Jan . 14, 2025 10:03 Back to list

float glass manufacturing process

The float glass manufacturing process stands as a testament to modern engineering, contributing significantly to numerous industries with its remarkable adaptability and quality. Pioneered in the mid-20th century by Sir Alastair Pilkington, this process revolutionized glass production, creating a product that is both highly uniform and optically clear.

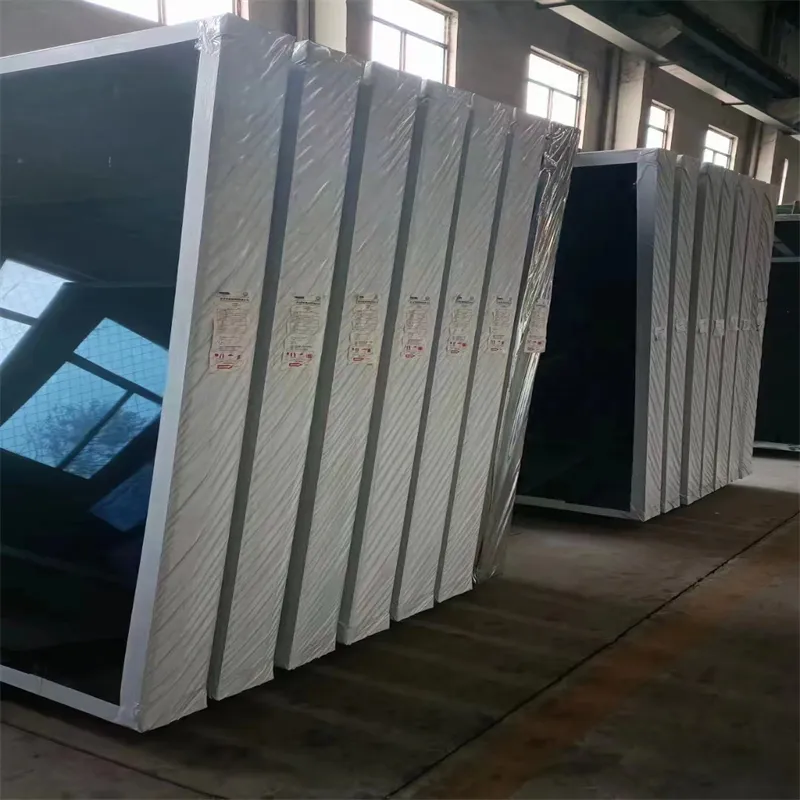

In advancing to the cutting and quality assurance stages, the float glass is examined for uniform thickness, clarity, and absence of impurities, features that authenticate its quality and trustworthiness. The precision of this step cannot be overstated; any deviation from the set standards can compromise the entire manufacturing batch. Automated systems and skilled technicians work in concert to ensure each piece of glass is cut to the specified dimensions, ready for distribution to various markets, including automotive, architectural, and solar energy sectors. In terms of environmental responsibility and sustainability—an aspect increasingly scrutinized—float glass manufacturing is evolving. Today's authoritative voice in the industry often discusses the advancements in recycling initiatives and emission reduction strategies. Residual glass from cutting and quality testing is often reclaimed and reintegrated into the initial melt, enhancing the eco-friendliness of the process. The implications of the float glass process extend into numerous applications, impacting everyday life and major industries alike. This manufacturing marvel exemplifies the pinnacle of Experience, Expertise, Authoritativeness, and Trustworthiness, ensuring float glass remains the industry standard for years to come.

In advancing to the cutting and quality assurance stages, the float glass is examined for uniform thickness, clarity, and absence of impurities, features that authenticate its quality and trustworthiness. The precision of this step cannot be overstated; any deviation from the set standards can compromise the entire manufacturing batch. Automated systems and skilled technicians work in concert to ensure each piece of glass is cut to the specified dimensions, ready for distribution to various markets, including automotive, architectural, and solar energy sectors. In terms of environmental responsibility and sustainability—an aspect increasingly scrutinized—float glass manufacturing is evolving. Today's authoritative voice in the industry often discusses the advancements in recycling initiatives and emission reduction strategies. Residual glass from cutting and quality testing is often reclaimed and reintegrated into the initial melt, enhancing the eco-friendliness of the process. The implications of the float glass process extend into numerous applications, impacting everyday life and major industries alike. This manufacturing marvel exemplifies the pinnacle of Experience, Expertise, Authoritativeness, and Trustworthiness, ensuring float glass remains the industry standard for years to come.

Latest news

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS