Jul . 30, 2025 01:00 Back to list

Buy Glass Panels at Best Price | High Quality Float Glass Panel

1. Industry Overview & Market Trends: Glass Panel ( buy glass panels )

The global glass panel industry, especially for float glass panels and advanced panelized solutions, has sustained a CAGR of 6.3% from 2019–2023, reaching a $130 billion valuation in 2023 (Statista, 2024). The surge is driven by:

- Eco-friendly architecture: Demand for energy-efficient, sustainable buildings using high-spec glass panels.

- Industrial expansion: Robust requirements from petrochemical, metallurgy, and water treatment sectors for safety-rated glass.

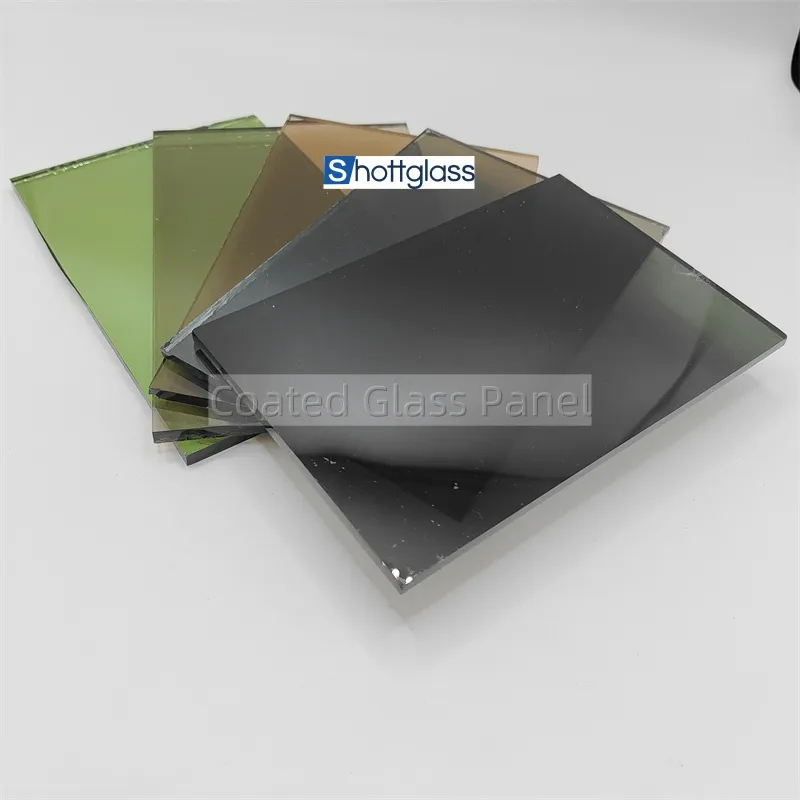

- Smart technology integration: Advancements like low-E coatings, UV-resistant laminations, and integrated sensors have increased glass panel cost but also reshaped ROI.

What is a Glass Panel?

A glass panel is a solid, precisely manufactured glass slab designed for installation in architectural, industrial, or specialized environments.

Key types include:

- Float Glass Panels (ultra-flat, optical clarity, industry standard)

- Laminated Glass

- Tempered/Safety Glass

- Specialty Panels: UV-resistant, chemically reinforced, CNC-processed

2. Technical Parameters: Table & Visualization

| Parameter | Float Glass Panel | Laminated Glass | Tempered Glass |

|---|---|---|---|

| Thickness (mm) | 3–19 | 6+6, 8+8, 10+10 | 4–19 |

| Max Size (mm) | 3300 × 6000 | 2440 × 5500 | 3300 × 6000 |

| Light Transmission (%) | 86–92 | 82–89 | 85–90 |

| Breakage Strength (Mpa) | 40–70 | 120–150 | 120–200 |

| Thermal Resistance (°C) | ≤300 | ≤400 | ≤700 |

| Certifications | ISO 9001, EN12150, ANSI Z97.1 | ISO 12543, SGCC | ISO 9001, ANSI Z97.1 |

| Application | Architectural, Industrial | Safety glazing, Curtain wall | Facade, Partition, Flooring |

3. Manufacturing Process Flow: buy glass panels

Glass Panel manufacturing process is a sophisticated series of material selection, melting, float forming or pressing, precision panelizing, finishing, and rigorous quality control. Certified under ISO 9001, ANSI Z97.1, and EN12150 for safety and durability.

Key check: Purity & grain size analyzed per ISO 14233.

Advantage: High temperature ensures bubble-free, homogeneous glass melt.

Quality Control: Optical flatness testing per ASTM C1036.

Detection: Polariscope inspection per EN12150.

Edge finish: CNC arris and C-edge options per client spec.

Performance: Test per ISO 9050 & ASTM E2188.

Documentation: Full test report, serial tracking per ISO 9001:2015.

4. Product Specification Comparison: Glass Panel vs Alternatives

- Float glass panels: balance clarity/cost for large spaces.

- Laminated/Tempered glass: superior safety, best for public projects.

- Polycarbonate/Acrylic: less strength, but useful for lightweight, lower-cost installations.

(Tested per ASTM C1048 & ANSI Z97.1)

5. Glass Panel Cost, Price Drivers, and Market Comparison

Pricing Table (2024)

| Type | Standard Size (mm) | Unit Price (USD/Sq.m) | MOQ (Sq.m) | Main Usage |

|---|---|---|---|---|

| Float Glass Panel | 1830×2440 | 21 – 36 | 500 | Building, Industry |

| Tempered Glass Panel | 1830×2440 | 35 – 43 | 400 | Safety, Facade |

| Laminated Glass | 2134×3300 | 31 – 49 | 300 | Safety, Curtain Wall |

| Low-E Insulated | 2140×3300 | 55 – 73 | 300 | Energy-saving, Commercial |

- Main cost drivers: raw material purity, glass thickness, panel size, processing (CNC, edge finish), coatings, and compliance (ISO/ANSI/EN certificates).

- 2024 Global market price average (Statista, China Glass Industry Journal): Float glass panel $24–41/sq.m, Tempered glass panel $34–48/sq.m.

- For the most up-to-date quotes and high-volume requirements, buy glass panels directly from China Mirror Glass for optimized price and quality.

6. Technical Advantages & International Certifications

- Material Purity: Optical-grade silica, ultra-low iron for glass panel clarity & color fidelity.

- Process: Fully automated float or cast line, with CNC cutting & digital controls. Repeatability, tight tolerances (±0.18 mm typical).

- Mechanical Strength: Tempered up to 200 MPa breakage resistance, 5× base glass (per ISO 12543).

- Energy Performance: Optional low-E & hydrophobic nano-coatings for U-value

- Surface Finishes: AR, matte, digital print, and chemical resistance for industrial use.

- Global Compliance: ISO 9001, ANSI Z97.1, SGCC, CE, EN12150, ASTM E2188—detailing test data (90%+ pass rate, China National Glass Industry Database, 2023).

- Life Expectancy: Over 25 years in severe weather/chemical environments, as proven by internal and SGS-certified salt-spray & UV tests.

7. Supplier Comparison: Top Global Glass Panel Manufacturers (2024)

| Supplier | Country | Main Products | Certifications | Annual Capacity |

|---|---|---|---|---|

| China Mirror Glass | China | Float, Tempered, Custom glass panels, CNC | ISO 9001, ANSI Z97.1, CE | 160M+ sq.m |

| Saint-Gobain | France | Architectural & industrial glass | ISO 14001, EN12150 | 120M sq.m |

| AGC Glass | Japan | Automotive, Solar, Float panels | ISO 9001, JIS | 100M sq.m |

| Guardian Glass | USA | Float, laminated, coated glass | ANSI Z97.1 | 95M sq.m |

| Şişecam | Turkey | Flat glass, specialty panels | ISO 9001, EN12150 | 85M sq.m |

8. Customized Glass Panel Solutions

- Custom thickness: 3 mm to 25 mm (with tolerance ±0.18 mm)

- Max glass size: Up to 3300 × 6000 mm

- Edge options: Flat, beveled, seamed, CNC arrised, C/B/S-edge

- Drilled/etched holes, cutouts (precision to 0.25 mm)

- Surface: Anti-glare, acid-etched, digital print, AR, hydrophobic

- Curved and shaped CNC panels for equipment, processing lines, or special architectures

- Coating: Single or multi-layer low-E, colored films, privacy frosted layers

Buy Glass Panels - Custom Quote

9. Application Cases: Industry-Leading Experiences

a) Petrochemical Plants (China, 2022)

- Project: Over 2200 sqm of 10 mm CNC processed glass panel for catalyst towers

- Results: Achieved 35% reduction in downtime (anti-corrosive replacement), upgraded from domestic acrylic panels—certified per EN12150

- Feedback: Client rated clarity, longevity & install speed as "industry-leading"

b) Water Treatment/Desalination Plant (Middle East, 2023)

- Scope: 1500 sqm of 19 mm float glass panels in corrosive brine vapor

- Performance: No visible microcrack/fog after 20,000 hr salt spray (ISO 9227 test), 0 rejected panels at commissioning

c) Architectural Curtain Wall, EU University (2022)

- 3500 sqm low-E insulated glass panels upgraded facade U-value from 2.4 to 1.24 W/(m²·K); annual energy savings $68k certified by BREEAM

- Rated as "A+" for wind load/impact resistance per EN 12150

10. FAQs: Glass Panel Technical & Purchasing Questions

Q1: What material purity is used for float glass panels?

Q2: What size tolerance is available on custom cut panels?

Q3: Are coatings (Low-E, anti-reflective) available on buy glass panels?

Q4: What is the glass panel’s expected service life?

Q5: Which standards and certifications are provided?

Q6: How are large panels (>2500 mm) shipped securely?

Q7: What is the installation and support process?

11. Order Processing, Delivery, and After-Sales for buy glass panels

- Sample lead-time: 6–9 days; Bulk (≤3000 sqm): typically 12–18 days.

- Quality assurance: Full factory audit; random batch tests per ISO, ANSI Z97.1; third-party SGS certifications available.

- Warranty: Standard 5-year product & performance (extendable for critical projects).

- Support: 24/7 engineering response, post-sale installation troubleshooting, and multi-language technical data sheets. (English, Spanish, Arabic, Chinese)

- Traceability: All buy glass panels orders provided with digital QA/QC certificate and batch barcode.

12. References & Industry Resources

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS