Dec . 09, 2024 18:37 Back to list

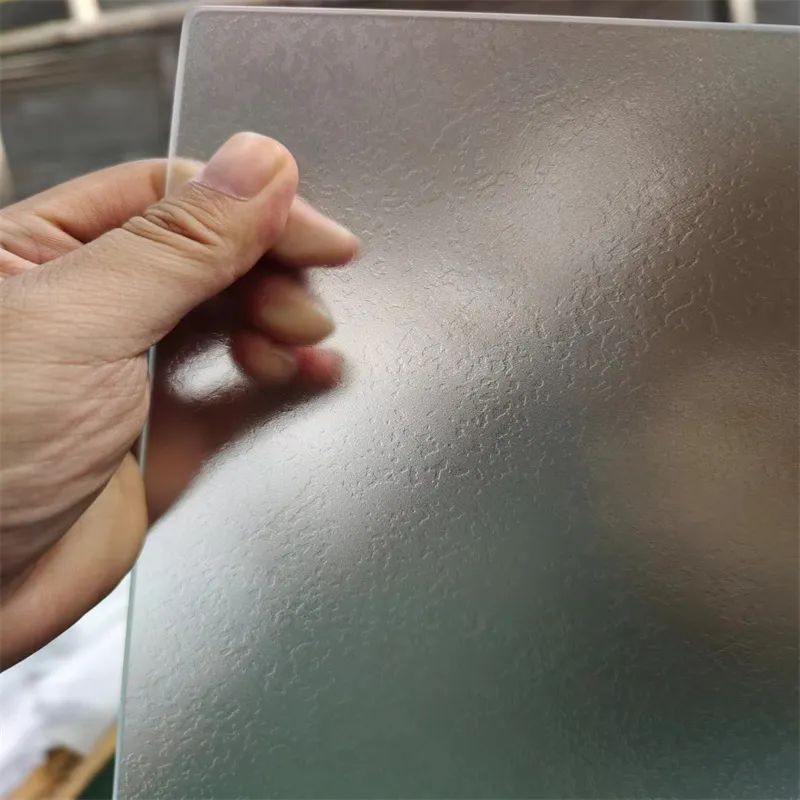

Customized High-Quality Tempered Glass Solutions for Various Applications and Industries

Understanding OEM Tempered Glass Benefits and Applications

In the world of manufacturing and construction, safety and durability are paramount. One material that has emerged as a front runner in providing both is tempered glass, particularly in the context of Original Equipment Manufacturer (OEM) solutions. This article aims to delve into the significance of OEM tempered glass, its benefits, and its applications across various industries.

What is Tempered Glass?

Tempered glass, also known as toughened glass, is a type of safety glass that has been treated by controlled thermal or chemical processes to increase its strength compared to normal glass. The manufacturing process involves heating the glass to a high temperature and then rapidly cooling it. This method induces compressive stresses on the surface of the glass, making it much tougher and more resistant to impact, thermal stress, and breakage.

The Role of OEM in the Glass Industry

Original Equipment Manufacturers, abbreviated as OEMs, are companies that produce parts and equipment that may be marketed by another manufacturer. In the context of tempered glass, OEMs are responsible for supplying customized glass solutions that meet the specific requirements of various industries, such as automotive, architecture, and electronics.

Advantages of OEM Tempered Glass

1. Enhanced Safety One of the primary benefits of tempered glass is its safety features. When shattered, it breaks into small, blunt pieces rather than sharp shards, significantly reducing the risk of injury. For industries where safety is a critical concern—like automotive and construction—OEM tempered glass is a preferred choice.

2. Durability and Strength OEM tempered glass is designed to withstand high levels of pressure and temperature variations. This enhanced durability makes it suitable for applications in extreme environments, such as offshore platforms, industrial facilities, and even high-rise buildings.

3. Customization OEMs offer a wide range of customization options for tempered glass. Clients can specify dimensions, thickness, tints, and coatings, ensuring that the final product perfectly matches their needs. This level of customization is particularly valuable in sectors like automotive, where the glass needs to fit specific models and designs.

oem tempered glass

4. Energy Efficiency Many OEM tempered glass products come with low-emissivity coatings, which help to reflect heat and UV rays. This property enhances energy efficiency in buildings and vehicles by reducing the need for air conditioning and heating, leading to lower energy bills and a reduced carbon footprint.

5. Aesthetic Appeal Besides functional benefits, OEM tempered glass can enhance the aesthetic appeal of structures and products. Available in various finishes and tints, it can add a modern touch to buildings, furniture, or automotive designs.

Applications of OEM Tempered Glass

The versatility of OEM tempered glass allows it to be utilized in a myriad of applications across different industries

- Automotive Industry OEM tempered glass is used in car windows and sunroofs. Its high strength and safety features make it an excellent choice for vehicle manufacturers focused on passenger safety.

- Architecture and Construction In buildings, tempered glass is commonly used in facades, doors, and windows. Its ability to withstand harsh weather conditions and provide thermal insulation makes it ideal for modern architecture.

- Electronics Tempered glass is increasingly popular in smartphone screens and other electronic devices due to its scratch resistance and durability.

- Furniture Design Many furniture items utilize tempered glass, such as tabletops and shelves, combining style with robust performance.

Conclusion

OEM tempered glass is an indispensable material that combines safety, strength, and aesthetic appeal across various industries. Its tailored solutions offered by OEMs cater directly to the diverse needs of manufacturers and consumers alike. As industries continue to innovate and prioritize safety and efficiency, the demand for high-quality tempered glass solutions will undoubtedly grow, cementing its role as a key player in modern manufacturing and construction. Whether you're an architect, automotive designer, or involved in electronics, understanding the benefits and applications of OEM tempered glass can provide significant advantages in your projects.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS