Jan . 13, 2025 15:10 Back to list

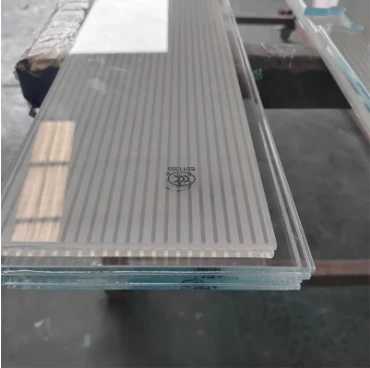

float glass sheet

Float glass, revered for its exceptional clarity and smooth surface finish, is a predominant product in the architectural and automotive industries. This ubiquitous material, known for its versatility and quality, breaks the barriers between the indoors and outdoors, allowing light to illuminate interiors and providing unimpeded views of the surroundings. Its production through the float process is an ingenious innovation that revolutionized glass manufacturing, distinguishing it from other types of glass.

Authoritativeness in the float glass industry is established by manufacturers who consistently adhere to high production standards and invest in research and development. Leading companies in the sector maintain rigorous quality control procedures to ensure that each sheet of float glass meets international safety and quality benchmarks. Professional associations and standards bodies, such as ASTM International and ISO, provide guidelines that further validate the credibility of float glass products in the market, reassuring consumers of their durability and performance. Trustworthiness in float glass products is engendered by the transparency of the manufacturing process and the traceability of materials used. Manufacturers who prioritize sustainability and safety by disclosing their methodologies foster consumer confidence. Educating consumers about the benefits and assurances provided by float glass, such as its recyclability and energy efficiency, strengthens the trust relationship. Testimonials from satisfied clients in the architectural and automotive domains further cement the reputation of float glass as a reliable material choice. In conclusion, float glass sheets are a cornerstone of modern architecture and design. Their unmatched clarity, durability, and adaptability confirm their status as a premium material choice. Whether enhancing the aesthetic appeal of a skyscraper or providing safety and efficiency in vehicles, float glass sheets stand as a testament to innovation and quality in glass manufacturing.

Authoritativeness in the float glass industry is established by manufacturers who consistently adhere to high production standards and invest in research and development. Leading companies in the sector maintain rigorous quality control procedures to ensure that each sheet of float glass meets international safety and quality benchmarks. Professional associations and standards bodies, such as ASTM International and ISO, provide guidelines that further validate the credibility of float glass products in the market, reassuring consumers of their durability and performance. Trustworthiness in float glass products is engendered by the transparency of the manufacturing process and the traceability of materials used. Manufacturers who prioritize sustainability and safety by disclosing their methodologies foster consumer confidence. Educating consumers about the benefits and assurances provided by float glass, such as its recyclability and energy efficiency, strengthens the trust relationship. Testimonials from satisfied clients in the architectural and automotive domains further cement the reputation of float glass as a reliable material choice. In conclusion, float glass sheets are a cornerstone of modern architecture and design. Their unmatched clarity, durability, and adaptability confirm their status as a premium material choice. Whether enhancing the aesthetic appeal of a skyscraper or providing safety and efficiency in vehicles, float glass sheets stand as a testament to innovation and quality in glass manufacturing.

Next:

Latest news

-

Sustainable Practices in a Modern Coated Glass Factory

NewsAug.07,2025

-

Insulated Glass Unit Installation Best Practices and Tips

NewsAug.07,2025

-

Frosted Glass Types and Custom Solutions for Sale

NewsAug.07,2025

-

Current Clear Float Glass Price Trends in Global Markets

NewsAug.07,2025

-

Comparing Different Types of Laminated Glass Performance

NewsAug.07,2025

-

Best Anti Fog Bathroom Mirror Solutions for Humid Climates

NewsAug.07,2025

Related PRODUCTS