Nov . 27, 2024 20:50 Back to list

Top Float Glass Manufacturers in the Industry Today

A Comprehensive Overview of Float Glass Manufacturers

Float glass, widely recognized for its superior quality and versatility, is an essential component in the construction and manufacturing industries. This glass type is produced through a process where molten glass is floated on top of molten tin, creating an incredibly flat and even surface. As the demand for float glass increases across various sectors, numerous manufacturers have emerged to meet this need.

The Float Glass Manufacturing Process

The float glass manufacturing process is a meticulous procedure that ensures the final product meets the highest standards of quality. Initially, raw materials like silica sand, soda ash, and limestone are melted in a furnace at high temperatures to form molten glass. The molten glass is then poured onto a bath of molten tin, where it spreads out evenly and forms a flat sheet as it cools.

One of the key advantages of this manufacturing method is the clarity and smoothness of the glass produced. The float glass process eliminates any surface imperfections, making it ideal for applications where transparency and aesthetics are paramount. After cooling, the glass is cut into sheets of varying sizes, which can then be treated or coated depending on their intended use.

Major Players in the Float Glass Industry

The float glass industry is characterized by a few major manufacturers that dominate the market. Some of these companies have established themselves as leaders due to their innovation, production capacity, and global reach.

1. Saint-Gobain Founded in 1665, Saint-Gobain is one of the oldest companies in the construction sector and a pioneer in glass manufacturing. Their float glass products are used extensively in architecture and automotive applications, emphasizing sustainability and energy efficiency.

2. Guardian Glass Guardian is a significant player in the float glass market, known for its commitment to technological advances and high-quality products. They offer a wide range of float glass options, including energy-efficient variants that help in reducing the environmental impact of buildings.

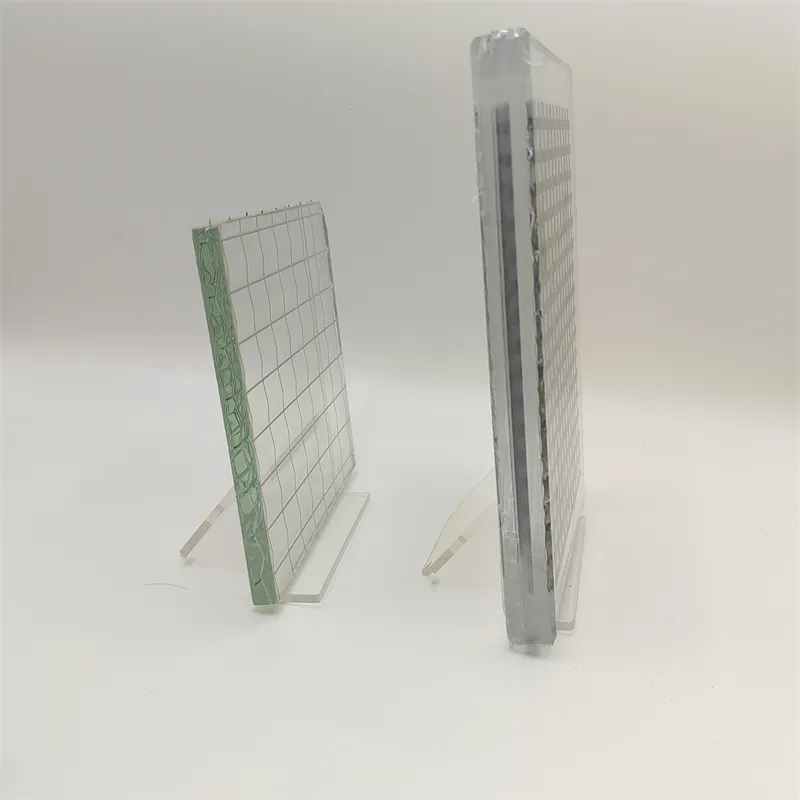

float glass manufacturers

3. AGC (Asahi Glass Company) Based in Japan, AGC is a leader in float glass production and is recognized for its R&D investments that lead to innovative glass solutions. The company focuses on developing high-performance glass for a variety of applications, including electronics and solar energy.

4. Pilkington Now part of NSG Group, Pilkington has a long-standing reputation in glass manufacturing. They are well-known for their float glass products that cater to both residential and commercial markets, with emphasis on durability and energy-saving features.

Emerging Trends in Float Glass Manufacturing

As the float glass industry evolves, several trends are reshaping the landscape. One significant trend is the increasing demand for energy-efficient and environmentally friendly glass products. Manufacturers are investing in technologies that allow for the production of low-emissivity (Low-E) coated glass, which helps to improve insulation in buildings and reduce energy consumption.

Another trend is the customization of float glass products to meet specific customer needs. Many manufacturers now offer a variety of finishes, colors, and thicknesses, ensuring that clients can find the perfect solutions for their projects.

Furthermore, advancements in digital technologies are revolutionizing the way float glass is produced and processed. Automation and smart technologies in manufacturing not only enhance efficiency but also improve the quality of the final product. For instance, companies are using AI and machine learning to monitor the quality of glass during production, identifying defects in real-time.

Conclusion

The float glass manufacturing industry plays a critical role in modern architecture and design, providing materials that are both functional and aesthetically pleasing. With a few dominant manufacturers leading the way and a shift towards sustainability and innovation, the industry is poised for continued growth. As the demand for high-quality float glass increases, manufacturers will need to adapt to changing market trends while maintaining their commitment to quality and sustainability. The future of float glass looks bright, with endless possibilities for innovation and improvement.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS