Feb . 01, 2025 03:47 Back to list

toughened glass for sale

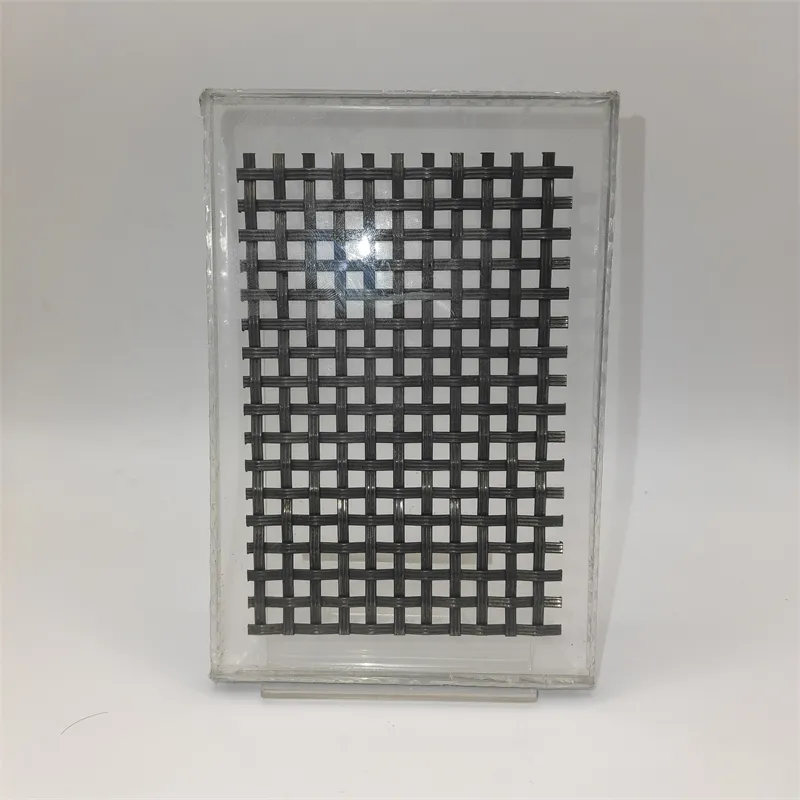

Laminated glass and toughened glass are often the subjects of choice when it comes to selecting the right glazing solution for a variety of applications. Understanding the unique properties and benefits of each can greatly impact the performance and safety of buildings and products. Both types of glass are integral components in our modern urban landscape, providing safety, security, and style.

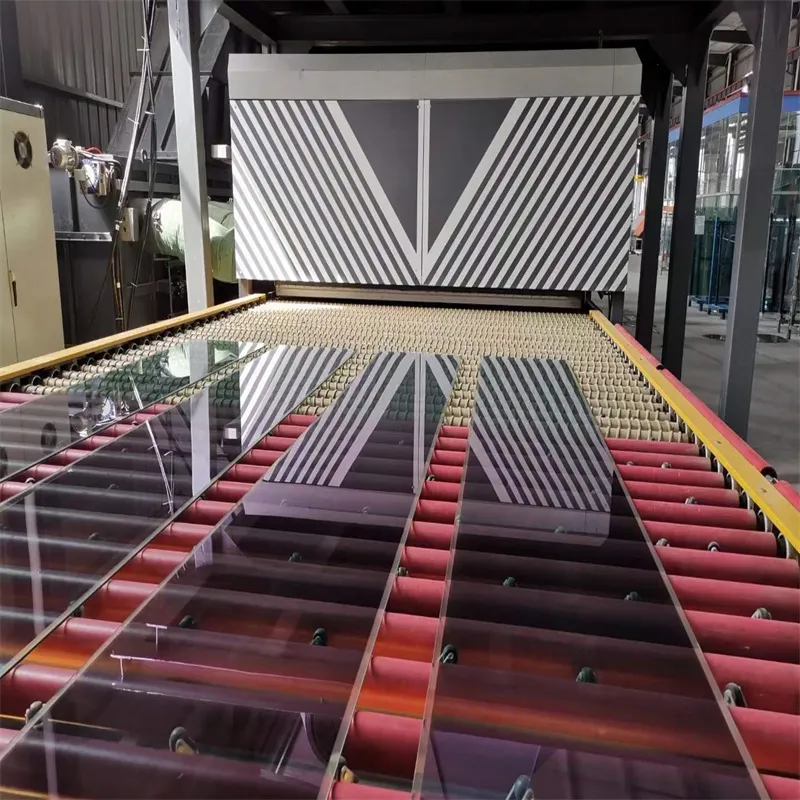

The thermal treatment process also endows toughened glass with increased resistance to thermal stress and temperature variations. This feature makes it invaluable in environments exposed to extreme heat or cold, such as exterior building glazing or glass coffee tables. Toughened glass can also be used in a variety of structural glazing applications, as it can withstand significant wind pressures and impacts, making it essential for high-rise buildings. When selecting between laminated and toughened glass, architects, builders, and designers should consider the specific requirements of the project. Laminated glass is preferable when sound attenuation, UV protection, and safety from shattering are paramount. On the other hand, for applications where high strength, impact resistance, and thermal safety are essential, toughened glass would be the material of choice. Both types of glass can also be combined to create a toughened laminated glass, offering both the safety features of laminated glass and the strength attributes of toughened glass. This combination is particularly useful in regions prone to hurricanes or in security-conscious buildings. In conclusion, both laminated and toughened glass offer unique benefits that can cater to a wide range of architectural applications. By understanding and leveraging the strengths of each type of glass, designers and builders can ensure both aesthetic appeal and functional performance, contributing to safer, more efficient, and more pleasing built environments.

The thermal treatment process also endows toughened glass with increased resistance to thermal stress and temperature variations. This feature makes it invaluable in environments exposed to extreme heat or cold, such as exterior building glazing or glass coffee tables. Toughened glass can also be used in a variety of structural glazing applications, as it can withstand significant wind pressures and impacts, making it essential for high-rise buildings. When selecting between laminated and toughened glass, architects, builders, and designers should consider the specific requirements of the project. Laminated glass is preferable when sound attenuation, UV protection, and safety from shattering are paramount. On the other hand, for applications where high strength, impact resistance, and thermal safety are essential, toughened glass would be the material of choice. Both types of glass can also be combined to create a toughened laminated glass, offering both the safety features of laminated glass and the strength attributes of toughened glass. This combination is particularly useful in regions prone to hurricanes or in security-conscious buildings. In conclusion, both laminated and toughened glass offer unique benefits that can cater to a wide range of architectural applications. By understanding and leveraging the strengths of each type of glass, designers and builders can ensure both aesthetic appeal and functional performance, contributing to safer, more efficient, and more pleasing built environments.

Next:

Latest news

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS