Nov . 16, 2024 20:51 Back to list

Innovative Applications and Benefits of Flat Float Glass in Modern Architecture

The Multifaceted World of Flat Float Glass

Flat float glass, a fundamental building material in modern architecture and design, plays an indispensable role in various applications ranging from windows to mirrors and glass facades. Its manufacturing process, unique properties, and array of uses underscore its significance in both residential and commercial sectors.

Manufacturing Process

The production of flat float glass is a meticulous process beginning with the melting of raw materials, primarily silica sand, soda ash, and limestone. Once these ingredients are heated to extremely high temperatures, they become molten glass. This molten glass is then poured onto a bed of molten tin, a critical element in the float glass process. The tin's density allows the glass to spread out and form a perfectly flat surface as it cools. This method yields a high-quality glass sheet with exceptional clarity and uniform thickness.

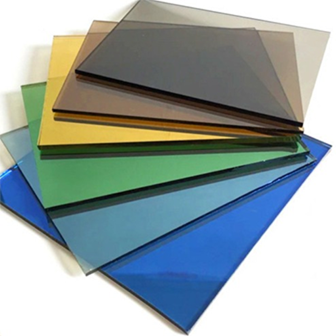

After the initial cooling phase, the glass is further processed to enhance its characteristics. It may be annealed, a heat treatment process that relieves internal stresses, ensuring durability. Moreover, the glass can undergo various treatments such as coating for UV protection or tinting for aesthetic appeal, leading to the diverse forms of flat float glass available on the market.

Characteristics

flat float glass

Flat float glass is celebrated for its remarkable transparency, optical clarity, and smooth surface finish. These attributes make it ideal for applications where vision and aesthetics are paramount. The smooth surface resists dirt accumulation, making maintenance easier, while its ability to withstand moderate impacts enhances safety and longevity. Additionally, innovations in glazing technologies have allowed for the development of energy-efficient variants, such as low-emissivity (Low-E) glass, which minimizes heat transfer, contributing to environmentally friendly building designs.

Applications

The versatility of flat float glass is evident in its wide array of applications. In residential buildings, it serves as a primary material for windows and doors, allowing natural light to flood indoor spaces while providing insulation and security. In commercial settings, flat glass plays a crucial role in creating stunning glass facades that not only enhance aesthetic appeal but also promote energy efficiency.

Moreover, flat float glass is widely used in furniture and interior design. From coffee tables to mirrors, its sleek and reflective surfaces add a contemporary touch to any space. In the automotive industry, flat glass is essential for windshields and windows, ensuring clarity and safety for drivers and passengers alike.

Conclusion

In conclusion, flat float glass stands out as a cornerstone of modern construction and design. Its unique manufacturing process and impressive characteristics make it a reliable choice for a myriad of applications. As technology continues to advance, we can expect to see even more innovative uses and enhancements for flat float glass, solidifying its position as an essential element in our everyday lives. Whether in the home or the office, flat float glass serves as a bridge between functionality and elegance, transforming spaces and enhancing our experiences.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS