Nov . 25, 2024 02:06 Back to list

Leading Manufacturers of High-Quality Plate Glass for Various Applications

The Plate Glass Manufacturing Industry An Overview

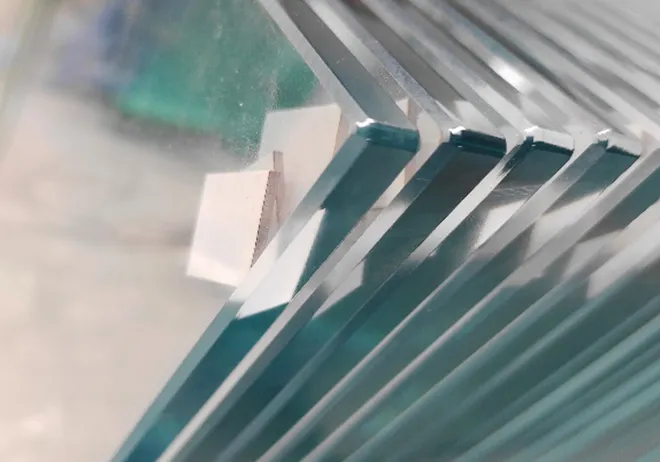

Plate glass, celebrated for its clarity and smooth finish, has been a vital material in various industries, from construction to automotive. This article aims to provide an insightful overview of the plate glass manufacturing industry, exploring its processes, challenges, and future prospects.

Understanding Plate Glass

Plate glass refers to flat glass that has been produced by various processes, primarily casting or float processes. The primary characteristics that distinguish plate glass from ordinary glass include its thickness, smooth surface, and transparency. Common applications of plate glass include windows, doors, display cases, and facades in commercial buildings, making it an essential material in modern architecture.

Manufacturing Processes

The production of plate glass typically involves two main techniques the polishing plate method and the float glass process

.1. Polishing Plate Method This traditional technique involves pouring molten glass onto a flat surface where it is allowed to cool and solidify. Once cooled, the glass is polished using grinding wheels to achieve a smooth finish. While this method can produce high-quality glass, it is less commonly used today due to its time-consuming nature and increased labor costs.

2. Float Glass Process The float glass method, developed in the 1950s, revolutionized the plate glass industry. In this process, molten glass is floated on a bed of molten tin, resulting in a smooth, even sheet of glass. The float process significantly reduces defects and produces glass sheets with a uniform thickness and size. This method is now the standard for high-quality plate glass production.

Challenges in the Industry

plate glass manufacturers

Despite its growth, the plate glass manufacturing industry faces several challenges. One of the primary issues is the raw material cost. The production of plate glass relies heavily on silica sand, soda ash, and limestone. Fluctuations in the prices of these raw materials can significantly impact production costs, directly affecting the bottom line for manufacturers.

Another challenge is energy consumption. The glass manufacturing process is highly energy-intensive, with large furnaces required to melt raw materials. Manufacturers are increasingly under pressure to adopt more sustainable practices and reduce their carbon footprint. This has led to a growing interest in renewable energy sources and energy-efficient technologies.

Moreover, competition from alternative materials, such as plastic and composite materials, poses a threat to the traditional plate glass market. While plate glass is preferred for its aesthetic and durability, the lightweight and shatter-resistant properties of alternatives can appeal to certain consumer segments, particularly in the automotive and construction sectors.

Future Prospects

Looking ahead, the plate glass manufacturing industry is poised for growth, driven by advancements in technology and increasing demand for eco-friendly products. Innovations such as high-performance glass with improved thermal insulation or energy efficiency are gaining traction, particularly in the context of green building initiatives. Manufacturers are investing in research and development to create smarter glass that can respond to environmental conditions or enhance building aesthetics.

The rise of the smart home trend also presents new opportunities. Smart glass, which can change its opacity or color in response to external stimuli, is becoming popular in modern architecture, offering energy-saving benefits as well as unique design elements. As consumer preferences shift towards sustainability and innovation, plate glass manufacturers who embrace these trends are likely to thrive.

Conclusion

In conclusion, the plate glass manufacturing industry is a dynamic field that combines traditional craftsmanship with modern technology. While challenges such as raw material costs and energy consumption persist, the industry's future looks brighter with the advent of innovative products and sustainable practices. As society continues to demand high-quality, eco-friendly materials, plate glass manufacturers will undoubtedly play a crucial role in shaping the built environment of tomorrow.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS