Dec . 19, 2024 06:19 Back to list

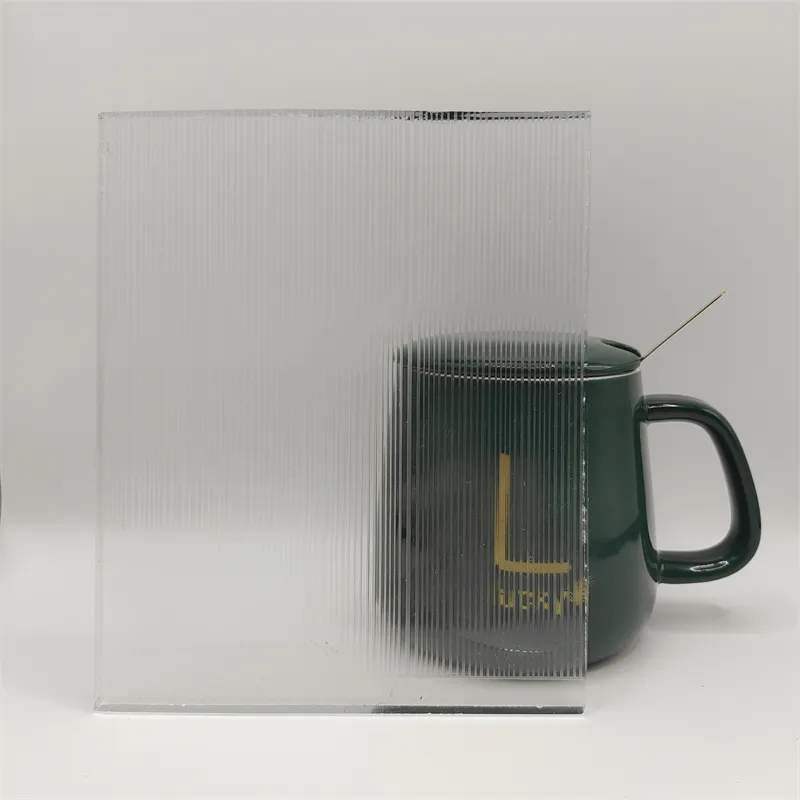

low iron glass cut to size

Understanding Low Iron Glass Cut to Size A Comprehensive Guide

Low iron glass, also known as low iron float glass, is an innovative construction material that has revolutionized the architectural and design sectors. Characterized by its high transparency and reduced greenish tint, low iron glass is often preferred for applications where clarity and aesthetics are paramount. This article explores the features, benefits, and applications of low iron glass cut to size, providing insights for architects, builders, and homeowners alike.

What is Low Iron Glass?

Low iron glass is made by reducing the iron content during the glass manufacturing process. Traditional glass contains a small amount of iron, which imparts a slight green hue. While this might be acceptable in many applications, it is less desirable in settings where clarity and color accuracy are crucial—such as in museum displays, high-end architecture, and modern interiors. Low iron glass offers optical clarity close to that of clear water, allowing for virtually distortion-free viewing.

Cutting Low Iron Glass to Size

One of the significant advantages of low iron glass is its ability to be cut to various sizes and shapes, allowing for flexibility in design. The cutting process involves precision tools and techniques to ensure clean edges and accurate dimensions. Here are some key considerations when cutting low iron glass

1. Measurement Accuracy Precise measurements are essential before cutting. Even a minor error can lead to a mismatch in installation or design aesthetics. Hence, professionals often use templates or digital measurement tools for accuracy.

2. Tools Required Specialized glass cutting tools, such as diamond-tipped cutters, are employed to achieve clean cuts. Additionally, proper safety equipment, including gloves and goggles, is essential to protect against glass shards.

3. Techniques The scoring and snapping technique is commonly used for glass cutting. After scoring the glass, it is carefully snapped along the score line. For more intricate designs, water jet cutting or laser cutting may be utilized, especially for thick panels.

4. Finishing After cutting, the edges of low iron glass often require polishing to eliminate sharp edges and ensure safety. This process enhances not only the look but also the durability of the glass.

Advantages of Low Iron Glass Cut to Size

low iron glass cut to size

2. Versatility It can be used in a variety of settings, including residential, commercial, and industrial applications. Whether for windows, partitions, or tabletops, low iron glass can be tailored to fit any design requirement.

3. Energy Efficiency Low iron glass can contribute to energy efficiency in buildings by allowing more natural light to penetrate while reducing glare. This helps to create brighter interiors, minimizing the need for artificial lighting during the day.

4. Durability Like traditional glass, low iron glass is strong and resistant to environmental factors. It can be tempered for added strength, making it suitable for various applications where safety is a concern.

Applications of Low Iron Glass Cut to Size

1. Architectural Design Modern buildings often utilize low iron glass in facades, skylights, and windows to enhance natural light and create sleek, contemporary designs.

2. Interior Design Low iron glass is widely used in furniture, such as tabletops and shelving, where clarity and class are essential.

3. Retail Displays High-end retail stores favor low iron glass for display cases to showcase products without color distortion, allowing for an optimal shopping experience.

4. Art and Museums Curators choose low iron glass for exhibits to provide clear views of art pieces without altering their colors.

Conclusion

Low iron glass cut to size is a versatile and aesthetically pleasing material that plays a crucial role in various industries. Its clarity, durability, and customizability make it an ideal choice for architects, designers, and builders looking to create functional, beautiful spaces. As technology advances, the possibilities for low iron glass applications will continue to grow, making it a staple in modern construction and design practices. Whether you’re considering low iron glass for a new building project or a home renovation, understanding its features and benefits will undoubtedly enhance your decision-making process.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS