Jan . 31, 2025 05:02 Back to list

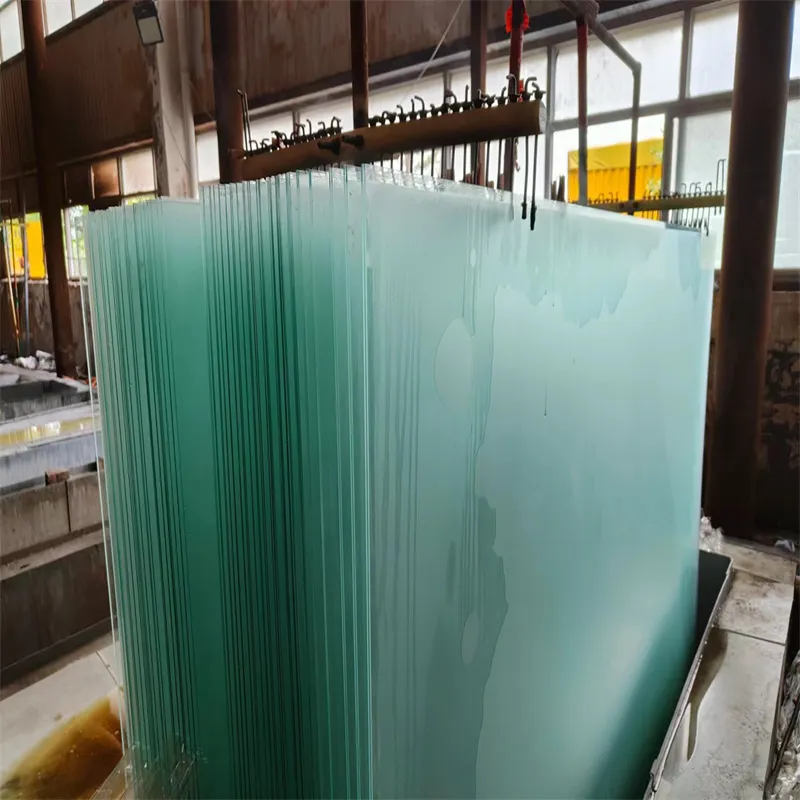

Float Glass

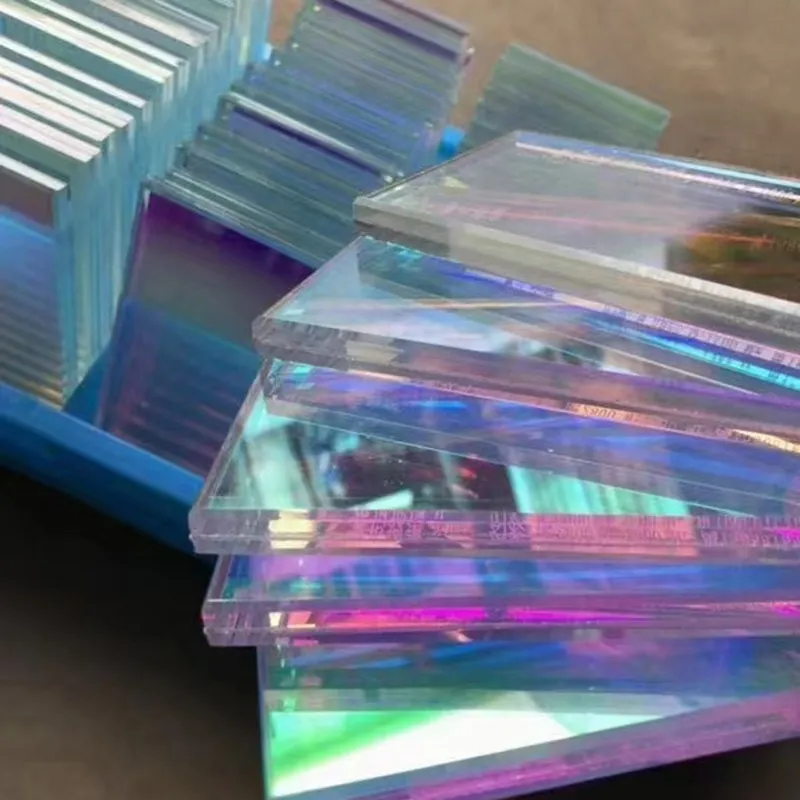

Curved safety glass has revolutionized various industries through its innovative design, providing not only aesthetic appeal but also enhanced safety and functionality. Born from advanced engineering techniques, curved safety glass is meticulously manufactured to offer optimal performance in demanding environments, making it an indispensable component in modern architecture and automotive design.

Trustworthiness in the use of curved safety glass is evident through consumer testimonials and case studies. Users consistently report satisfaction with its performance in weather resistance and thermal insulation, attributing their peace of mind to their choice of this high-performing material. In transportation sectors, studies illustrate a reduction in injury severity during accidents, attributed to the glass's ability to resist shattering into dangerous shards. Such anecdotal evidence, bolstered by empirical research, fosters trust among consumers and industry professionals alike. Further enhancing its appeal, the adaptability of curved safety glass allows for greater creativity in design without sacrificing safety. Architects and designers utilize its fluidity to craft seamless transitioning between indoor and outdoor spaces, contributing to open-concept environments that are both safe and inviting. Automobiles with aerodynamic designs benefit from the glass’s contour ability to minimize drag, improving fuel efficiency and adding a distinct characteristic to vehicle exteriors. Incorporating the latest innovations, curved safety glass also integrates smart technologies such as electrochromic layers, which enable the control of light penetration and enhance energy efficiency. These developments further cement its role as a forward-thinking solution that aligns with sustainable building practices. Industry leaders continuously explore these advancements, ensuring that their usage remains at the forefront of technology and consumer needs. In conclusion, curved safety glass stands out as an exemplar of modern material science that beautifully fuses form and function. Its proven durability, adaptability in design, and alignment with safety and environmental standards make it a premier choice across a multitude of applications. As industries continue to evolve, embracing such innovative products is essential in crafting future-ready structures and vehicles that prioritize both performance and protection.

Trustworthiness in the use of curved safety glass is evident through consumer testimonials and case studies. Users consistently report satisfaction with its performance in weather resistance and thermal insulation, attributing their peace of mind to their choice of this high-performing material. In transportation sectors, studies illustrate a reduction in injury severity during accidents, attributed to the glass's ability to resist shattering into dangerous shards. Such anecdotal evidence, bolstered by empirical research, fosters trust among consumers and industry professionals alike. Further enhancing its appeal, the adaptability of curved safety glass allows for greater creativity in design without sacrificing safety. Architects and designers utilize its fluidity to craft seamless transitioning between indoor and outdoor spaces, contributing to open-concept environments that are both safe and inviting. Automobiles with aerodynamic designs benefit from the glass’s contour ability to minimize drag, improving fuel efficiency and adding a distinct characteristic to vehicle exteriors. Incorporating the latest innovations, curved safety glass also integrates smart technologies such as electrochromic layers, which enable the control of light penetration and enhance energy efficiency. These developments further cement its role as a forward-thinking solution that aligns with sustainable building practices. Industry leaders continuously explore these advancements, ensuring that their usage remains at the forefront of technology and consumer needs. In conclusion, curved safety glass stands out as an exemplar of modern material science that beautifully fuses form and function. Its proven durability, adaptability in design, and alignment with safety and environmental standards make it a premier choice across a multitude of applications. As industries continue to evolve, embracing such innovative products is essential in crafting future-ready structures and vehicles that prioritize both performance and protection.

Next:

Latest news

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS