Aug . 31, 2025 04:00 Back to list

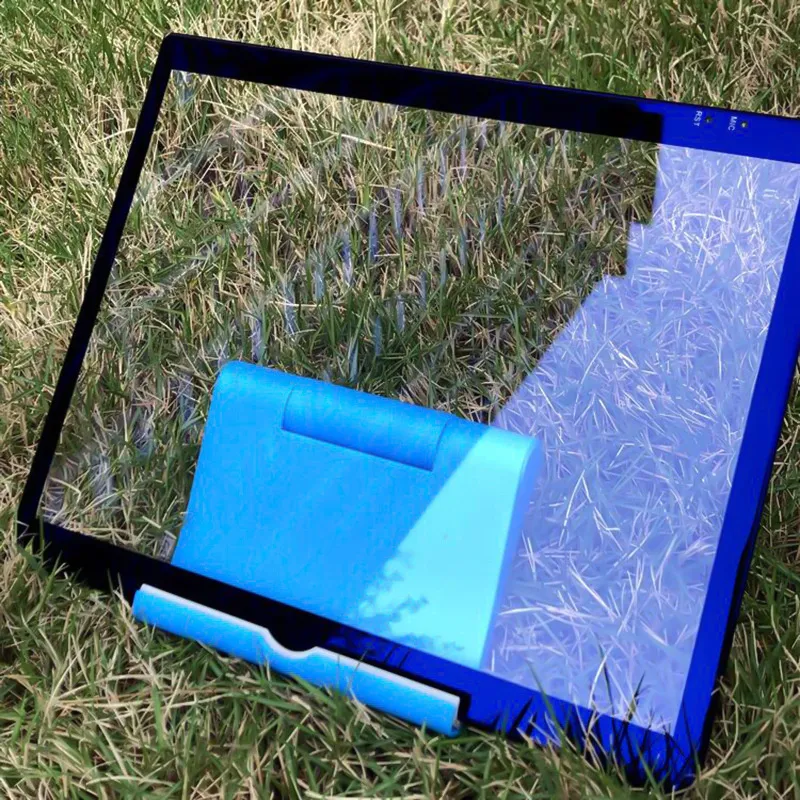

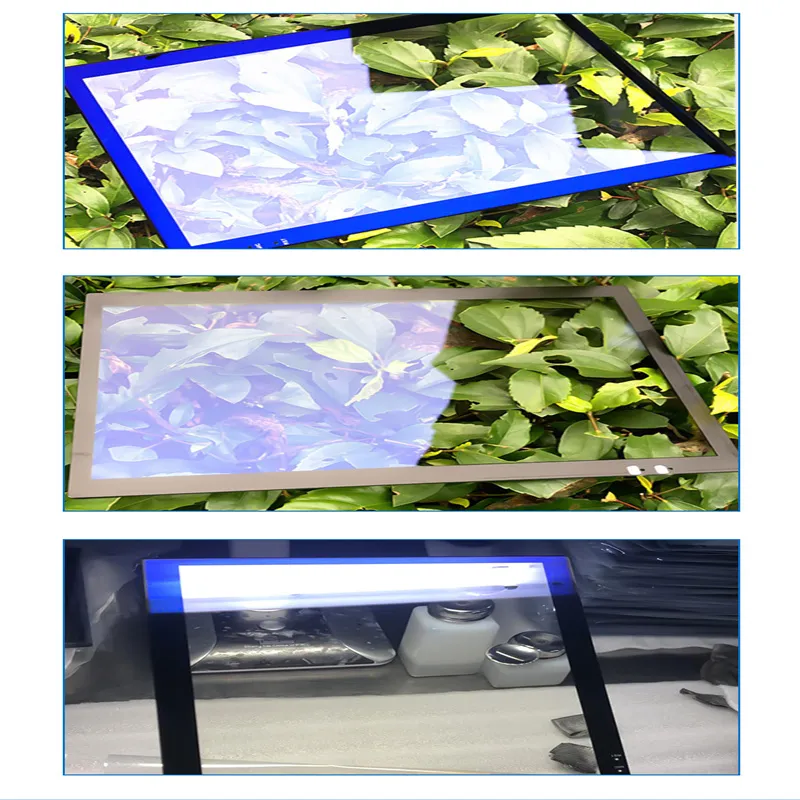

Premium Anti-Glare Etched Glass | Superior Clarity & Durability

Advancements in Display Technology: The Demand for Anti-Glare Solutions

In an increasingly digital world, the quality of visual interfaces is paramount. From industrial control panels to high-definition public displays, the clarity and legibility of screens directly impact operational efficiency, safety, and user experience. A significant challenge in diverse environments is mitigating glare and reflections, which can obscure critical information, cause eye strain, and diminish the overall effectiveness of displays. This has driven a robust demand for advanced anti-glare solutions, particularly high-performance etched glass.

The market for specialized display components is undergoing rapid evolution, influenced by trends such as the proliferation of outdoor displays, the integration of touch technology in harsh industrial settings, and the increasing reliance on large-format interactive screens. These applications frequently encounter ambient light conditions, from direct sunlight to intense artificial lighting, making standard glass unsuitable. Innovations in surface treatment technologies, specifically chemical etching, have emerged as the leading method to produce superior anti-glare properties without sacrificing optical clarity or durability. This article delves into the technical aspects, applications, and strategic advantages of premium anti glare etched glass, a critical component for next-generation visual systems.

The Manufacturing Process of Premium Anti-Glare Etched Glass

The production of premium anti glare etched glass is a sophisticated, multi-stage process that combines precision engineering with advanced chemical treatments. Unlike simple coatings, etching physically modifies the glass surface, creating a microscopic texture that diffuses incident light rather than reflecting it directly. This results in a highly durable, low-reflectivity surface.

Process Flow Overview:

- Substrate Selection and Preparation: High-quality float glass, typically soda-lime or borosilicate, is selected for its optical purity and structural integrity. The glass undergoes rigorous cleaning to remove contaminants, ensuring optimal adhesion and uniform etching.

- Masking (Optional for Patterned Etching): For specific aesthetic or functional requirements, areas of the glass can be masked with a protective layer, preventing etching in those regions. This allows for clear "windows" or specific design elements.

- Chemical Etching: The prepared glass is immersed in a specialized acid solution, often a hydrofluoric acid derivative, under precisely controlled temperature and time parameters. The etching process creates a uniformly textured surface characterized by microscopic peaks and valleys. The size and distribution of these features dictate the level of haze and gloss, critical parameters for anti-glare performance. Advanced techniques ensure a consistent etch depth across large panels.

- Neutralization and Rinsing: After etching, the glass is thoroughly rinsed to remove all chemical residues, followed by a neutralization bath to stabilize the surface and prevent further reaction.

- Drying and Inspection: The etched glass is carefully dried, typically in a cleanroom environment, to prevent spotting. Each panel undergoes meticulous optical inspection for uniformity, clarity, haze level, and the absence of defects.

- Post-Processing (Optional): Depending on application requirements, additional treatments such as oleophobic coatings (for smudge resistance) or tempering (for enhanced strength) may be applied.

Materials, Manufacturing Processes, and Testing Standards:

- Materials: Typically low-iron float glass for optimal clarity, with options for chemically strengthened or thermally tempered substrates depending on mechanical requirements.

- Processes: Chemical etching is the primary surface modification. While processes like casting or CNC machining are relevant for shaping glass, the anti-glare property is achieved through surface chemistry, not mechanical removal for this product. Precision robotic handling systems are often employed to ensure consistency and prevent damage during processing.

- Testing Standards: Quality assurance adheres to international standards such as ISO 9001 for quality management systems. Specific optical properties are tested against ASTM D1003 (haze and luminous transmittance), ASTM D523 (specular gloss), and MIL-STD-810G (environmental durability). Mechanical strength tests conform to ANSI Z97.1 for safety glazing materials.

- Service Life: Due to the inherent durability of etched glass (a physical surface modification, not a coating), its anti-glare properties are highly resistant to wear, scratches, and environmental degradation, offering a service life often exceeding 10-15 years in typical operational conditions, significantly outperforming coated alternatives.

Target Industries and Application Advantages:

The robust characteristics of premium anti glare etched glass make it indispensable across a range of demanding B2B sectors:

- Petrochemical & Energy: For control room displays, HMI panels in hazardous areas, and outdoor monitoring stations, anti-glare properties are crucial for real-time data readability, enhancing safety and preventing costly errors. Its inherent corrosion resistance against common industrial chemicals is a significant advantage.

- Metallurgy & Heavy Industry: Display screens on machinery, large format process monitors, and operator consoles benefit from improved visibility under high ambient light conditions, dust, and corrosive fumes, leading to better operational control and reduced operator fatigue.

- Water Supply & Drainage: Control systems for pumps, valves, and monitoring equipment often operate in humid or outdoor environments. Anti-glare etched glass ensures reliable display performance, crucial for managing critical infrastructure. The etched surface is also less prone to water sheeting, maintaining clarity even when wet.

- Transportation (Automotive, Marine, Avionics): Dashboard displays, infotainment systems, and navigational screens require optimal readability in varying light conditions, from direct sunlight to low-light settings. The diffused reflection minimizes glare, ensuring critical information is always accessible.

- Medical & Healthcare: Diagnostic imaging displays, surgical monitors, and patient information screens demand high clarity and minimal reflections to ensure accurate interpretation and reduce clinician eye strain. Etched glass maintains a sterile surface better than some coated options.

In these scenarios, advantages like enhanced energy saving (by reducing the need for higher backlight intensity), superior corrosion resistance, and robust mechanical durability translate directly into lower total cost of ownership and improved operational reliability.

Technical Specifications and Performance Metrics

The performance of premium anti glare etched glass is quantifiable through several key technical parameters. These metrics are critical for engineers and procurement specialists to select the optimal solution for their specific display requirements.

Key Optical and Mechanical Parameters:

| Parameter | Measurement Unit | Typical Range/Value | Significance |

|---|---|---|---|

| Reflectance (Gloss 60°) | % | < 1.0% - 10.0% (depending on etch level) | Lower values indicate superior anti-glare performance. Standard float glass is typically 80-90%. |

| Haze (ASTM D1003) | % | 1% - 15% (application dependent) | Measures light scattering. Optimal haze balances glare reduction with image clarity. |

| Transmittance | % | > 90% (visible light) | Percentage of light passing through the glass. High transmittance is crucial for display brightness. |

| Surface Hardness (Mohs) | N/A | 6-7 | Resistance to scratching, similar to unetched glass, superior to many coatings. |

| Thickness Tolerance | mm | ± 0.1mm - ± 0.2mm | Critical for integration into precise display assemblies. |

| Operating Temperature Range | °C | -40 to +120 | Ensures performance in extreme environments without degradation. |

The selection of the appropriate anti-glare etched glass involves a careful balance of haze, gloss, and transmission properties. For instance, a higher haze level offers more aggressive glare diffusion but can slightly reduce perceived sharpness. Conversely, a lower haze maintains crispness but offers less glare reduction. Tailored etching processes allow manufacturers to fine-tune these parameters to meet specific application demands, such as high-resolution outdoor signage versus indoor touch panels requiring minimal image degradation.

Technical Advantages and Application Scenarios

The inherent properties of premium anti glare etched glass provide distinct technical advantages over alternative anti-glare solutions, making it the preferred choice for mission-critical and high-performance applications. Its permanent surface modification ensures long-term stability and performance.

Core Advantages:

- Superior Durability: Unlike anti-glare coatings, which can scratch, peel, or degrade over time due to UV exposure or chemical contact, the etched surface is an integral part of the glass. This provides unmatched resistance to abrasion, chemicals, and environmental stressors, leading to extended service life and reduced maintenance.

- Consistent Optical Performance: The etching process creates a highly uniform surface texture, ensuring consistent glare diffusion across the entire panel. This eliminates "hot spots" or variations in clarity often seen with lower-quality solutions, crucial for large-format displays.

- Enhanced Tactile Experience: For touch-enabled displays, the subtly textured surface of etched glass offers a smoother, more tactile feel than many coated alternatives, reducing finger drag and improving responsiveness. It also minimizes smudging and makes fingerprints less visible.

- Chemical and Environmental Resistance: The material properties of glass, combined with the etching process, confer excellent resistance to a wide range of industrial chemicals, cleaning agents, and extreme temperature fluctuations. This is vital for industrial, medical, and outdoor applications.

- Maintenance of Light Transmission: While diffusing glare, etched glass maintains a high level of light transmission, ensuring display brightness and color vibrancy are not significantly compromised. This can contribute to energy savings by allowing displays to operate effectively at lower backlight settings.

Specific Application Scenarios and Benefits:

- Outdoor Kiosks and Digital Signage: In public spaces, direct sunlight and varying ambient light levels are constant challenges. Anti-glare etched glass ensures messages are always legible, maximizing advertising effectiveness and information dissemination. Its durability protects against vandalism and weather.

- Industrial HMI (Human-Machine Interface): Control panels in manufacturing plants, heavy machinery, and processing facilities often operate under bright factory lighting or near windows. Etched glass allows operators to clearly view critical data, increasing operational safety and precision.

- Marine and Avionics Displays: Cockpit displays, bridge navigation systems, and radar screens demand absolute clarity under extreme glare conditions, such as reflections off water or clouds. The superior glare diffusion of etched glass is crucial for safety and navigation.

- Medical Equipment: Surgical monitors, patient vital sign displays, and diagnostic screens in operating rooms and clinics benefit from minimized reflections, which can distract clinicians and hinder accurate interpretation.

- Gaming and Arcade Machines: For interactive entertainment, vibrant visuals and responsiveness are key. Anti-glare etched glass enhances the user experience by eliminating reflections that can disrupt gameplay, ensuring crisp images even in brightly lit arcades.

Vendor Comparison and Customization Options

The market for anti-glare solutions offers various options, but for demanding B2B applications, the choice often narrows to the superior performance and durability of etched glass. Understanding the distinctions between different types and vendors is crucial for informed decision-making.

Comparison: Etched Glass vs. Anti-Glare Coatings:

| Feature | Etched Glass (Premium Anti-Glare Etched Glass) | Anti-Glare (AG) Coating | Anti-Reflective (AR) Coating |

|---|---|---|---|

| Glare Reduction Mechanism | Surface texture (diffusion) | Surface texture (diffusion) via applied layer | Interference (reduces internal reflections) |

| Durability (Scratch/Chemical) | Excellent (part of glass structure) | Moderate (can scratch/peel) | Moderate (can scratch) |

| Optical Clarity | High (controlled haze) | Good (can be inconsistent) | Excellent (very low reflectance) |

| Cost | Higher initial (long-term value) | Moderate | High |

| Service Life | Very Long (10+ years) | Moderate (2-5 years typical) | Moderate (3-7 years typical) |

| Ideal Use Case | Industrial, Outdoor, Medical, Touch Displays requiring extreme durability. | Consumer electronics, less demanding environments. | High-end indoor displays where ultimate clarity trumps anti-glare, often combined with AG for best results. |

Customized Solutions:

Recognizing that no two projects are identical, leading manufacturers of anti-glare etched glass offer extensive customization capabilities. This ensures that the final product integrates seamlessly and performs optimally within specific system designs.

- Tailored Haze and Gloss Levels: The etching process can be precisely controlled to achieve specific haze (e.g., 1%, 5%, 10%) and gloss levels (e.g., 60°, 90°), balancing glare reduction with image clarity according to application needs (e.g., lower haze for medical imaging, higher haze for outdoor digital signage).

- Size and Shape Customization: Glass can be supplied in custom dimensions, shapes (e.g., circular, irregular polygons), and with precision edge work (e.g., polished edges, bevels, notches) to fit unique enclosure designs.

- Integrated Strengthening Options: Chemically strengthened (e.g., Gorilla Glass, Dragontrail) or thermally tempered glass substrates can be used to enhance impact resistance and mechanical strength, crucial for public-facing or rugged industrial displays.

- Additional Coatings: While etching provides anti-glare, additional coatings can be applied on the non-etched side or on top of the etched surface for specific functionalities, such as anti-reflective (AR) coatings for ultra-low reflectivity, oleophobic coatings for smudge resistance, or antimicrobial coatings for hygienic environments.

- Patterned Etching: Specific areas of the glass can be selectively etched, allowing for clear windows for sensors or cameras, or to create unique design elements.

Engaging with a vendor that demonstrates deep technical expertise and offers comprehensive customization services is paramount. This ensures that the supplied anti-glare glass is not just a component, but a perfectly engineered solution that contributes to the overall success of the final product.

Application Case Studies and Customer Experience

Real-world implementations underscore the tangible benefits of integrating premium anti glare etched glass into diverse B2B applications. These case studies highlight improved performance, enhanced user satisfaction, and long-term cost efficiencies.

Case Study 1: Outdoor Public Information Kiosks

A major metropolitan transport authority faced significant challenges with readability on its outdoor public information kiosks. Standard laminated glass screens suffered from severe glare, especially during peak sunlight hours, rendering critical transit information unreadable. After implementing customized anti-glare etched glass panels (with a 10% haze level for maximum diffusion) on 55-inch touch displays, user feedback drastically improved. The etched glass ensured 24/7 legibility, even in direct sunlight, and its robust surface withstood continuous public interaction and exposure to varying weather conditions for over five years without degradation. The transport authority reported a 30% reduction in user complaints related to screen visibility and an increase in overall system reliability.

Case Study 2: Petrochemical Control Room Displays

A leading petrochemical plant sought to upgrade its central control room displays, requiring exceptional clarity and minimal reflections to monitor complex processes. Previous displays, using conventional anti-glare coatings, exhibited wear and inconsistent performance under the plant's continuous operation and occasional chemical exposure. By integrating large-format (80-inch) panels of anti-glare etched glass, the plant achieved significantly improved visual acuity for operators. The etched surface provided a uniform, reflection-free viewing experience, reducing eye strain during long shifts. Furthermore, the inherent chemical resistance of the etched glass proved invaluable, ensuring that accidental exposure to cleaning agents or airborne chemicals did not compromise the display's integrity or optical properties, contributing to uninterrupted operational oversight and safety.

Customer Feedback & Experience:

"The transition to etched anti-glare panels for our surgical monitors was transformative. The clarity and lack of reflection ensure our surgeons have an uncompromised view, which is absolutely critical. The durability means we don't worry about frequent replacements, making it a sound investment."

"For our new generation of heavy industrial HMI panels, we needed a solution that could withstand extreme conditions and provide perfect visibility. The customized premium anti glare etched glass exceeded our expectations in every aspect, particularly its resistance to impacts and chemical abrasion. It's a game-changer for operator efficiency and safety."

These testimonials exemplify the consistent value proposition: enhanced performance, reduced operational friction, and long-term reliability in demanding environments, all facilitated by the superior characteristics of anti-glare etched glass.

Commitment to Quality and Customer Trust

Building long-term partnerships in the B2B sector requires unwavering commitment to quality, transparency, and robust support. Providers of premium anti glare etched glass must demonstrate this through certifications, clear operational policies, and accessible customer service.

Quality Assurance and Certifications:

- ISO 9001:2015 Certified: Adherence to an internationally recognized Quality Management System ensures consistent product quality and continuous improvement across all manufacturing processes.

- RoHS and REACH Compliance: Products meet strict environmental and hazardous substance regulations, confirming responsible manufacturing practices.

- Compliance with Industry Standards: Our products are tested to meet or exceed relevant industry standards, including optical performance per ASTM D1003, mechanical durability standards like ANSI Z97.1, and environmental testing against MIL-STD-810G protocols, where applicable.

- Trusted Partnerships: Decades of service supplying critical components to Fortune 500 companies and specialized B2B manufacturers demonstrate our proven track record and reliability in delivering high-performance glass solutions.

Frequently Asked Questions (FAQ):

Q: What is the primary difference between anti-glare etched glass and anti-reflective coated glass?

A: Anti-glare etched glass physically diffuses light using a textured surface, reducing specular reflections and providing a matte finish. Anti-reflective coated glass uses optical interference to minimize reflections, often resulting in a very clear, almost invisible appearance. While AR coatings offer superior light transmission, they are generally less durable than etched glass and do not diffuse glare as effectively as etching in high ambient light conditions. Often, a combination of both can be used for optimal performance.

Q: Can anti-glare etched glass be used with touch screens?

A: Absolutely. Etched glass is an excellent choice for touch screens. Its subtly textured surface reduces finger drag, enhances tactile feel, and minimizes the visibility of fingerprints and smudges, improving the overall user experience and reducing maintenance needs compared to glossy surfaces.

Q: What is the typical lead time for custom orders?

A: Lead times vary depending on the complexity of customization, quantity, and current production schedule. For standard etched glass in common sizes, lead times can range from 3-4 weeks. For highly customized or large-volume orders, a typical lead time might be 6-8 weeks, following sample approval. We work closely with clients to establish realistic timelines and manage expectations.

Warranty and After-Sales Support:

All our premium anti glare etched glass products are backed by a comprehensive 2-year manufacturer's warranty against defects in materials and workmanship. This covers issues related to optical performance, etching uniformity, and structural integrity under normal operating conditions. Our dedicated after-sales support team is available to assist with any technical inquiries, installation guidance, or performance assessments, ensuring your continued satisfaction and optimal product integration.

For further assistance, technical datasheets, or to discuss specific project requirements, please contact our expert team via the provided channels on our website. We are committed to providing unparalleled support from initial consultation through to post-installation.

Conclusion

The strategic integration of premium anti glare etched glass represents a critical advancement for B2B enterprises seeking to optimize visual performance in challenging environments. Its superior durability, consistent optical properties, and resistance to environmental stressors make it an indispensable component for industrial HMIs, outdoor displays, medical equipment, and other mission-critical applications. By understanding the intricate manufacturing processes, technical specifications, and the vast customization potential, businesses can leverage this advanced material to enhance operational efficiency, improve user experience, and ensure long-term reliability of their display systems. Partnering with experienced manufacturers committed to quality and comprehensive support ensures a tailored solution that meets the most rigorous demands of modern industry.

References

- ASTM D1003-13, "Standard Test Method for Haze and Luminous Transmittance of Transparent Plastics," ASTM International, West Conshohocken, PA, 2013.

- ASTM D523-14, "Standard Test Method for Specular Gloss," ASTM International, West Conshohocken, PA, 2014.

- ISO 9001:2015, "Quality management systems — Requirements," International Organization for Standardization, Geneva, Switzerland, 2015.

- MIL-STD-810G, "Environmental Engineering Considerations and Laboratory Tests," U.S. Department of Defense, 2008.

- ANSI Z97.1-2015, "Safety Glazing Materials Used in Buildings - Safety Performance Specifications and Methods of Test," American National Standards Institute, New York, NY, 2015.

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS