Nov . 18, 2024 07:56 Back to list

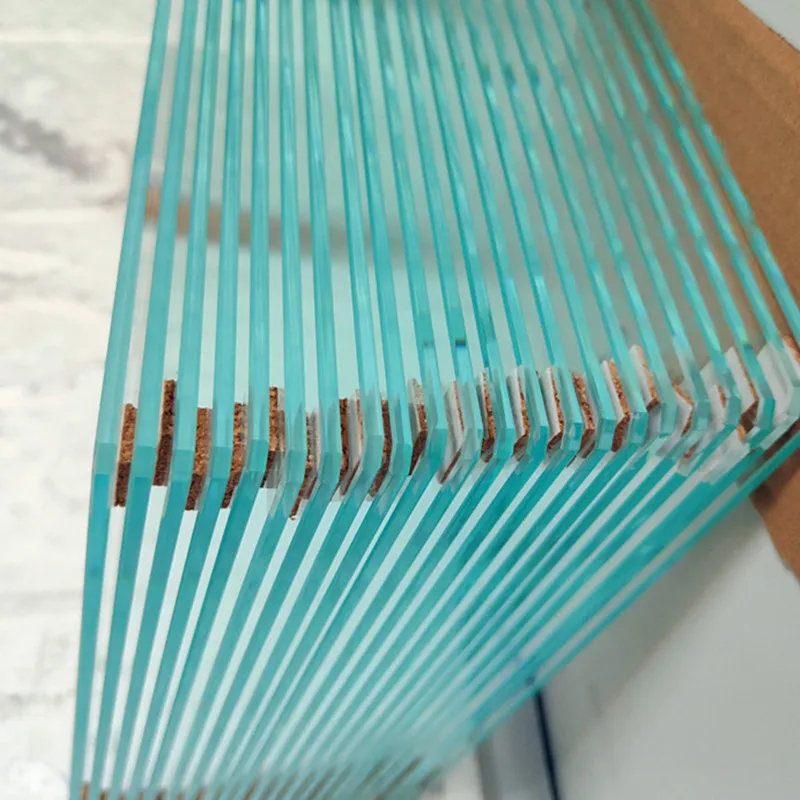

float glass cut to size

Understanding Float Glass Cut to Size

Float glass, a widely used type of glass, has revolutionized various industries with its unique properties and versatility. Made from high-quality silica, soda ash, and limestone, float glass is produced using the float process, a method that guarantees a smooth, flat surface. This article explores float glass cut to size, its applications, benefits, and its role in modern architecture and design.

What is Float Glass?

The float glass process involves melting raw materials to form molten glass, which is then floated on a bed of molten tin. This technique allows for the creation of extremely thin, perfectly flat sheets of glass without the distortions often found in other manufacturing methods. The result is a high-quality material that is crystal clear and of uniform thickness. Float glass can be tempered, laminated, or coated to enhance its properties, making it suitable for a multitude of applications.

Cutting Float Glass to Size

Cutting float glass to size is a critical process in various industries, from construction to automotive. This involves precise measurements and specialized tools to ensure accuracy. The cutting process can be done manually or with automated systems, depending on the size and complexity of the project.

1. Measurement and Planning Accurate measurements are crucial. Standard dimensions may not always fit the intended design, so custom sizing is often necessary. This requires careful planning and a clear understanding of the project's specifications.

2. Cutting Techniques There are several methods for cutting float glass, including scoring and snapping, water jet cutting, and CNC cutting. The choice of technique depends on the thickness of the glass, the complexity of the cuts, and the precision required.

3. Finishing Touches After cutting, the edges of the glass may require polishing or beveling to ensure safety and aesthetics. This step is essential, especially for applications where the edges will be exposed.

Applications of Cut-to-Size Float Glass

Float glass cut to size finds widespread application across various sectors

- Architecture In modern architectural design, large expanses of glass are often desired to create an open, airy feel. Custom-sized float glass windows, facades, and partitions are crucial for achieving this.

float glass cut to size

- Interior Design Custom mirrors, glass tables, and decorative partitions often require cut-to-size float glass. Designers can achieve tailored looks that fit the needs of a specific space.

- Automotive Industry The automotive sector utilizes float glass for windshields, windows, and mirrors

. The ability to cut glass to specific sizes is vital for ensuring safety and functionality in vehicles.- Furniture Upscale furniture pieces often incorporate glass elements. Whether it be shelves, tabletops, or doors, having glass cut to precise measurements is essential for functionality and design integrity.

Benefits of Float Glass Cut to Size

The primary benefits of using float glass cut to size include

- Customization The ability to have glass tailored to specific dimensions allows for greater creativity in design and functionality.

- Quality Float glass is known for its clarity and strength, ensuring durability for both structural and decorative applications.

- Versatility With the option to laminate or temper, cut-to-size float glass can be adapted for various needs, such as increased thermal insulation or safety.

- Cost-Effectiveness Custom cuts reduce waste, making it a more economical option in both residential and commercial projects.

Conclusion

Float glass cut to size plays a vital role in modern architecture, design, and various industrial applications. Its ability to be tailored to specific requirements without compromising quality makes it a preferred choice for professionals in multiple sectors. As design trends continue to evolve, the importance of customized float glass will only increase, solidifying its status as a fundamental material in contemporary construction and design. Whether in a high-rise building or a simple piece of furniture, cut-to-size float glass brings clarity, elegance, and functionality to every project.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS