Nov . 17, 2024 11:42 Back to list

Reflective Splitting Techniques for Enhanced Precision and Efficiency in Cutting Processes

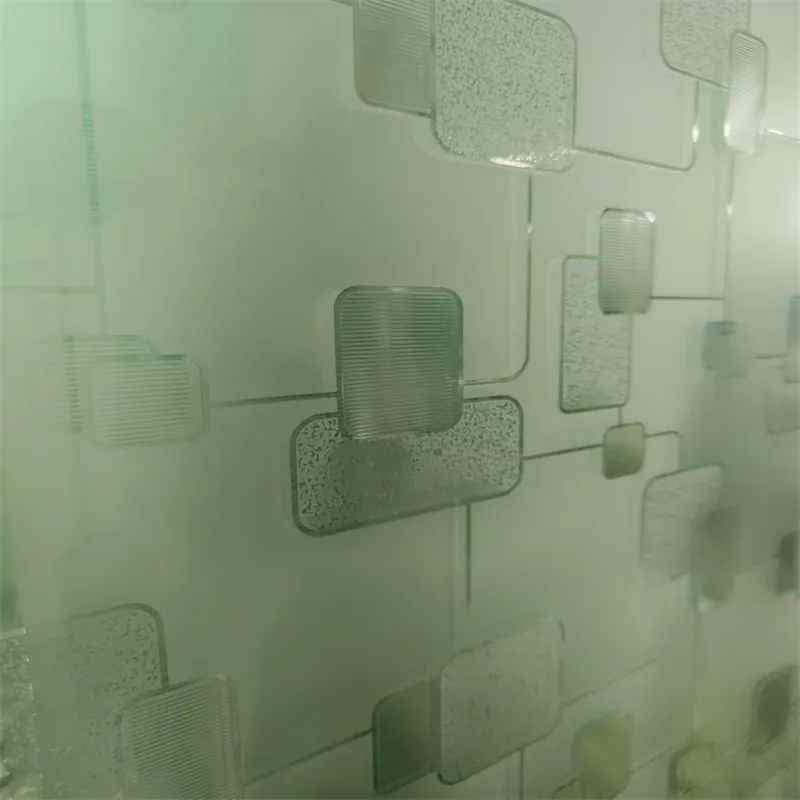

Exploring the Art of Mirror Cutting

Mirror cutting is an intricate and fascinating process that combines the precision of craftsmanship with the creativity of design. Originating in ancient civilizations, this technique has evolved over the years, resulting in a unique art form that captivates both artists and audiences alike. The allure of mirror cutting lies not just in its aesthetic appeal but also in the myriad of applications it finds in modern design and architecture.

At its core, mirror cutting involves shaping and finishing glass to create reflective surfaces, often used in decorative items, functional pieces, and architectural installations. The process begins with selecting the right type of glass. High-quality mirror glass is crucial as it ensures clarity, durability, and a flawless finish. The initial step in mirror cutting is to score the glass with a diamond-tipped cutter, creating a line that guides the break. This requires a steady hand and an eye for detail, as any miscalculation could lead to unsatisfactory results.

Once the glass is scored, the artist carefully snaps it along the line. After this, the edges are ground to smooth out any roughness, which not only improves the safety of the piece but also enhances its aesthetic appeal. Each piece can then be further manipulated by polishing, etching, or even layering with different materials that complement the reflective quality.

The design possibilities with mirror cutting are vast. Artists can create geometric patterns, intricate motifs, or even large-scale installations that transform spaces. For instance, in contemporary interior design, mirrors are often used to give the illusion of more space or to reflect light, making rooms appear brighter and more inviting. Mirror cutting allows designers to experiment with shapes and sizes, creating bespoke pieces that fit the specific needs of a project.

mirror cutting

Besides interior design, mirror cutting plays a significant role in art installations. Many contemporary artists utilize mirrors to explore themes of perception and reflection. By placing mirrors at various angles, they challenge the viewer’s understanding of space and their own image, often prompting a deeper contemplation of identity and existence. This interplay between reflection and reality can lead to transformative experiences for the audience.

In addition to its artistic applications, mirror cutting also serves functional purposes. Mirrors are essential components in essential items like vanity mirrors, bathroom fixtures, and even vehicles. The process of creating these functional objects still requires the same level of precision and artistry as creating decorative pieces. As technology advances, the methods for mirror cutting have also evolved, incorporating computer-controlled machinery that increases accuracy and allows for more complex designs.

The resurgence of interest in handcrafted items has led to a renewed appreciation for the art of mirror cutting. Artisans are now using traditional techniques to create unique pieces that stand out in a market flooded with mass-produced goods. This blend of tradition and innovation is helping to preserve the craft while allowing it to evolve to meet contemporary tastes.

In conclusion, mirror cutting is a multifaceted art form that bridges the worlds of craftsmanship and creativity. With its rich history and vast potential for modern applications, it continues to inspire artists and designers across various fields. As we appreciate the beauty of a well-crafted mirror piece, we also celebrate the skill and dedication that goes into its creation, ensuring that this art form remains valued for generations to come.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS