Dec . 20, 2024 16:02 Back to list

cost of low iron glass

The Cost of Low Iron Glass An Overview

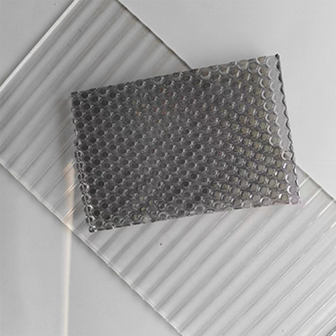

Low iron glass, often referred to as ultra-clear glass, has gained considerable attention in various industries, particularly in architecture, automotive, and electronics. Its unique properties, including high light transmission and minimal color distortion, make it an ideal choice for applications where clarity and aesthetics are paramount. However, like any specialized material, the cost of low iron glass can vary significantly depending on several factors, including production methods, thickness, and market demand.

Understanding Low Iron Glass

Low iron glass is produced with a reduction in the iron oxide content that is typically present in standard glass. This reduction results in a glass that exhibits remarkable transparency—up to 91% light transmission—allowing for more natural light penetration and improved visibility. The absence of greenish tint, which is common in regular glass due to iron impurities, is particularly appealing in applications such as display cases, skylights, and large façade installations.

The manufacturing process of low iron glass involves careful sourcing of raw materials and specialized production techniques. These methods tend to be more complex and costly than standard glass production, contributing to the overall price of the final product.

Factors Influencing the Cost

1. Raw Materials The composition of low iron glass requires higher quality raw materials than ordinary glass. The silica sand, for instance, must be of exceptional purity to minimize contamination. The costs of these high-grade materials inherently elevate the price of low iron glass.

cost of low iron glass

2. Production Process The manufacturing of low iron glass involves advanced techniques, such as floating and casting, which require precise control of temperature and atmosphere during production. These processes are energy-intensive and demand sophisticated technology, further adding to the cost.

3. Thickness and Size Thickness plays a critical role in determining the cost of low iron glass. Thicker panels, which are often required for structural applications, are more expensive due to the additional raw materials used and the altered production methods. Additionally, large sheets of low iron glass are more challenging to produce and transport, leading to higher costs.

4. Market Dynamics Like many commodities, the price of low iron glass is influenced by supply and demand factors. In periods of high demand, such as during urban development booms or renewable energy projects (e.g., solar panel manufacturing), prices may surge. Conversely, in times of market saturation, prices may stabilize or even decrease.

5. Customization Many projects require low iron glass to be cut, tempered, or coated to meet specific design or safety standards. These customizations can significantly increase the overall cost, but they also enhance the product's functionality and applicability for various uses.

Conclusion

The cost of low iron glass reflects its specialized nature and the advantages it provides over traditional glass. While the upfront investment may be higher, the long-term benefits, such as enhanced aesthetics, energy efficiency, and durability, can justify the expense. As technological advancements continue to evolve the production of low iron glass, it is likely that prices will adjust, potentially making this superior material more accessible to a broader range of applications. For architects, builders, and designers, understanding the cost dynamics of low iron glass is essential for making informed decisions in their projects, ensuring both performance and budget considerations are adeptly balanced.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS