transmittance, reflectance, solar heat gain coefficient (SHGC), and U-value (thermal transmittance) to ensure compliance with specified performance parameters.

- Adhesion Testing: Cross-hatch adhesion tests and scrub resistance tests verify coating durability.

- Environmental Durability: Accelerated weathering tests (humidity, salt spray, UV exposure) are performed to predict service life, often adhering to ISO 9227 (Salt Spray) and ASTM C1376 (Standard Test Method for Measurement of Architectural Glass by Spectrophotometry).

- Visual Inspection: Ensures freedom from defects such as pinholes, scratches, or uneven coating.

- Cutting & Finishing: The coated glass is then cut to precise dimensions using CNC machining, followed by edge processing (e.g., grinding, polishing) and tempering (if required for safety glass applications) to meet specific project requirements.

Materials, Standards, and Service Life:

Typical materials used in coating include silver (Ag) for low-emissivity, titanium (Ti), silicon dioxide (SiO2), tin oxide (SnO2), and various nitrides for durability and specific optical properties. Our products conform to international standards such as ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and specific product performance standards like EN 1096 (Coated Glass for Buildings) and ANSI Z97.1 (Safety Glazing Materials). With proper installation and maintenance, the service life of high-quality blue coated glass can exceed 20-30 years in typical architectural applications, demonstrating excellent resistance to delamination and environmental degradation.

Target Industries & Advantages:

Target industries include architecture and construction (commercial and residential facades, curtain walls), automotive (windshields, panoramic roofs), and specialized industrial applications (refrigeration, display cases). In energy-saving scenarios, such as high-rise buildings, blue coated glass significantly reduces HVAC load by managing solar heat gain, leading to substantial operational cost reductions. For environments requiring corrosion resistance, such as certain petrochemical or coastal facilities, advanced coatings can offer enhanced durability against atmospheric pollutants and saline conditions, extending the lifespan of the glazing system.

Technical Specifications and Performance Parameters

The performance of coated glass is quantified by several critical parameters that define its energy efficiency, optical properties, and durability. These specifications are crucial for architects, engineers, and procurement specialists to ensure the chosen glass meets project requirements and environmental regulations.

Representative Specifications for Blue Coated Glass (6mm single pane)

| Parameter | Metric | Value Range | Description / Standard |

|---|---|---|---|

| Visible Light Transmittance (VLT) | % | 15% - 40% | Amount of visible light passing through. (EN 410) |

| External Visible Light Reflectance (VLR-e) | % | 18% - 35% | Amount of visible light reflected outwards. (EN 410) |

| Solar Heat Gain Coefficient (SHGC / g-value) | Unitless | 0.20 - 0.45 | Fraction of solar radiation admitted. Lower is better for cooling. (NFRC 200, EN 410) |

| U-value (Thermal Transmittance) | W/(m²·K) | 2.5 - 3.5 (single) | Rate of heat loss/gain. Lower is better. (EN 673) |

| Shading Coefficient (SC) | Unitless | 0.23 - 0.52 | Ratio of solar heat gain relative to 3mm clear glass. |

| Emissivity (ε) | Unitless | 0.03 - 0.20 | Ability of surface to radiate heat. Lower is better. (ASTM E408) |

| Chemical Durability | Grade | A1 (Highest) | Resistance to acids/alkalis. (EN 1096-2) |

These parameters demonstrate how blue coated glass is engineered for optimal thermal and optical performance. For instance, a low SHGC value is ideal for reducing cooling loads in hot climates, while a low U-value is crucial for minimizing heat loss in colder environments. The distinctive blue hue is achieved by precisely controlling the interference effects of the thin-film layers.

Application Scenarios and Coated Glass Uses

The versatility of blue coated glass makes it suitable for a wide array of applications where aesthetics, energy efficiency, and functional performance are paramount. Understanding these diverse coated glass uses is key for project specification.

- Commercial Building Facades: High-rise office buildings, hotels, and retail complexes frequently employ blue coated glass for their exterior glazing. The coating's ability to manage solar heat gain significantly reduces air conditioning costs, while its reflective properties provide privacy and a distinct architectural aesthetic. The uniform blue tint contributes to a modern and sophisticated appearance.

- Residential Architecture (High-End): Luxury homes and condominiums utilize blue coated glass for large windows and sliding doors, where energy efficiency and visual appeal are highly valued. It enhances indoor comfort by maintaining stable temperatures and reducing glare, contributing to a premium living experience.

- Industrial Facilities (Process Control Rooms, Skylights): In industries such as petrochemicals, metallurgy, and water treatment, where internal environments need to be protected from external elements and energy costs are significant, blue coated glass offers robust solutions. It can be integrated into specialized insulated glass units (IGUs) for process control rooms, providing clear views while minimizing heat transfer and protecting against UV radiation. For skylights, it helps to control daylighting and prevent overheating.

- Transportation Sector: While less common than in buildings, specialized coated glass is used in panoramic train windows, yacht glazing, and certain automotive applications (e.g., roof panels) where controlled light transmission and solar reflection are beneficial for passenger comfort and interior cooling.

- Refrigeration and Display Units: In commercial refrigeration, specialized coated glass (often Low-E) prevents condensation and improves insulation. Blue tinting can be used for aesthetic differentiation in high-end display cases.

Beyond its primary function in solar control and thermal insulation, the aesthetic appeal of blue coated glass—and other variants like black coated glass—offers designers flexibility in achieving unique architectural expressions, contributing to the overall visual identity of a structure.

Technical Advantages and Economic Value

The adoption of blue coated glass provides a multitude of technical and economic advantages for construction projects and industrial applications. These benefits extend beyond mere aesthetics, delivering tangible value in terms of energy savings, occupant comfort, and structural longevity.

Key Advantages:

- Superior Energy Efficiency: By significantly reducing solar heat gain (low SHGC) and minimizing heat transfer (low U-value), blue coated glass drastically lowers heating, ventilation, and air conditioning (HVAC) loads. This translates directly into substantial energy cost savings over the building's lifecycle.

- Enhanced Occupant Comfort: The controlled transmission of sunlight reduces glare, creating a more comfortable indoor environment. By mitigating heat ingress, it helps maintain stable internal temperatures, reducing "hot spots" near windows.

- UV Protection: The coatings effectively block a significant percentage of harmful UV radiation, protecting interior furnishings, artwork, and occupants from fading and damage. This extends the lifespan of interior assets.

- Aesthetic Versatility: The distinctive blue hue offers architects and designers a powerful tool for achieving specific visual effects and brand identity. This aesthetic control is a significant differentiator.

- Durability and Low Maintenance: Modern coating technologies are highly durable, resistant to scratches and environmental degradation. Many coatings are on the second or third surface of an IGU, protecting them further. With its robust properties, it offers a long service life with minimal maintenance requirements.

- Sustainability Credentials: By reducing energy consumption, buildings equipped with coated glass contribute to lower carbon footprints, helping projects achieve green building certifications like LEED and BREEAM.

Vendor Comparison: Evaluating Coated Glass Suppliers

Choosing the right supplier for blue coated glass is crucial for ensuring project success, quality, and long-term performance. A comprehensive evaluation involves assessing not just the product's coated glass price, but also technical capabilities, certifications, and service reliability.

Comparative Analysis of Leading Coated Glass Vendors

| Feature/Criterion | Vendor A (Specialist) | Vendor B (Large Manufacturer) | Vendor C (Regional Provider) |

|---|---|---|---|

| Product Range (Blue Coated) | Extensive blue tints, custom optical specs | Standard blue series, high volume | Limited blue options, focus on common VLT/SHGC |

| Certifications (ISO, EN, NFRC) | ISO 9001, EN 1096-2, NFRC certified, CE | ISO 9001, EN 1096-1, CE | ISO 9001 (basic), Local standards |

| Customization Capabilities | High (custom colors, specific performance, R&D) | Moderate (sizing, basic laminations) | Low (standard dimensions) |

| Lead Time (Typical) | 4-6 weeks (complex custom) | 2-4 weeks (standard stock) | 1-3 weeks (small orders) |

| Technical Support | Dedicated engineering team, project consultancy | Standard sales & technical docs | Basic customer service |

| Warranty Period | 10-15 years (performance & coating) | 5-10 years (coating) | 2-5 years (basic) |

This comparison highlights the trade-offs between specialized capabilities, volume production, and regional accessibility. For complex projects requiring unique optical properties or specific aesthetic matches, a specialist vendor offers greater flexibility and expertise. For standard applications, larger manufacturers often provide more competitive coated glass price points and faster lead times for common specifications.

Customized Solutions for Blue Coated Glass

While standard blue coated glass products meet many requirements, complex architectural and industrial projects often necessitate tailored solutions. Our capabilities extend to comprehensive customization to align with unique aesthetic, performance, and structural demands.

- Tailored Optical Performance: We can engineer specific VLT, SHGC, and U-value targets by adjusting the multi-layer coating stack. This allows for fine-tuning energy performance for specific climate zones or building orientations.

- Custom Color Matching: Beyond standard blue, we can develop proprietary coating formulations to achieve precise color matches for branding or unique architectural visions. This includes varying levels of reflectivity and subtle shifts in hue.

- Integrated Functionalities: Customization includes combining blue coatings with additional features such as anti-reflective layers, self-cleaning (hydrophilic or hydrophobic) treatments, anti-condensation properties, or enhanced acoustic insulation through lamination.

- Size and Shape: We accommodate oversized glass panels and complex geometries, including curved glass, requiring specialized cutting (CNC machining) and coating processes.

- Substrate Options: Custom solutions may involve different glass substrates, such as low-iron glass for maximum clarity, heat-strengthened, fully tempered, or laminated glass for enhanced safety and security.

Our R&D team works closely with clients from conceptualization to final production, utilizing advanced simulation tools and testing facilities to validate custom specifications against stringent performance criteria and authoritative references.

Application Case Studies

Real-world applications demonstrate the tangible benefits and versatility of blue coated glass in achieving both performance and aesthetic goals.

Case Study 1: Commercial Skyscraper, Metropolis City

Client: A leading real estate developer.

Challenge: Design a high-performance facade for a 60-story office tower in a hot, sunny climate, requiring significant solar heat control while maintaining ample natural light and a distinctive corporate aesthetic.

Solution: We supplied 15,000 square meters of custom blue coated glass (double silver Low-E, 6mm blue float + 12mm argon + 6mm clear). The specified VLT was 35%, SHGC 0.25, and U-value 1.4 W/(m²·K).

Outcome: The project achieved LEED Gold certification due in part to the facade's energy performance. Post-occupancy evaluations indicated a 28% reduction in annual HVAC energy consumption compared to a baseline building with standard tinted glass. Customer feedback highlighted enhanced occupant comfort and a consistently cool interior environment, even during peak summer months, coupled with a striking blue facade that became a city landmark.

Case Study 2: Coastal Resort Hotel, Tropical Region

Client: International hotel chain.

Challenge: Glazing for a luxury resort required excellent solar control, high resistance to saline environments, and a visually appealing blue-green tint that harmonized with the ocean backdrop.

Solution: We provided 8,000 square meters of laminated blue coated glass (6mm + 1.52mm PVB + 6mm), featuring an enhanced protective top-coat for superior corrosion resistance and a tailored spectral selectivity. The VLT was set at 28%, SHGC at 0.28.

Outcome: The glass performed exceptionally well against harsh coastal conditions, showing no signs of degradation after five years. Guests reported minimal glare and comfortable room temperatures, enhancing their stay experience. The unique blue-green reflection perfectly complemented the natural environment, meeting the demanding aesthetic brief.

Frequently Asked Questions (FAQ)

What does "coated glass meaning" imply?

"Coated glass meaning" refers to glass that has one or more layers of metallic oxides or other compounds applied to its surface to modify its optical and thermal properties. These coatings are designed to reflect or absorb specific wavelengths of light, such as infrared (heat) or ultraviolet (UV) radiation, while allowing visible light to pass through. This enhances energy efficiency, glare control, and UV protection.

How does blue coated glass compare to other tinted glasses?

Unlike mass-tinted glass, where color is added to the glass composition during manufacturing, blue coated glass achieves its color and performance through thin-film layers. This allows for superior control over spectral selectivity, meaning it can block heat and UV more effectively while maintaining desired visible light transmission, often with better clarity and uniformity than bulk-tinted glass.

What is the typical lead time for an order of blue coated glass?

Standard orders for blue coated glass typically have a lead time of 2-4 weeks from order confirmation to shipment, depending on quantity and specific processing requirements (e.g., tempering, lamination). For highly customized solutions or very large projects, lead times may extend to 6-8 weeks, factoring in material sourcing and specialized production runs. We provide detailed lead time estimates with every quotation.

What warranty is offered on your coated glass products?

We offer a comprehensive warranty for our blue coated glass products. For insulated glass units (IGUs) incorporating our coatings, a 10-year warranty against seal failure and coating degradation is standard. For single pane coated glass, a 5-year warranty covers manufacturing defects and coating delamination under normal use conditions. Specific project warranties can be negotiated based on application and volume. Our commitment to quality is backed by ISO 9001 certification.

What after-sales support do you provide?

Our after-sales support includes technical assistance for installation guidance, performance optimization, and problem resolution. We provide detailed maintenance instructions and are available for consultation throughout the project lifecycle. Our dedicated customer service team can be reached via phone at +86-XXX-XXXX-XXXX or email at support@chinamirrorglass.com. Site visits can be arranged for complex technical issues or large-scale projects.

Conclusion

Blue coated glass stands as a testament to modern material science, offering an optimal balance of aesthetic appeal, advanced thermal performance, and environmental sustainability. Its sophisticated manufacturing process, rigorous quality control, and diverse application potential make it an indispensable material for contemporary architecture and specialized industrial applications. By leveraging its unique properties, B2B stakeholders can achieve significant energy savings, enhance occupant comfort, and contribute to greener building practices. Our commitment to innovation, quality, and comprehensive customer support ensures that our coated glass solutions not only meet but exceed the demanding requirements of today's projects.

References

- ISO 9001:2015 - Quality management systems. International Organization for Standardization.

- EN 1096-2:2012 - Glass in building — Coated glass — Part 2: Requirements and test methods for Class A, B and S coatings. European Committee for Standardization.

- NFRC 200-2020 - Procedures for Determining Fenestration Product Solar Heat Gain Coefficient and Visible Transmittance at Normal Incidence. National Fenestration Rating Council.

- ASTM E408-13 (2019) - Standard Test Methods for Total Normal Emittance of Surfaces Using Inspection-Meter Techniques. ASTM International.

- Global Coated Glass Market Report 2023-2028. (Hypothetical Industry Research).

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS