Jul . 29, 2025 21:00 Back to list

Premium Laminated Glass Solutions: Safety & Clarity | 5mm, 6.38, 12mm Sheets & Doors

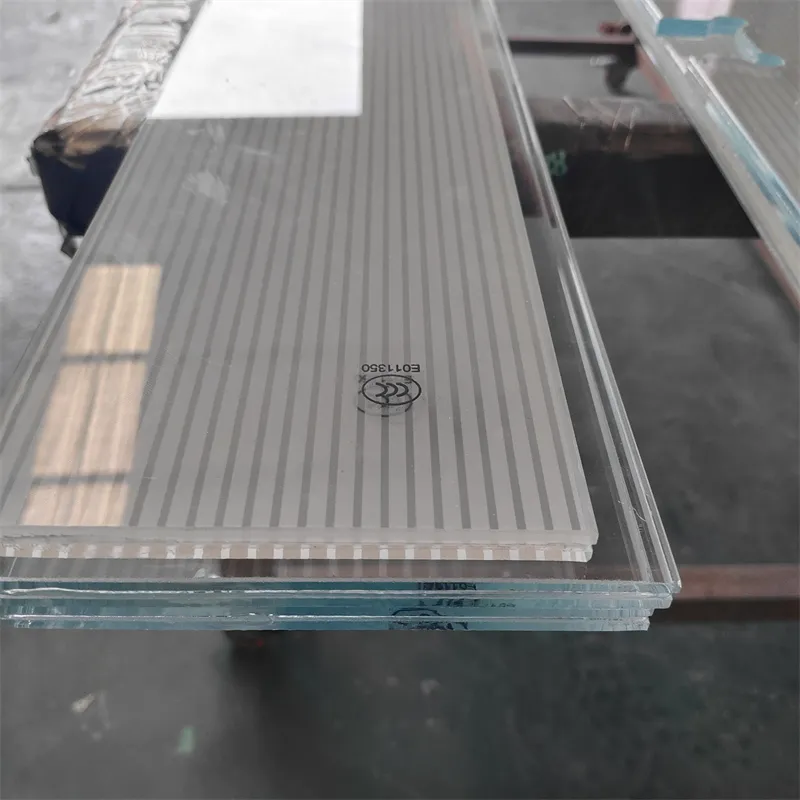

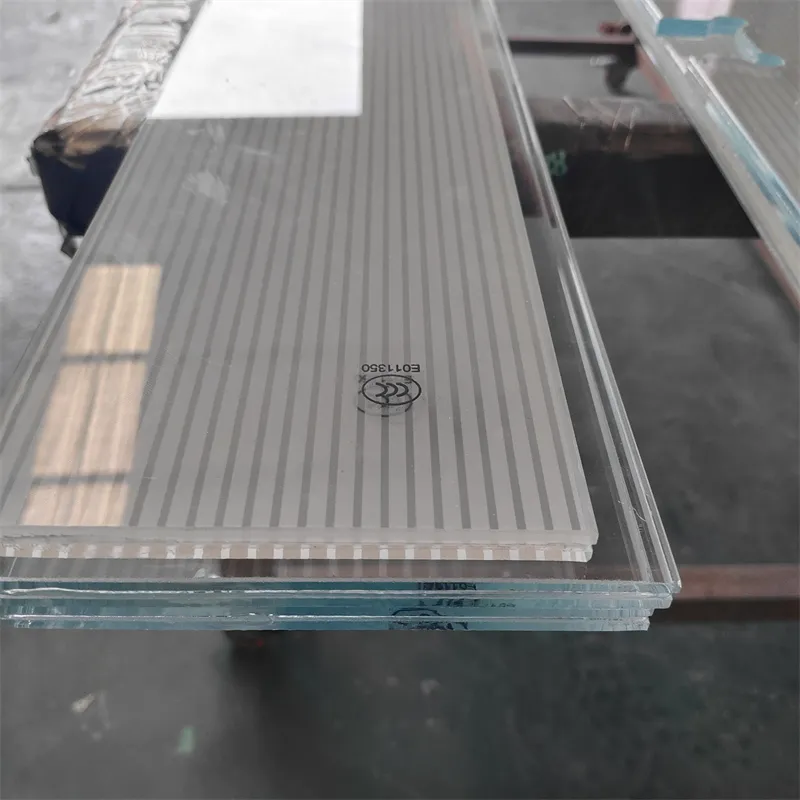

Laminated glass has reshaped architectural glazing and safety standards worldwide. From 5mm laminated glass for residential windows to robust 12mm laminated glass for structural doors, this advanced material is an industry benchmark in modern construction, transportation, and industrial sectors.

Laminated glass consists of two or more glass layers bonded together with a polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA) interlayer using heat and pressure. This structure ensures high impact resistance, safety, and superior sound/thermal insulation, making it indispensable across various industries.

Explore full range:

laminated glass.

Market Overview & Trends (2024)

According to Glass Magazine 2024 report, the global laminated glass market size is projected to exceed USD 27.2 billion by 2027, fueled by growing demands in construction, automotive, and public safety sectors. Technological advances and regulatory mandates (ISO 12543, ANSI Z97.1) further drive its applications in safety glazing, bulletproof enclosures, and energy-efficient facades.

- Construction: Building facade, skylights, floorings

- Automotive: Windshields, sunroofs

- Rail Transit: Cockpit shields, platform barriers

- Industrial: Machinery observation windows, chemical plants

- Marine & Aerospace: Ship windows, aircraft interior partitions

Technical Specifications: Laminated Glass Series

| Model | Composition | Total Thickness (mm) | Standard Size (mm) | Main Interlayer | Impact Resistance (J/m²) | Acoustic Reduction (dB) | Light Transmittance (%) |

|---|---|---|---|---|---|---|---|

| 5mm Laminated Glass | 2.2mm+0.76PVB+2.2mm | 5.16 | 1830×2440 | PVB | ≥ 1250 | 30~34 | 87.5 |

| 6.38mm Laminated Glass | 3mm+0.38/0.76PVB+3mm | 6.38/6.76 | 2440×3660 | PVB/EVA | ≥ 1530 | 34~37 | 85-87 |

| 8.76mm Laminated Glass | 4mm+0.76PVB+4mm | 8.76 | 3000×6000 | PVB | ≥ 1800 | 38~40 | 83-85 |

| 12mm Laminated Glass | 6mm+1.52PVB+6mm | 13.52 | 3660×4200 | PVB | ≥ 2300 | 40~44 | 80-82 |

Note: Data per ISO 12543, ASTM C1172:2019. Actual parameters may vary slightly by supplier/production line.

Technical Trends in Laminated Glass Manufacturing (2019–2024)

Data sources: Statista, VDMA GlassTech, Glass Magazine, China Glass Network.

Manufacturing Process: How Laminated Glass is Made

Precision cut to desired specs

→

🔓

Cleaning & InspectionAutomated washing, ISO 9001 quality checks

→

🧮

Interlayer PlacementPVB/EVA film laminated between glass

→

⚙️

Pre-Pressing (Roller/Autoclave)Remove air, bond layers

→

⚡

Final AutoclavingCuring at 135°C, 10-13 bar

→

🛠

Inspection & TestingISO/ANSI tests: impact, optical

→

✅

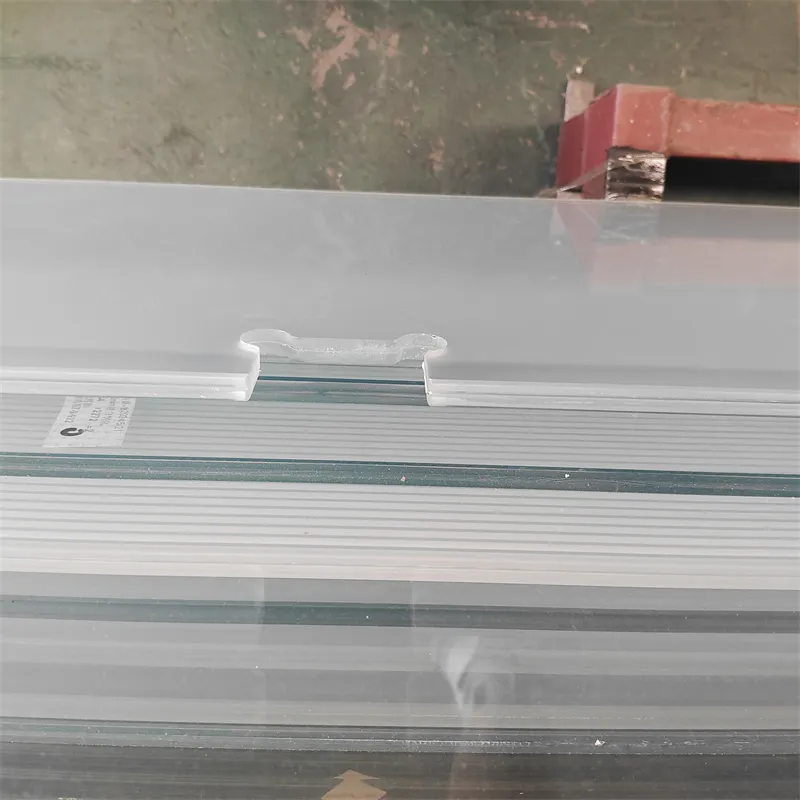

Packing & DeliveryProtective film, crating

See production video:

Watch: Industrial Laminated Glass Production

Material, Precision Craftsmanship & Standards

- Glass Type: Float, Low-E, Tempered

- Interlayer: PVB (standard), EVA (for UV/color/laminated glass art), SGP (SentryGlas® Plus) for max strength

- Manufacturing: Precision CNC edge processing, autoclave technology, ISO/ANSI calibration

- Certificates: ISO 12543, EN 14449, ANSI Z97.1, CCC (China), SGCC (US), CE Marking

- Typical Service Life: 20–35 years (per NFRC 2019 test reports)

By applying robust 13.52mm (12mm glass+1.52mm PVB) laminated structure, laminated glass doors and panels provide strength that far exceeds standard monolithic glass.

Product Comparison: Laminated Glass vs. Other Glass Solutions

| Index | Laminated Glass | Tempered Glass | Annealed Glass |

|---|---|---|---|

| Safety (Shatterproof) | High – remains integral | Breaks into granules | Shatters dangerously |

| Sound Insulation | Excellent (STC up to 42dB) | Moderate (STC 32dB) | Poor (STC 28dB) |

| UV Blocking | Up to 99% | ~40% | ~20% |

| Security/Forced Entry | Very High | Moderate | Low |

| Typical Applications | Facade, doors, banks, schools | Windows, balustrades | Low-use, low-risk |

| Regulatory Compliance | ANSI/EN/ISO, automotive, bulletproof | EN/ANSI glazing | Basic |

Application Segments (Global Laminated Glass Market, 2023)

Data: Statista 2024, Glassmagazine.com analytics

Key Application Cases: Real-World Experience

- High-rise curtain wall: Shanghai Tower, CN

Used 12mm laminated glass curtain walls for wind load, blast resistance, and thermal insulation. - Metro station platform barriers: Singapore MRT

8.76mm laminated glass for anti-vandal and safety protection, tested per EN 14449. - Banks / Secure facilities: PVB/SGP 20mm bulletproof laminated glass

- Residential skylights: 6.38mm laminated glass—superior UV & fall protection.

- Industrial process control rooms: Customized fire-resistant laminated glass for petrochemical operations.

Feedback: "Switching to laminated glass doors cut our noise level by 37%. Its impact tolerance is unmatched in our safety audits." — Project Manager, Global Construction Group

Major Brands & Supplier Comparison (Laminated Glass Door/Panels)

ChinaMirrorGlass

AGC

Saint-Gobain

Sisecam

CSG

When comparing suppliers, assess production standards, certifications, raw material control, post-sale service, and project portfolio. ChinaMirrorGlass delivers laminated glass solutions with full ISO 12543 / EN 14449 / CCC quality system, rapid customization, and global export.

Service since: 1998 | Exported to 110+ countries | Served Top 100 construction, rail & energy corporations.

Customization: Tailor-made Laminated Glass Solutions

- Thickness range: 4.38mm to 88mm (multi-layer bulletproof, soundproof design)

- Finish: Clear, ultra-clear, colored, printed, digital smart glass with switchable film

- Edge options: Polished, beveled, drill-holes, CNC cutting per CAD drawing

- Functionality: Fire-resistant, UV/IR blocking, privacy/smart tint, anti-slip

- Standards: Customizable to any regional building/fire code upon request

Delivery: Within 5–20 days based on order volume/complexity (average: 2,500 m2/day capacity—for 6.38mm laminated glass line).

Warranty: 10-15 years against delamination & yellowing (per EN 12543-2/ISO protocols)

Support: 24/7 technical hotline, onsite/offsite installation guidance.

Certifications: Full ISO/CE/CCC/EN/SGCC documentation provided.

Warranty: 10-15 years against delamination & yellowing (per EN 12543-2/ISO protocols)

Support: 24/7 technical hotline, onsite/offsite installation guidance.

Certifications: Full ISO/CE/CCC/EN/SGCC documentation provided.

Performance Index: Laminated Glass Types Analysis

Technical FAQ: Laminated Glass Industry Terminology

Q1. What is PVB and why is it used in laminated glass?

PVB (Polyvinyl Butyral) is the primary interlayer due to its superior adhesion, flexibility, and impact energy absorption. It keeps broken glass fragments together after impact, enhancing safety and security compliance per ISO 12543.

PVB (Polyvinyl Butyral) is the primary interlayer due to its superior adhesion, flexibility, and impact energy absorption. It keeps broken glass fragments together after impact, enhancing safety and security compliance per ISO 12543.

Q2. What are the main differences between 5mm, 6.38mm, and 12mm laminated glass?

Thickness impacts strength, soundproofing, and application: 5mm (lightweight, for windows), 6.38mm (standard façade/doors), 12mm+ (structural, anti-theft, bulletproof). Sound reduction, impact resistance, and price increase with thickness.

Thickness impacts strength, soundproofing, and application: 5mm (lightweight, for windows), 6.38mm (standard façade/doors), 12mm+ (structural, anti-theft, bulletproof). Sound reduction, impact resistance, and price increase with thickness.

Q3. Which certifications should laminated glass comply with?

Major standards: ISO 12543, EN 14449, ANSI Z97.1, SGCC, CCC, CE. Conformity ensures safety, UV filtering, optical quality, durability, and building code compliance globally.

Major standards: ISO 12543, EN 14449, ANSI Z97.1, SGCC, CCC, CE. Conformity ensures safety, UV filtering, optical quality, durability, and building code compliance globally.

Q4. What is the typical service life and maintenance needed?

Industry data shows a service life of 20–35 years in standard environments, with only standard cleaning required. De-lamination risk is minimized by advanced edge-seal technology.

Industry data shows a service life of 20–35 years in standard environments, with only standard cleaning required. De-lamination risk is minimized by advanced edge-seal technology.

Q5. Is laminated glass suitable for exterior (outdoor) use?

Yes. Thanks to UV/IR protective interlayer, weather-resistant bonding, and edge strengthening, laminated glass is widely used for outdoors, from balconies to skyscraper facades.

Yes. Thanks to UV/IR protective interlayer, weather-resistant bonding, and edge strengthening, laminated glass is widely used for outdoors, from balconies to skyscraper facades.

Q6. How is sound insulation measured in laminated glass?

Measured by the STC (Sound Transmission Class) value, determined per ASTM E413. Multiple interlayers boost acoustic performance (32–44dB typical range).

Measured by the STC (Sound Transmission Class) value, determined per ASTM E413. Multiple interlayers boost acoustic performance (32–44dB typical range).

Q7. Are custom shapes, CNC edges, and digital print finishes available?

Yes. With CNC machining, waterjet cutting, and digital ceramic printing, laminated glass can meet any architectural or industrial customization (size, color, graphics, drillings).

Yes. With CNC machining, waterjet cutting, and digital ceramic printing, laminated glass can meet any architectural or industrial customization (size, color, graphics, drillings).

References & Industry Insights

[1] Glass Magazine, "Laminated glass outlook for 2024".

[2] VDMA Glass Technology, "Global trends in architectural laminates", https://www.vdma.org/glass-technology

[3] "Laminated Glass: Standards & Design", glassonweb.com

[4] Statista, Laminated Glass Market Analysis

[5] "Best practice for laminated glass installation", Glass Bulletin 2023, glassonline.com

[2] VDMA Glass Technology, "Global trends in architectural laminates", https://www.vdma.org/glass-technology

[3] "Laminated Glass: Standards & Design", glassonweb.com

[4] Statista, Laminated Glass Market Analysis

[5] "Best practice for laminated glass installation", Glass Bulletin 2023, glassonline.com

Latest news

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS