Jan . 10, 2025 08:58 Back to list

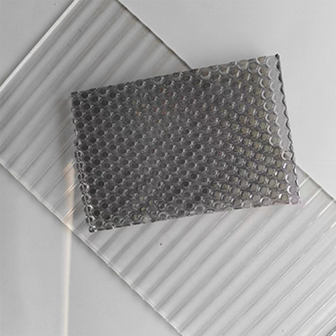

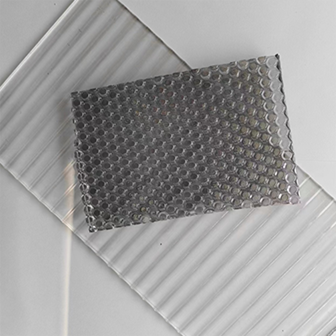

float annealed glass

Float annealed glass, known for its exceptional quality and versatility, stands as a cornerstone in the architectural and interior design industries. This glass variant is crafted through the advanced float process, which begins with the careful melting of raw materials like silica sand, soda ash, and limestone at approximately 1,700 degrees Celsius. Poured over a bed of molten tin, it achieves a flawlessly smooth surface free from distortions, thereby offering unparalleled clarity and uniformity. By undergoing a meticulous annealing process, the glass is gradually cooled to remove internal stresses, ensuring its durability and strength, making it an optimal choice for numerous applications.

From a consumer experience perspective, float annealed glass stands out for its cost-effectiveness compared to its tempered counterpart. Its extensive compatibility with cutting, drilling, and coating processes allows homeowners and businesses alike to procure customized solutions without incurring exorbitant costs. Such versatility simplifies installation and reduces labor expenses, contributing significantly to its popularity in budget-conscious projects. Moreover, its recyclability aligns with increasing consumer demand for sustainable building materials, ensuring that choosing float annealed glass supports environmentally responsible construction practices. In conclusion, float annealed glass embodies a fusion of technological prowess and practical applicability, rightfully positioning itself as a fundamental element in modern construction and design. Its seamless blend of clarity, adaptability, and reliability provide stakeholders with a product that not only meets but often exceeds their spatial, aesthetic, and environmental requirements. Whether enhancing the panache of a retail showroom or ensuring the sophisticated elegance of a luxury high-rise, float annealed glass continues to affirm its reputation as an indispensable asset in the architectural landscape. Through continued dedication to quality and innovation, this type of glass will undoubtedly maintain its essential role in spearheading the future of sustainable and aesthetically pleasing building solutions.

From a consumer experience perspective, float annealed glass stands out for its cost-effectiveness compared to its tempered counterpart. Its extensive compatibility with cutting, drilling, and coating processes allows homeowners and businesses alike to procure customized solutions without incurring exorbitant costs. Such versatility simplifies installation and reduces labor expenses, contributing significantly to its popularity in budget-conscious projects. Moreover, its recyclability aligns with increasing consumer demand for sustainable building materials, ensuring that choosing float annealed glass supports environmentally responsible construction practices. In conclusion, float annealed glass embodies a fusion of technological prowess and practical applicability, rightfully positioning itself as a fundamental element in modern construction and design. Its seamless blend of clarity, adaptability, and reliability provide stakeholders with a product that not only meets but often exceeds their spatial, aesthetic, and environmental requirements. Whether enhancing the panache of a retail showroom or ensuring the sophisticated elegance of a luxury high-rise, float annealed glass continues to affirm its reputation as an indispensable asset in the architectural landscape. Through continued dedication to quality and innovation, this type of glass will undoubtedly maintain its essential role in spearheading the future of sustainable and aesthetically pleasing building solutions.

Next:

Latest news

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS