Jan . 09, 2025 12:42 Back to list

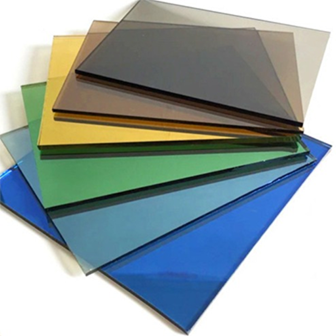

float glass for sale

Float glass, a cornerstone of modern architecture and design, is more than just a commodity; it is an innovation that has transformed the way we interact with space and light. Those in pursuit of superior-quality float glass for sale will find that understanding the intricacies of this material—and how it impacts both aesthetics and functionality—can significantly enhance decision-making and application outcomes.

Moreover, sourcing these products from reputable manufacturers who uphold rigorous quality standards and environmental protocols further accentuates trustworthiness in acquisitions. In my experience, companies that demonstrate transparency in their supply chain, from raw material sourcing to environmental impact disclosures, often produce float glass that not only meets but exceeds international safety and quality certifications. Investing in float glass brings an authentic and authoritative value to any project, demanding a thoughtful approach to supplier selection and material handling. Assessing elements like thermal insulation, light transmission rates, and the ability to customize coatings for energy efficiency can significantly elevate a building's performance and aesthetic appeal. Professionals seeking expertise in this domain should also consider collaborating with installers and architects familiar with cutting-edge trends and techniques to get the most operational and visual value from their float glass investments. Ultimately, the decision to purchase float glass should be informed by practical expertise, a deep understanding of the material’s inherent characteristics, and a commitment to sustainable and superior-quality practices. With its versatile applications and transformative influence on design aesthetics, float glass remains an integral choice for those aiming to craft innovative and functional spaces that stand the test of time. Therefore, whether you're an architect designing the next iconic skyscraper, a homeowner looking to enhance natural light within your space, or a tech company seeking clarity and precision in display technologies, selecting the right float glass is pivotal. Trust in expertise, prioritize sustainability, and make informed decisions to gain the utmost value in your endeavors with this unparalleled material.

Moreover, sourcing these products from reputable manufacturers who uphold rigorous quality standards and environmental protocols further accentuates trustworthiness in acquisitions. In my experience, companies that demonstrate transparency in their supply chain, from raw material sourcing to environmental impact disclosures, often produce float glass that not only meets but exceeds international safety and quality certifications. Investing in float glass brings an authentic and authoritative value to any project, demanding a thoughtful approach to supplier selection and material handling. Assessing elements like thermal insulation, light transmission rates, and the ability to customize coatings for energy efficiency can significantly elevate a building's performance and aesthetic appeal. Professionals seeking expertise in this domain should also consider collaborating with installers and architects familiar with cutting-edge trends and techniques to get the most operational and visual value from their float glass investments. Ultimately, the decision to purchase float glass should be informed by practical expertise, a deep understanding of the material’s inherent characteristics, and a commitment to sustainable and superior-quality practices. With its versatile applications and transformative influence on design aesthetics, float glass remains an integral choice for those aiming to craft innovative and functional spaces that stand the test of time. Therefore, whether you're an architect designing the next iconic skyscraper, a homeowner looking to enhance natural light within your space, or a tech company seeking clarity and precision in display technologies, selecting the right float glass is pivotal. Trust in expertise, prioritize sustainability, and make informed decisions to gain the utmost value in your endeavors with this unparalleled material.

Next:

Latest news

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS