Nov . 22, 2024 06:21 Back to list

glass toughened factory

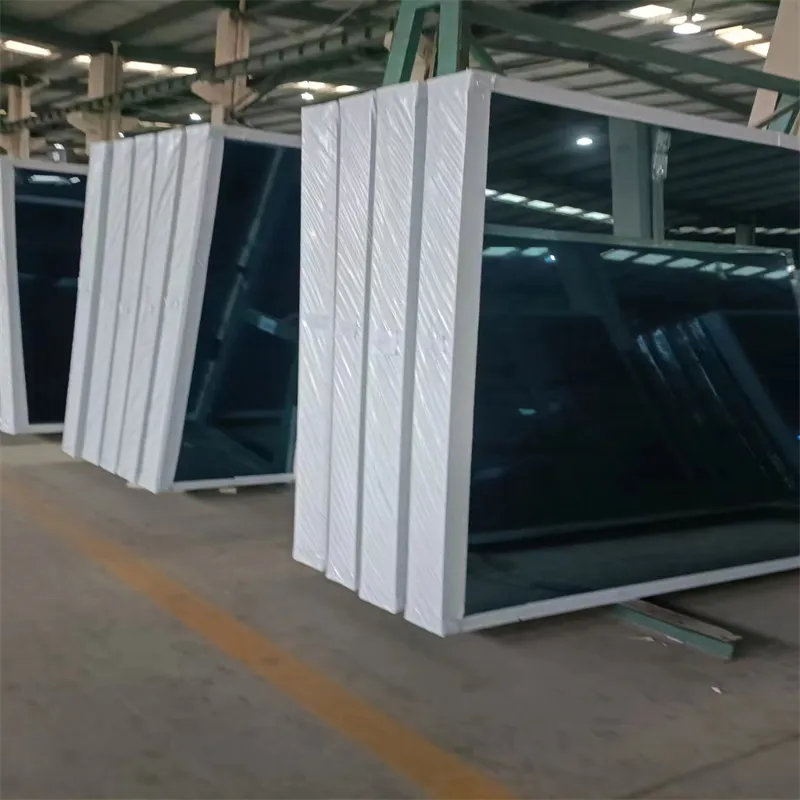

Glass Toughened Factory Innovating Safety and Durability

In recent years, the demand for toughened glass has soared due to its numerous advantages over traditional glass. As a material renowned for its strength, safety, and versatility, toughened glass has found applications across various industries, including construction, automotive, and interior design. A glass toughened factory plays a pivotal role in producing this innovative material, employing advanced technology to ensure both quality and safety.

Toughened glass is created through a process of extreme heating and rapid cooling, which significantly increases its strength compared to regular glass. This thermal treatment process allows the glass to withstand greater stress and impacts, making it an ideal choice for environments where safety is a priority. At a glass toughened factory, raw glass sheets are carefully inspected before being fed into furnaces that reach temperatures of over 600 degrees Celsius. Once heated, the glass is rapidly cooled, a process known as quenching, which toughens the material and helps to distribute internal stresses more evenly.

One of the key advantages of toughened glass produced in a dedicated factory is its safety feature. When broken, toughened glass shatters into small, blunt pieces rather than sharp shards, reducing the risk of injury. This characteristic makes it particularly suitable for use in public spaces, commercial buildings, and vehicles where safety regulations are stringent. The glass toughened factory therefore plays a crucial role in enhancing safety standards across different sectors.

glass toughened factory

In addition to its safety benefits, toughened glass also offers aesthetic appeal and versatility. It is available in various thicknesses and can be customized through different finishes, coatings, and tints. This adaptability allows architects and designers to innovate freely, creating breathtaking structures that utilize glass as a fundamental design element. For example, large glass facades can be seamlessly integrated into high-rise buildings, providing natural light while maintaining energy efficiency.

Environmental sustainability is another important aspect of modern glass toughened factories. With growing concerns about climate change and resource conservation, many factories are adopting eco-friendly practices. This includes the use of recycled materials and energy-efficient technologies, such as solar power and waste heat recovery systems. By minimizing their environmental footprint, glass toughened factories contribute to a more sustainable future while delivering high-quality products.

Moreover, the industry's focus on research and development ensures that new techniques and materials continue to emerge. The factory invests in skilled labor and advanced machinery, providing employees with training to improve efficiency and product quality. This commitment to innovation not only helps the factory to stay competitive but also meets the evolving needs of consumers in an ever-changing market.

In conclusion, a glass toughened factory serves as a hub of innovation and safety, producing a material that is essential in today’s world. By combining advanced technology, safety features, design flexibility, and sustainability, these factories are not only transforming the glass industry but also contributing to safer and more beautiful built environments. As demand for toughened glass continues to grow, these factories will play an increasingly vital role in shaping the future of construction and design.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS