Nov . 12, 2024 05:55 Back to list

oem tempered glass

The Evolution and Significance of OEM Tempered Glass

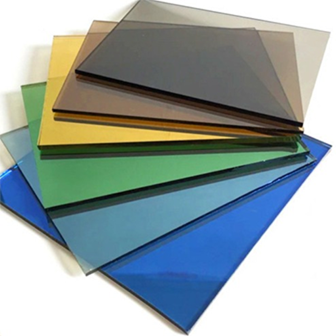

In today's world, the demand for high-quality glass products is on the rise, driven by industries such as construction, automotive, and electronics. Among the various types of glass available, OEM (Original Equipment Manufacturer) tempered glass stands out for its safety, durability, and versatility. In this article, we will explore the characteristics, manufacturing process, applications, and advantages of OEM tempered glass, shedding light on why it has become an essential component in modern manufacturing.

What is OEM Tempered Glass?

OEM tempered glass is a type of safety glass that has been heat-treated to increase its strength compared to standard glass. The term tempered refers to the process of heating the glass to a specific temperature and then cooling it rapidly, a method known as quenching. This alteration in the molecular structure of the glass enhances its resistance to impact and thermal stress, making it an ideal choice for a variety of applications.

The OEM designation indicates that the glass is made specifically for original equipment manufacturers who incorporate it into their products. This customization ensures that the glass meets particular specifications and quality standards set by the clients. Whether it's for an automobile window, a building facade, or electronic device screens, OEM tempered glass is tailored to fit the precise requirements, which adds significant value to the end product.

The Manufacturing Process

The manufacturing process of OEM tempered glass involves several critical steps. Initially, high-quality annealed glass is cut to the desired size and shape. After cutting, the glass undergoes a thorough cleaning process to eliminate any impurities or residues.

Once cleaned, the glass is heated in a furnace to temperatures ranging between 600 to 700 degrees Celsius. This heating process softens the glass, allowing it to be reshaped if needed. Following the heating, the glass is rapidly cooled through a controlled quenching process. This rapid temperature change is what imparts the additional strength to the glass, creating a surface compression that significantly enhances its durability.

After the tempering process, the glass can be subjected to various post-processing treatments, such as coating or laminating, to further enhance its performance characteristics based on the intended application.

Applications of OEM Tempered Glass

OEM tempered glass serves a multitude of applications across different industries

1. Architectural Applications It is commonly used in building facades, windows, and doors owing to its strength and safety features. In cases of breakage, tempered glass shatters into small, blunt pieces, reducing the risk of injury.

oem tempered glass

2. Automotive Industry OEM tempered glass is used for side windows and rear screens in vehicles. The enhanced strength provides safety during accidents and impacts, making it a preferred choice for car manufacturers.

3. Electronics With the rise of smart devices, tempered glass is often used as screens for smartphones, tablets, and monitors. Its scratch-resistant properties ensure longevity and a clear view.

4. Furniture Many modern furniture pieces utilize tempered glass for tables, shelves, and display cases, appreciating its aesthetic appeal combined with structural integrity.

Advantages of OEM Tempered Glass

The benefits of using OEM tempered glass are manifold

1. Safety The primary advantage is enhanced safety. In the event of breakage, it shatters into small, less harmful pieces, minimizing the risk of injuries.

2. Durability Tempered glass is up to five times stronger than regular glass, providing high resistance against impact and thermal stress.

3. Customization Being manufactured for specific clients allows for customization in sizes, shapes, and specifications, tailoring the product to meet exact needs.

4. Aesthetic Appeal OEM tempered glass can be treated or coated for aesthetic finishes, making it a popular choice for designers and architects looking for both functionality and style.

Conclusion

In summary, OEM tempered glass is a vital material that has transformed industries with its unique properties and design flexibility. As technology and design continue to evolve, the role of OEM tempered glass will likely expand further, cementing its place as a cornerstone of safety and innovation in manufacturing. Whether it’s enhancing our living spaces, increasing safety in vehicles, or providing a robust protection for our cherished devices, OEM tempered glass is indeed an unsung hero of modern material science.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS