Dec . 04, 2024 09:45 Back to list

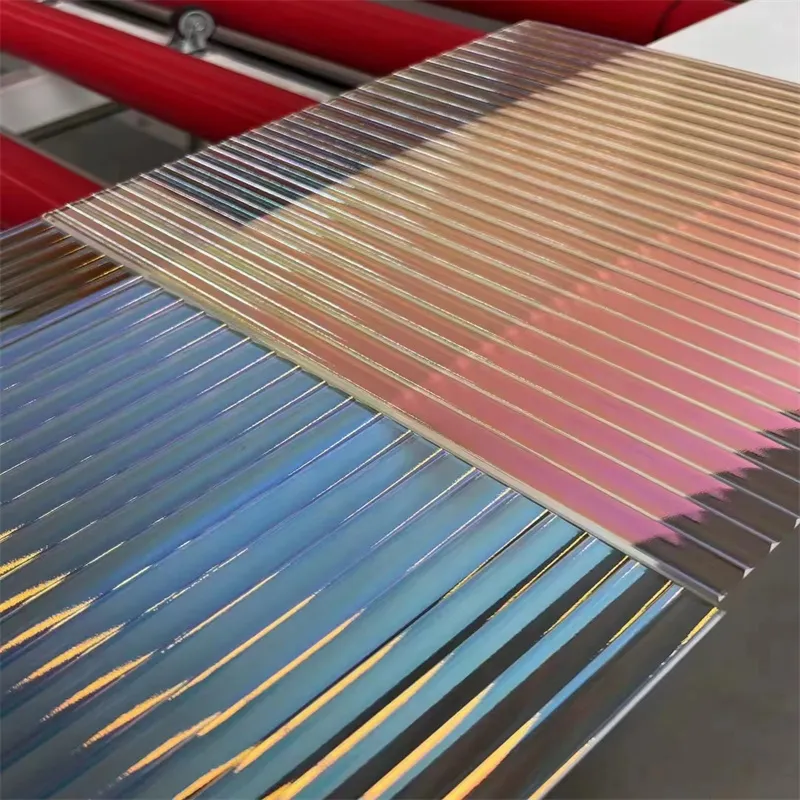

cutting toughened glass

Cutting Toughened Glass A Comprehensive Guide

Toughened glass, also known as tempered glass, is widely used in a variety of applications due to its superior strength, safety features, and aesthetic appeal. This type of glass is manufactured through a process of extreme heating and rapid cooling, which enhances its strength compared to regular glass. However, cutting toughened glass is a challenging task that requires special tools and techniques. In this article, we will explore the process, considerations, and best practices for cutting toughened glass.

Understanding Toughened Glass

Before delving into the cutting process, it's essential to understand why toughened glass is different from regular glass. Toughened glass is heated to about 620 degrees Celsius (1,148 degrees Fahrenheit) and then rapidly cooled. This unique treatment not only increases its impact resistance but also allows it to withstand thermal stress better than ordinary glass. Importantly, when broken, toughened glass shatters into small, blunt pieces that are less likely to cause injury, making it a preferred choice for safety applications.

Why Cutting Toughened Glass is Difficult

Unlike regular glass, which can be easily scored and snapped, toughened glass cannot be cut once it has been tempered. Attempting to do so without the right tools and techniques will likely result in chipping or shattering the entire sheet. Thus, if you need a specific dimension, it’s crucial to ensure accurate measurements before the toughening process begins.

Cutting Toughened Glass The Right Techniques

cutting toughened glass

1. Pre-Cutting Measurements The first step in working with toughened glass is to take accurate measurements. Ensure that the dimensions are precise, as any errors will require a complete re-manufacture of the glass. Use measuring tapes or laser measuring tools for accuracy.

2. Consulting Professionals Given the complexities involved in working with toughened glass, the best course of action is often to consult with professionals. Glass manufacturers can custom-fabricate pieces according to your specifications. They can also provide cutting services before the toughening process is completed.

3. Using Specialized Tools If you find yourself in a position where you need to make adjustments post-tempering, specialized cutting tools, such as diamond saws and waterjet cutters, can be employed. These tools are designed to handle the high-stress nature of tempered glass. However, these options are still recommendations for professionals in the industry rather than DIY tasks.

4. Avoiding Slicing Techniques Common techniques used for cutting regular glass, such as scoring and snapping or utilizing handheld glass cutters, should never be applied to toughened glass. Instead, focus on the right machinery, as improper techniques will damage the glass and compromise its integrity.

5. Edge Finishing In cases where you do have a leading edge but want to smooth it out, grinding machines specifically designed for glass can be utilized. Edges must be polished or ground to ensure that there are no sharp, hazardous fragments left.

Conclusion

In summary, cutting toughened glass requires a different approach compared to regular glass. With its enhanced strength and safety properties, it is vital to measure correctly and consult with professionals to avoid costly mistakes. When alterations are necessary, specialized tools and techniques are essential to achieve a satisfactory result without compromising the glass's integrity. Toughened glass finds its applications in a range of sectors, from automotive to architecture, and its benefits outweigh the challenges associated with cutting it. Always prioritize safety and consult with experts when working with this durable material to ensure optimal results.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS