Jan . 13, 2025 17:29 Back to list

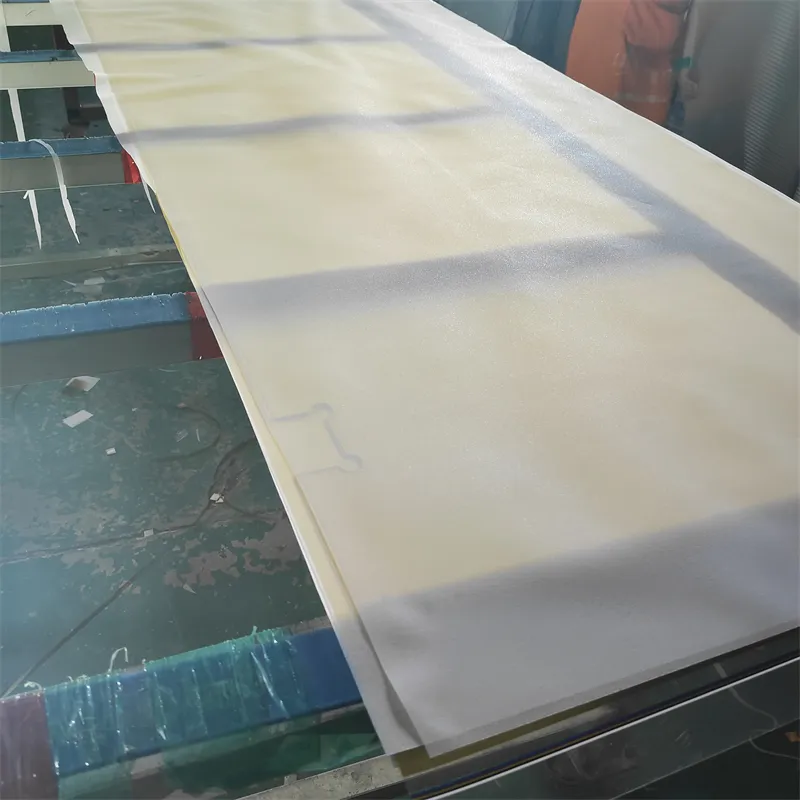

blue float glass

Float glass has become an imperative asset in various industries such as construction, automotive, and electronics due to its versatility and superior quality. As someone deeply entrenched in the industry, it's unmistakable how choosing the right float glass supplier can significantly impact the quality and efficiency of your projects. Understanding the intricacies of float glass manufacturing and supply can help businesses optimize their production processes and align with sustainability goals.

In-depth industry knowledge also reveals that optimal float glass suppliers offer customizable solutions. They work closely with clients to develop bespoke glass types that fit unique architectural or industrial needs, from solar-reflective coatings to various color tints or laminated finishing. Such customization not only meets aesthetic preferences but also enhances energy efficiency and environmental performance. Trust is a fundamental pillar in the supplier-client relationship. Reviewing case studies and client testimonials can provide insights into a supplier's reliability and consistency in product quality over time. Suppliers who openly share their production processes and allow facility visits tend to garner more trust, as transparency is a marker of integrity. Lastly, an effective float glass supplier keeps abreast of global market trends and innovations in glass technology. With the rising demand for eco-friendly construction materials, many leading suppliers have begun investing in research to produce glass that actively contributes to green building standards. Engaging with such forward-thinking suppliers can put your projects at the forefront of environmental consciousness. In conclusion, selecting a float glass supplier is a decision that should rest on careful consideration of their expertise, authority, trustworthiness, and experience. By aligning with suppliers who demonstrate these qualities, businesses can ensure consistent access to high-quality glass products while also contributing to sustainable and innovative practices in their respective industries.

In-depth industry knowledge also reveals that optimal float glass suppliers offer customizable solutions. They work closely with clients to develop bespoke glass types that fit unique architectural or industrial needs, from solar-reflective coatings to various color tints or laminated finishing. Such customization not only meets aesthetic preferences but also enhances energy efficiency and environmental performance. Trust is a fundamental pillar in the supplier-client relationship. Reviewing case studies and client testimonials can provide insights into a supplier's reliability and consistency in product quality over time. Suppliers who openly share their production processes and allow facility visits tend to garner more trust, as transparency is a marker of integrity. Lastly, an effective float glass supplier keeps abreast of global market trends and innovations in glass technology. With the rising demand for eco-friendly construction materials, many leading suppliers have begun investing in research to produce glass that actively contributes to green building standards. Engaging with such forward-thinking suppliers can put your projects at the forefront of environmental consciousness. In conclusion, selecting a float glass supplier is a decision that should rest on careful consideration of their expertise, authority, trustworthiness, and experience. By aligning with suppliers who demonstrate these qualities, businesses can ensure consistent access to high-quality glass products while also contributing to sustainable and innovative practices in their respective industries.

Next:

Latest news

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS