Dec . 04, 2024 09:47 Back to list

china clear float glass

The Importance of China Clear Float Glass in Modern Manufacturing

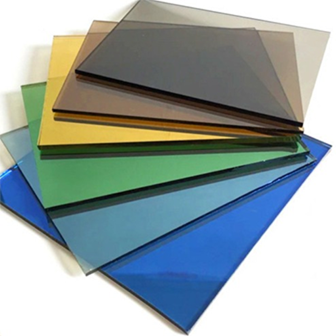

China has become one of the world leaders in the production of clear float glass, a key material widely used across various industries. This remarkable glass offers superior clarity, strength, and versatility, making it an essential component in construction, automotive, and even decorative applications. In this article, we will explore the characteristics of clear float glass, its manufacturing process, and the reasons behind its growing popularity, particularly in China.

What is Clear Float Glass?

Clear float glass is produced using a process that involves melting silica sand, soda lime, and other raw materials. The molten glass is then poured onto a bed of molten tin, where it floats and spreads out to form a flat, even surface. This unique manufacturing method gives clear float glass its characteristic smoothness and optical clarity. Unlike other types of glass, float glass has minimal distortion and can reach large dimensions, which makes it ideal for a variety of applications.

Characteristics of Clear Float Glass

One of the defining features of clear float glass is its high level of transparency. With a light transmittance of up to 90%, it allows maximum natural light, making it an excellent choice for buildings and homes where visibility and brightness are desired. The glass is also known for its durability and resistance to environmental factors. It can withstand certain levels of stress and pressure, making it suitable for both interior and exterior applications.

Additionally, float glass is customizable, as it can be easily cut, tempered, or coated to enhance its properties. For example, low-emissivity (Low-E) coatings can be applied to improve energy efficiency, reflecting heat back into the building while maintaining transparency. This adaptability has led to its increased use in energy-efficient constructions.

The Manufacturing Process

The manufacturing process of clear float glass in China involves several critical steps. First, high-quality raw materials such as silica sand, soda ash, and lime are sourced. These materials are then mixed in a furnace and heated to molten temperatures, typically above 1500°C (2732°F). Once the mixture is molten, it is carefully poured onto the surface of molten tin, where it spreads evenly.

china clear float glass

After cooling, the glass is cut into various sizes based on specifications. It may then undergo further processing, such as tempering, which involves reheating and rapidly cooling the glass to increase its strength. This process transforms it into tempered glass, which is used in applications such as shower doors, glass facades, and more.

Applications in Various Industries

The applications of clear float glass are vast and varied. In the construction industry, it is primarily used for windows, glass walls, and facades. Its aesthetics and strength make it a preferred choice for modern architectural designs. In the automotive sector, clear float glass is used for windshields and windows, where clarity and safety are paramount.

Moreover, the decorative glass market has embraced clear float glass for its versatility. It can be used in furniture designs, art pieces, and interior design elements. The ability to sandblast or frosted clear float glass adds an extra layer of customization, allowing artists and designers to experiment with textures and designs.

The Future of Clear Float Glass in China

As the demand for eco-friendly and energy-efficient materials grows, the clear float glass industry in China is expected to evolve and adapt. Innovations in production techniques and applications are on the horizon, with manufacturers exploring advanced coatings and composite materials that increase the performance of float glass.

Furthermore, as the global trend toward sustainable construction continues, clear float glass, particularly when treated for energy efficiency, will likely play a crucial role. China's commitment to green technologies positions its float glass industry well within this context, ensuring that it remains competitive in the global market.

In conclusion, clear float glass is a remarkable material that demonstrates both beauty and functionality. As China continues to lead in its production, the applications of this versatile glass are bound to grow, paving the way for innovative designs and sustainable building practices in the years to come.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS