Dec . 11, 2024 10:06 Back to list

Exploring Various Categories of Tempered Glass and Their Unique Applications

Different Types of Tempered Glass

Tempered glass, also known as toughened glass, is a type of safety glass that has been treated by controlled thermal processes to increase its strength compared to standard glass. This material is widely used in various architectural and automotive applications due to its ability to withstand high temperatures and impact. Understanding the different types of tempered glass can help you make informed decisions when specifying materials for your projects.

1. Clear Tempered Glass

Clear tempered glass is the most common type and is widely used in residential and commercial buildings. It allows for maximum light transmission while providing enhanced safety and thermal resistance. This type of glass is often utilized in windows, doors, and shower enclosures. The clarity of this glass makes it an excellent choice for applications where visibility and aesthetics are critical.

Low iron tempered glass, also referred to as ultra-clear glass, contains significantly less iron oxide than standard glass. This results in a glass with minimal green tint, making it a popular choice for high-end applications where clarity is paramount. It is often used in museums, aquariums, and display cases to showcase artworks or artifacts without distortion. Additionally, low iron tempered glass is highly durable and resistant to environmental factors.

3. Frosted Tempered Glass

Frosted tempered glass is created by sandblasting or acid etching the surface, which gives it a translucent appearance. This type of glass is favored for applications where privacy is essential, such as in bathroom windows, office partitions, and shower doors. The obscured view provided by frosted glass helps maintain privacy while still allowing natural light to filter through. Due to the tempering process, it retains strength and safety features that are beneficial in public and commercial spaces.

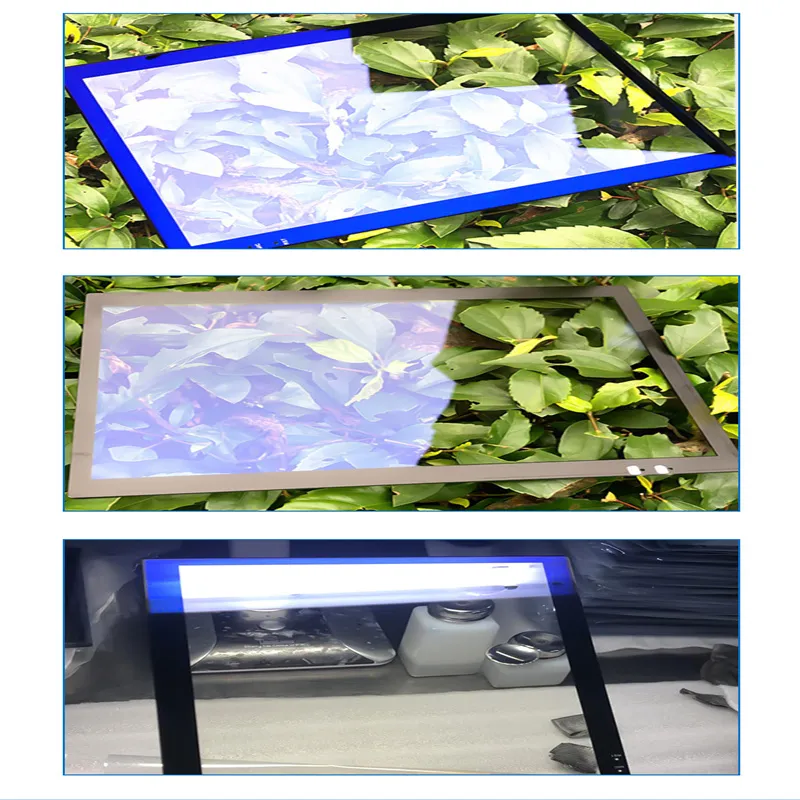

different types of tempered glass

4. Reflective Tempered Glass

Reflective tempered glass features a thin coating that reflects a portion of light, which can reduce solar heat gain and glare. This type is often used in modern building facades and commercial offices, contributing to energy efficiency and enhancing aesthetic appeal. Reflective glass comes in various colors and finishes, allowing architects and designers flexibility in creating visually appealing structures while promoting sustainability.

5. Ceramic Fritted Tempered Glass

Ceramic fritted tempered glass is coated with a ceramic paint that is baked into the surface during the tempering process. This type is particularly favored for building facades and skylights, as it provides both aesthetic value and functionality. The fritted coating can create patterns or serve as a solar control element, helping to improve thermal performance. Additionally, it offers enhanced durability against scratches and weathering, making it ideal for long-lasting applications.

6. Laminated Tempered Glass

Laminated tempered glass combines the benefits of both laminated and tempered glass. It consists of two or more layers of glass bonded together with an interlayer, which can help prevent shattering upon impact. This type is often used in safety-critical applications, such as in car windows and glass railings. The interlayer also provides added sound insulation and UV protection, enhancing the overall performance of the glass.

Conclusion

Tempered glass comes in various types, each suited for specific applications based on aesthetic, safety, and functional requirements. From clear and low iron options to frosted, reflective, ceramic fritted, and laminated varieties, the versatility of tempered glass makes it a desirable choice for architects, builders, and designers. When selecting the right type of tempered glass, it's important to consider factors such as strength, aesthetics, thermal performance, and application requirements to ensure you achieve the desired results in your project.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS