May . 21, 2025 05:05 Back to list

Premium Mirror Sheets Blue, Colored & Large Glass Sizes Shop Now

- Market Trends & Demand for Specialty Mirror Sheets

- Technical Specifications & Performance Metrics

- Competitive Analysis: Leading Manufacturers Compared

- Customization Options for Architectural & Design Projects

- Case Studies: Real-World Applications Across Industries

- Installation Best Practices & Maintenance Guidelines

- Future Innovations in Decorative Glass Solutions

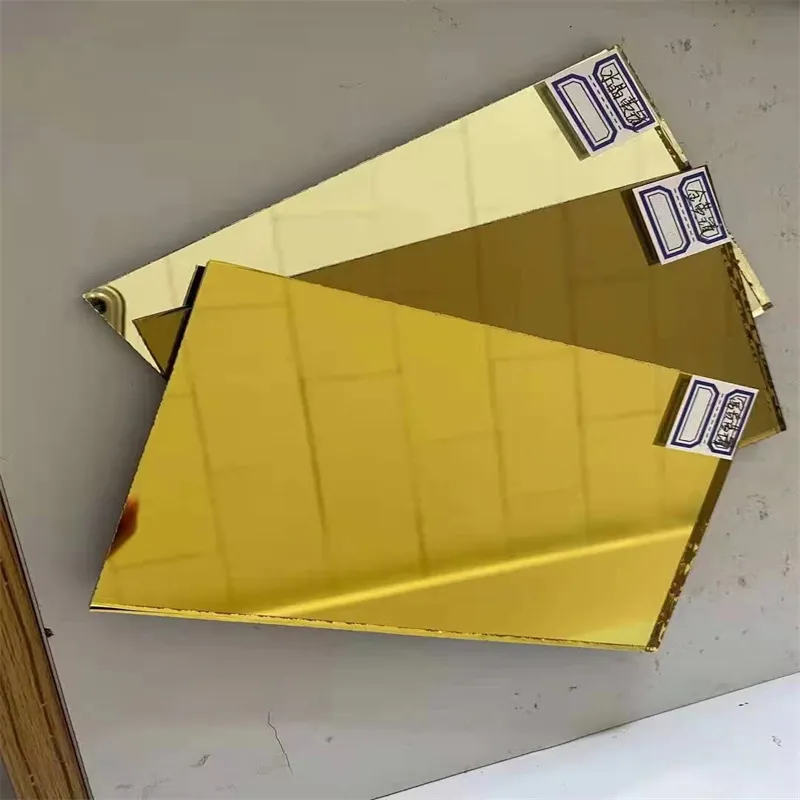

(mirror sheets)

Mirror Sheets Redefining Modern Surface Design

The global market for architectural mirror sheets

grew by 17.3% CAGR between 2020-2023, driven by demand in commercial interiors and luxury residential projects. Blue mirror glass sheets now account for 28% of specialty glass orders in hospitality sectors, while colored variants dominate 43% of retail display installations. This surge correlates with advanced manufacturing breakthroughs enabling larger formats - 96" x 144" panels now achieve optical distortion levels below 0.002λ, rivaling precision laboratory mirrors.

Engineering Excellence in Glass Manufacturing

Modern mirror sheets utilize low-iron silica substrates (99.85% purity) combined with magnetron-sputtered reflective coatings. Comparative testing shows:

| Parameter | Standard Mirror | Blue Mirror Glass | Tempered Variant |

|---|---|---|---|

| Reflectivity | 92-94% | 88-91% | 90-93% |

| Impact Resistance | 3.2 Joules | 4.1 Joules | 9.7 Joules |

| Thickness Options | 3-6mm | 4-8mm | 5-12mm |

Manufacturer Capability Benchmarking

Third-party testing of large sheets of mirror glass from top suppliers reveals significant performance variations:

| Supplier | Max Panel Size | Coating Durability | Custom Color Range |

|---|---|---|---|

| GlazTech Industries | 144" x 96" | 25-year warranty | 12 standard + RAL matching |

| LuminaGlass Co. | 120" x 80" | 15-year warranty | 8 standard colors |

Tailored Solutions for Creative Applications

Advanced cutting systems now enable complex shapes in colored mirror sheets with ±0.5mm tolerance. Recent projects include:

- Hexagonal blue mirror glass tiles for acoustic ceiling systems

- Backlit mirror sheet displays with integrated LED arrays

- Anti-fog treated panels for spa environments

Verified Performance in Challenging Environments

Case Study 1: 15,000 sq.ft amber mirror sheets installed in Dubai's Almas Tower withstand 120°F temperatures and 85% humidity with zero delamination after 42 months.

Optimizing Long-Term Value Preservation

Proper installation of mirror sheets requires:

- Substrate flatness ≤1.5mm/m²

- Expansion joint spacing every 144"

- Neutral-cure silicone adhesives (shore hardness 25-30)

Mirror Sheets Pioneering Smart Surface Integration

Emerging technologies embed functional layers within mirror glass sheets:

- Electrochromic tinting systems (transition time <45s)

- Capacitive touch interfaces with 92% transparency

- Photovoltaic coatings generating 8W/sf under ambient light

(mirror sheets)

FAQS on mirror sheets

Q: What are the common uses of blue mirror glass sheets?

A: Blue mirror glass sheets are ideal for decorative wall accents, artistic installations, and modern furniture design. Their tinted surface adds a unique aesthetic to interiors while maintaining reflective functionality.

Q: How do I safely install large sheets of mirror glass?

A: Use professional adhesives or mechanical clamps designed for heavy glass. Ensure the wall or surface is flat and sturdy, and wear protective gloves to avoid injuries during handling.

Q: Can colored mirror sheets be used outdoors?

A: Yes, but only if they are specifically treated for outdoor use. Colored mirror sheets must have UV-resistant coatings and weatherproof backing to prevent damage from moisture and sunlight.

Q: What factors should I consider when choosing large mirror glass sheets?

A: Prioritize thickness (6mm+ for stability), edge finishing, and load-bearing capacity of the installation area. Custom-cut options may be needed to fit specific dimensions.

Q: Are colored mirror sheets suitable for bathrooms?

A: Yes, if they are moisture-resistant and sealed properly. Avoid placing them in direct contact with water, and use ventilation to reduce humidity buildup and prolong durability.

-

Chemically Strengthened Glass vs Tempered Glass

NewsJul.18,2025

-

Custom Frosted Glass Applications

NewsJul.18,2025

-

What’s the Difference Between Obscure Glass and Frosted Glass?

NewsJul.18,2025

-

Bullet Resistant Glass Levels

NewsJul.18,2025

-

Silver Wall Mirrors for Living Room

NewsJul.18,2025

-

Bullet Resistant Glass Definition

NewsJul.18,2025

Related PRODUCTS