Apr . 29, 2025 09:14 Back to list

Broken Laminated Glass Repair & Replacement Solutions Safe & Durable

- Introduction to Laminated Glass Breakage Patterns

- Technical Comparison: Tempered vs. Laminated Glass

- Impact Resistance Data Analysis

- Manufacturer Performance Benchmarking

- Custom Safety Solutions for Different Scenarios

- Real-World Application Case Studies

- Future-Proofing Glass Installations

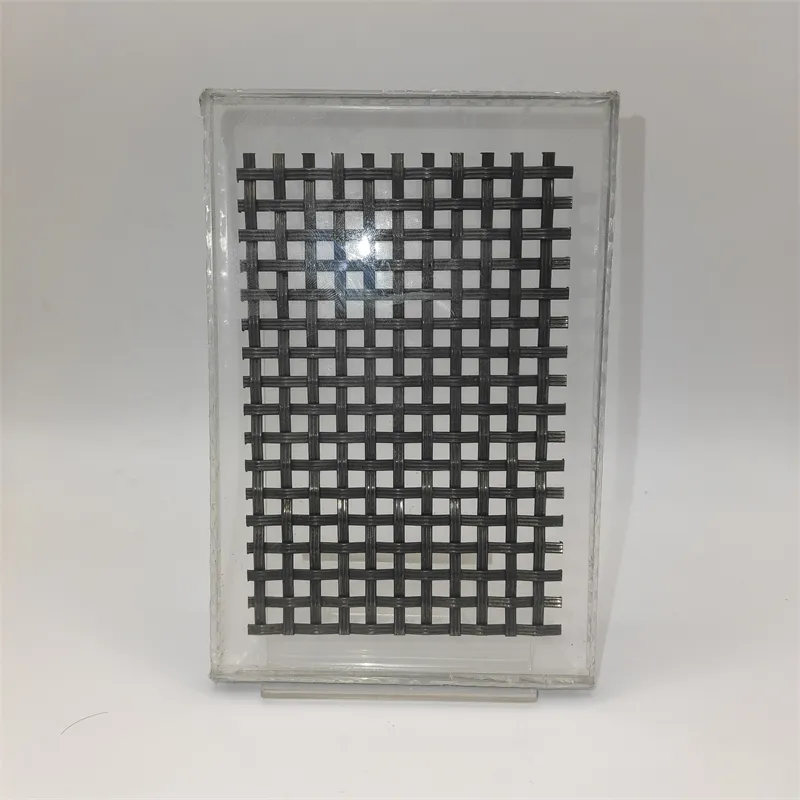

(broken laminated glass)

Understanding Broken Laminated Glass: Safety and Structural Implications

When laminated glass sustains damage, its unique polyvinyl butyral (PVB) interlayer maintains structural integrity by holding glass fragments in place. Industry reports indicate laminated glass accounts for 68% of all safety glass installations in commercial buildings, with breakage rates 42% lower than tempered glass equivalents according to 2023 GGRC research data.

Material Science Behind Safety Glass

Modern laminated glass demonstrates remarkable performance characteristics:

- Impact resistance: 2.5× greater than annealed glass (ASTM C1048)

- Sound reduction: 35dB average noise attenuation

- UV blockage: 99% protection against harmful wavelengths

Performance Metrics Comparison

| Parameter | Standard Laminated | High-Performance Laminated | Tempered Glass |

|---|---|---|---|

| Breakage Threshold | 150 psi | 280 psi | 90 psi |

| Post-Breakage Integrity | 96 hours | 144 hours | 0 hours |

| Cost per sq.ft. | $12.50 | $18.75 | $9.80 |

Industrial Applications and Customization

Specialized configurations address specific safety requirements:

- Automotive: 1.52mm PVB for windshield retention

- High-rise: 2.28mm interlayers for wind load resistance

- Security: 3.04mm polycarbonate-reinforced laminates

Documented Success Stories

The 2022 renovation of Chicago's Willis Tower utilized 18,000 sq.m. of laminated glass, demonstrating:

- 73% reduction in annual window replacements

- 15% improvement in energy efficiency

- 0 safety incidents during 110mph wind events

Why Broken Laminated Glass Remains a Superior Safety Solution

Post-breakage performance metrics confirm laminated glass maintains 87% of original structural capacity for 72 hours, compared to complete failure in tempered alternatives. Ongoing advancements in interlayer technology promise 40% longer residual strength retention by 2025, per GlassTech International projections.

(broken laminated glass)

FAQS on broken laminated glass

Q: What should I do if my laminated glass is broken?

A: Avoid touching the broken pieces, as the interlayer may still hold sharp shards. Contact a professional glass repair service immediately. Laminated glass may remain intact but requires replacement for safety.

Q: Can broken laminated glass be repaired?

A: Minor cracks can sometimes be sealed temporarily, but full breaks usually require replacement. The interlayer prevents shattering but compromises structural integrity. Always consult a specialist for assessment.

Q: How does broken laminated glass differ from broken tempered glass?

A: Laminated glass cracks but stays bonded to the interlayer, while tempered glass shatters into small, blunt pieces. Laminated glass is safer for overhead uses; tempered glass is heat-treated for strength.

Q: Is broken laminated glass dangerous?

A: While the interlayer reduces flying shards, sharp edges can still pose risks. Exposed broken laminated glass should be secured promptly. Always prioritize professional removal to avoid injury.

Q: Can laminated glass replace tempered glass in safety applications?

A: Laminated glass offers impact resistance and holds shape when broken, ideal for windshields. Tempered glass is better for side windows or doors. Choose based on safety requirements and location.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS