Aug . 30, 2025 04:20 Back to list

Safety & Security Laminated Glass Solutions

Industry Overview and Trends in Advanced Glazing

The demand for enhanced safety, security, and acoustic performance in modern architecture and automotive design has fundamentally reshaped the glass manufacturing sector. Central to this evolution is laminated glass, a composite material renowned for its superior properties. This specialized glass comprises two or more layers of glass bonded together with an interlayer, typically of Polyvinyl Butyral (PVB), SentryGlas® Plus (SGP), or Ethylene-vinyl acetate (EVA). Its unique construction ensures that, upon impact, the glass fragments adhere to the interlayer, significantly reducing the risk of injury and maintaining the structural integrity of the pane, a critical advantage over monolithic glass.

Current industry trends indicate a robust growth trajectory, driven by stringent building codes, increasing security concerns, and a global emphasis on energy efficiency. The market is witnessing a surge in applications requiring specialized solutions, such as hurricane-resistant windows for coastal regions, blast-mitigating glazing for high-security facilities, and advanced acoustic solutions for urban developments. Furthermore, the integration of smart technologies, including switchable privacy films and embedded sensors, is pushing the boundaries of traditional laminated glass, transforming it into a dynamic component of intelligent building systems. Innovations in interlayer materials, offering improved clarity, durability, and structural rigidity, continue to expand the design possibilities and performance envelope for architects and engineers. The demand for specific configurations, such as 5mm laminated glass, is particularly high in residential and light commercial applications where a balance of safety and cost-effectiveness is paramount.

Manufacturing Process and Technical Specifications of Laminated Glass

The production of laminated glass is a meticulously controlled multi-stage process designed to achieve optimal adhesion and structural integrity. Understanding this process is crucial for appreciating the technical advantages of the final product.

Process Flow:

- Glass Preparation: High-quality glass sheets, which can be annealed, heat-strengthened, or fully tempered, are precisely cut to size. These sheets undergo a rigorous washing and drying process to remove any contaminants that could compromise adhesion or optical clarity. This is a critical step to ensure a pristine bonding surface.

- Interlayer Lay-up: One or more layers of polymeric interlayer material (e.g., PVB, SGP, EVA) are carefully placed between the prepared glass sheets. The choice of interlayer directly impacts the glass's performance characteristics, such as impact resistance, stiffness, and post-breakage behavior. For instance, SGP offers significantly higher stiffness and tear resistance compared to PVB.

- Pre-pressing (Nipping/Pre-lamination): The assembled glass-interlayer sandwich is passed through rollers or a vacuum bag system to remove trapped air and create an initial bond between the glass and the interlayer. This stage typically involves heat to soften the interlayer, aiding in air evacuation and preliminary adhesion.

- Autoclaving: The pre-pressed assembly is then transferred to an autoclave, where it undergoes a high-temperature and high-pressure cycle. Typical conditions might be 130-150°C (266-302°F) and 10-14 bar (145-200 psi) for several hours. This process ensures complete fusion of the interlayer to the glass, eliminating residual air bubbles and creating a robust, permanent bond.

- Edge Sealing (Optional): For certain applications, especially those exposed to moisture or extreme environments, the edges of the laminated glass may be sealed to prevent delamination and enhance durability.

Testing Standards and Service Life:

Our products adhere to stringent international testing standards to guarantee performance and safety. These include ISO 12543 (Glass in building – Laminated glass and laminated safety glass), ANSI Z97.1 (Safety Glazing Materials Used in Buildings – Safety Performance Specifications and Methods of Test), and EN 14449 (Glass in building – Laminated glass and laminated safety glass – Evaluation of conformity/Product standard). When properly installed and maintained, laminated glass boasts an impressive service life exceeding 20 years, even in demanding conditions.

Target industries benefiting from the advanced properties of laminated glass include Architecture (building envelopes, interior partitions), Automotive (windshields, side glazing), Marine (portholes, deck windows), Security (banks, government facilities), and Energy (solar panel protection, BIPV). Its inherent advantages in energy saving (especially with low-e coatings) and corrosion resistance (for specific interlayers and edge treatments) make it ideal for petrochemical, metallurgy, and water supply & drainage sectors requiring robust, long-lasting glazing solutions.

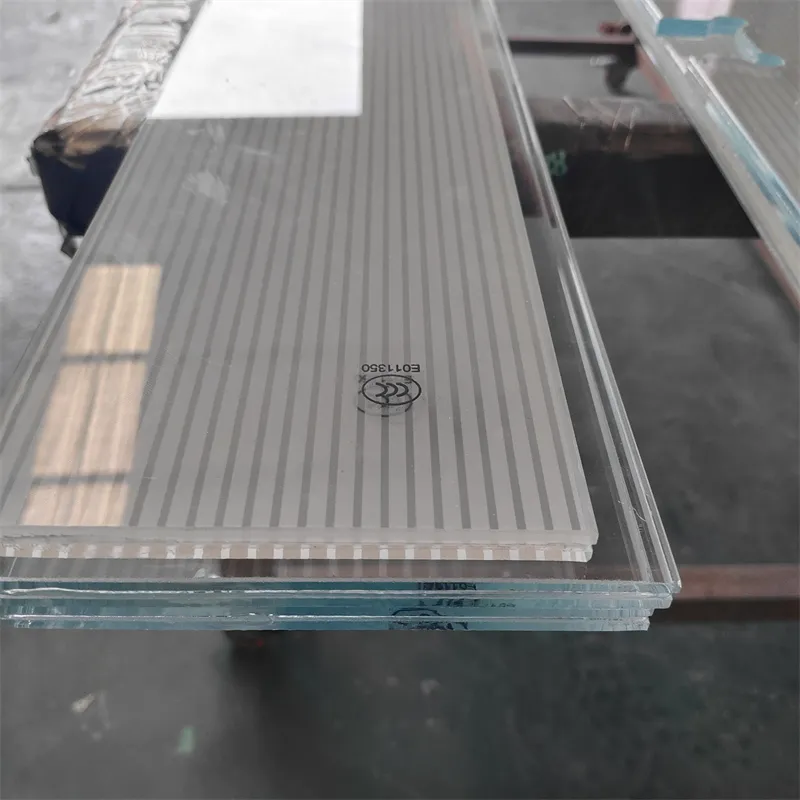

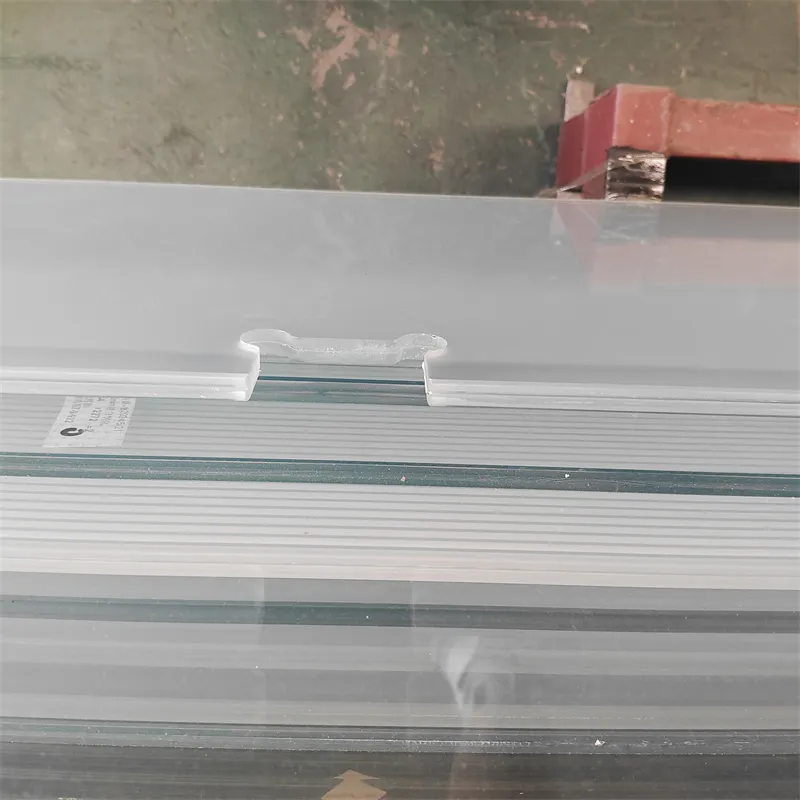

Figure 1: Cross-section illustrating the multi-layered structure of laminated glass.

Key Technical Parameters and Product Specifications

The performance of laminated glass is quantified by several critical technical parameters, which are essential for engineers and specifiers to consider. These parameters define its suitability for diverse application environments, from thermal and acoustic insulation to extreme impact resistance.

Interlayer Types and Performance Metrics:

- PVB (Polyvinyl Butyral): Standard interlayer, excellent adhesion, impact energy absorption, and UV filtering. Commonly available in thicknesses from 0.38mm to 1.52mm. Offers good sound attenuation and safety properties.

- SGP (SentryGlas® Plus): A rigid ionoplast interlayer offering significantly higher stiffness and tear strength than PVB. It provides enhanced post-breakage integrity, making it ideal for structural glazing, balustrades, and hurricane-resistant applications. SGP typically ranges from 0.89mm to 3.04mm.

- EVA (Ethylene-vinyl acetate): Often used for decorative laminates, specialized solar applications, and where specific adhesion properties are required. EVA offers good moisture resistance and allows for greater design flexibility with inclusions.

Specific product configurations like 6.38 laminated glass (3mm glass + 0.38mm PVB + 3mm glass) represent a common architectural solution balancing cost and performance. For more demanding applications, 12mm laminated glass (e.g., 6mm glass + 0.76mm PVB + 6mm glass or thicker SGP interlayers) provides superior structural integrity and acoustic performance.

Typical Laminated Glass Product Specifications:

| Specification | Total Thickness (mm) | Interlayer Type & Thickness (mm) | Sound Reduction Index (Rw) (dB) | UV Blockage (%) | Typical Applications |

|---|---|---|---|---|---|

| 3+0.38+3 (6.38mm) | 6.38 | PVB 0.38 | 30-32 | >99 | Residential windows, interior partitions, glass doors |

| 4+0.76+4 (8.76mm) | 8.76 | PVB 0.76 | 34-36 | >99 | Commercial windows, skylights, balustrades |

| 6+1.52+6 (13.52mm) | 13.52 | PVB 1.52 | 38-40 | >99 | Security glazing, overhead glazing, high-traffic areas |

| 8+1.52 SGP+8 (17.52mm) | 17.52 | SGP 1.52 | 40-42 | >99.5 | Structural glazing, balustrades, blast-resistant applications |

Note: Acoustic and thermal performance values are indicative and can vary based on specific glass types (e.g., clear, low-e, tinted) and testing methodologies.

Diverse Application Scenarios and Technical Advantages

The versatility and superior performance of laminated glass make it indispensable across a multitude of industries and application environments. Its core advantages address critical requirements for safety, security, and environmental control.

Primary Application Scenarios:

- Architectural Glazing: From building facades and curtain walls to skylights, canopies, and interior partitions, laminated glass provides essential safety against breakage and fall-through. Its aesthetic versatility allows for integration into modern, minimalist designs, including frameless laminated glass doors.

- Security Applications: Used in banks, government buildings, jewelry stores, and residential properties to resist forced entry, bullet penetration, and blast impacts. Multi-layered laminates with thicker interlayers (e.g., SGP) are crucial here.

- Noise Control: Its inherent dampening properties make it ideal for windows and facades in noisy environments, such as near airports, highways, or urban centers. The viscoelastic interlayer effectively absorbs sound vibrations.

- Automotive Industry: Essential for vehicle windshields, providing occupant protection in collisions by preventing shattering and limiting occupant ejection.

- Marine and Specialized Transport: Used in naval vessels and luxury yachts for portholes and windows, offering robustness against high-pressure water and extreme weather conditions.

- Energy Efficiency: When combined with low-emissivity (low-e) coatings or incorporated into insulated glazing units (IGUs), laminated glass contributes significantly to thermal performance, reducing heating and cooling loads in buildings.

Core Technical Advantages:

- Enhanced Safety: The primary benefit. Upon breakage, glass fragments adhere to the interlayer, preventing dangerous shards from scattering and maintaining a barrier, crucial for overhead glazing or high-traffic areas.

- Superior Security: The interlayer significantly increases resistance to forced entry, providing a delay mechanism against intruders. Multi-ply laminates offer even higher levels of protection.

- Acoustic Insulation: The viscoelastic nature of the interlayer effectively dampens sound vibrations, resulting in a higher Sound Reduction Index (SRI) compared to monolithic glass of the same thickness.

- UV Filtration: The PVB interlayer blocks over 99% of harmful UV radiation, protecting interiors, furnishings, and occupants from fading and damage, without compromising visible light transmission.

- Energy Efficiency & Thermal Performance: When paired with low-e coatings or used in insulating glass units, laminated glass improves U-values, reducing heat transfer and contributing to lower energy consumption. This is particularly advantageous in petrochemical facilities where temperature control is critical, or in high-rise buildings seeking LEED certification.

- Corrosion Resistance: While glass itself is highly resistant, certain specialized interlayers or hermetically sealed edge solutions can enhance the overall system's durability against environmental corrosion, especially relevant in coastal, marine, or industrial environments.

Figure 2: Laminated glass installed in a modern architectural facade, showcasing clarity and security.

Vendor Comparison and Customized Solutions

Selecting the right supplier for laminated glass is critical for ensuring project success, compliance with specifications, and long-term performance. A comprehensive evaluation of vendor capabilities, product quality, and service offerings is essential.

Key Considerations for Vendor Selection:

- Certifications & Compliance: Verify adherence to international standards (e.g., ISO, CE, SGCC, CCC). This ensures product quality and suitability for specific regulatory environments.

- Manufacturing Capabilities: Assess production capacity, maximum panel sizes, and the ability to process various glass types and interlayers (PVB, SGP, EVA, specialty films).

- R&D and Innovation: A strong R&D focus indicates a vendor's ability to offer cutting-edge solutions and adapt to evolving market demands, such as advanced security or acoustic requirements.

- Technical Support & Expertise: The availability of experienced technical teams for project consultation, specification guidance, and after-sales support.

- Lead Times & Logistics: Efficiency in order fulfillment, particularly for large or customized projects, and robust global logistics capabilities.

Comparative Analysis of Laminated Glass Suppliers (Illustrative):

| Feature/Vendor | Vendor A (Global Leader) | Vendor B (Specialty Manufacturer) | Vendor C (Regional/Cost-Effective) |

|---|---|---|---|

| Certifications | ISO 9001, CE, SGCC, AS/NZS | ISO 9001, CE, ASTM | ISO 9001, CCC |

| Max Panel Size | 3300 x 12000 mm | 2400 x 6000 mm | 2200 x 4000 mm |

| Interlayer Range | PVB, SGP, EVA, Acoustic PVB, Specialty films | SGP (core focus), PVB | PVB, basic EVA |

| Customization Options | Extensive: shapes, coatings, colors, inclusions, bent glass | High: complex geometries, specific SGP thicknesses | Limited: standard shapes, basic tints |

| Typical Lead Time (Standard) | 2-3 weeks | 3-5 weeks | 2-4 weeks |

Customized Solutions:

Modern projects frequently demand more than off-the-shelf solutions. Our capabilities extend to comprehensive customization for laminated glass products. This includes:

- Glass Type & Thickness: Combining annealed, heat-strengthened, or fully tempered glass to achieve specific mechanical properties. Available in a range from 5mm laminated glass for interior features to multi-ply systems exceeding 50mm for specialized security.

- Interlayer Configuration: Tailoring interlayer type (PVB, SGP, EVA), thickness, and number of layers to meet precise security, acoustic, or structural requirements.

- Coatings & Tints: Integrating low-e coatings for thermal performance, reflective coatings for solar control, or colored interlayers for aesthetic objectives.

- Shape & Size: Producing custom shapes (e.g., curves, irregular geometries) and oversized panels to accommodate unique architectural designs.

- Specialty Inclusions: Incorporating mesh, fabrics, or smart films within the laminate for decorative, privacy, or functional purposes.

Figure 3: Advanced automated production line for high-volume laminated glass manufacturing.

Application Case Studies and Client Experience

Our extensive experience in the field of laminated glass is demonstrated through successful collaborations on diverse, high-profile projects. These case studies highlight our capability to deliver tailored solutions that meet complex architectural and functional demands, ensuring client satisfaction and project integrity.

Case Study 1: High-Rise Corporate Headquarters Facade

Challenge: A prominent financial institution required a façade for its new 40-story corporate headquarters that offered exceptional safety, advanced thermal performance, and superior acoustic insulation against urban noise, while maintaining an aesthetic of transparency and modern elegance. Wind load and solar gain were significant concerns.

Solution: We engineered a bespoke solution utilizing an insulated 12mm laminated glass (6mm low-e tempered glass + 1.52mm SGP interlayer + 6mm heat-strengthened glass) as the outer pane of a high-performance IGU. The SGP interlayer provided enhanced post-breakage integrity, crucial for overhead safety, and structural strength against extreme wind pressures. The low-e coating significantly reduced solar heat gain, contributing to a 25% reduction in cooling costs. The robust lamination and air gap in the IGU achieved an impressive Rw of 42dB, effectively mitigating street noise.

Outcome: The project was completed on schedule, resulting in a visually stunning, highly energy-efficient, and supremely safe building envelope. The client praised the detailed technical consultation and the seamless integration of complex specifications, noting the significant improvement in occupant comfort and energy savings.

Case Study 2: Secure Banking Facility Glazing

Challenge: A regional bank required an upgrade to its branch network, focusing on enhanced security for teller lines and public-facing areas without compromising natural light or an inviting atmosphere. The primary concern was ballistic and forced-entry resistance.

Solution: We supplied multi-ply laminated glass units, custom-designed to meet UL Level 3 ballistic resistance standards, consisting of multiple layers of glass and thick PVB interlayers. These units were integrated into existing framing systems with minimal structural modifications. We also provided laminated glass door panels for secure entry points, manufactured with similar ballistic properties but allowing clear visibility.

Outcome: The bank reported a significant increase in staff and customer confidence due to the visible security enhancements. The project demonstrated our ability to deliver highly specialized, certified security glazing solutions without disrupting ongoing operations, earning repeat business for subsequent branch renovations.

Case Study 3: Boutique Hotel Soundproofing

Challenge: A boutique hotel located in a bustling downtown area struggled with noise complaints from guests due to street traffic and nightlife. The objective was to dramatically improve in-room acoustic comfort while maintaining existing window aesthetics.

Solution: Our team recommended a specific acoustic 6.38 laminated glass (3mm glass + 0.76mm acoustic PVB interlayer + 3mm glass) for all guest room windows. The specialized acoustic PVB interlayer is engineered for superior sound dampening. This was often coupled with an insulating air gap and another layer of glass for maximum sound attenuation in an IGU setup.

Outcome: Post-installation, the hotel received overwhelmingly positive feedback regarding the dramatic reduction in noise levels, directly translating to improved guest satisfaction scores and a reduction in complaints. This project showcased our expertise in acoustic glazing and our commitment to tailored solutions for specific environmental challenges.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Building strong, trustworthy relationships with our B2B partners is paramount. We provide clear commitments regarding product performance, delivery, and after-sales support to ensure confidence in our laminated glass solutions.

Frequently Asked Questions (FAQ):

- Q: What is the primary difference between PVB and SGP interlayers in laminated glass?

- A: PVB (Polyvinyl Butyral) is the most common interlayer, offering excellent safety, UV protection, and acoustic insulation. SGP (SentryGlas® Plus) is a more rigid, high-performance ionoplast interlayer that provides significantly higher stiffness, tear strength, and post-breakage integrity, making it suitable for structural glazing and extreme weather conditions. SGP also offers enhanced clarity.

- Q: Can laminated glass be cut or drilled after tempering?

- A: No. If the glass plies within the laminate are tempered, they cannot be cut, drilled, or altered in any way after the tempering process. Any attempts would cause the glass to shatter into small, blunt pieces. All cutting, drilling, and edge work must be performed before tempering and lamination.

- Q: What thicknesses are available for bullet-resistant laminated glass?

- A: Bullet-resistant laminated glass varies significantly in thickness, typically ranging from 20mm to over 80mm, depending on the required ballistic protection level (e.g., UL Levels 1-8). These products use multiple layers of glass and thick specialized interlayers to absorb and disperse impact energy.

- Q: Is laminated glass recyclable?

- A: While more complex than recycling monolithic glass, advancements in technology are making laminated glass increasingly recyclable. Specialized processes can separate the glass from the interlayer, allowing both components to be reused or repurposed, aligning with sustainability goals.

Lead Time & Fulfillment Details:

Our streamlined production and logistics ensure efficient order fulfillment.

- Standard Products: For common configurations (e.g., 6.38 laminated glass, 5mm laminated glass, clear PVB), typical lead times range from 2 to 4 weeks, depending on order volume and current production schedules.

- Custom & Specialized Orders: For bespoke solutions involving specific interlayers, complex shapes, or large volumes (e.g., extensive 12mm laminated glass for a skyscraper), lead times generally range from 4 to 8 weeks. Project-specific timelines are provided during the quotation phase.

- Logistics: We offer flexible shipping options, including sea freight, air freight, and ground transport, tailored to project deadlines and geographical requirements. All shipments are securely packaged and insured.

Warranty Commitments:

We stand behind the quality and durability of our products. Our laminated glass comes with a comprehensive warranty against manufacturing defects and delamination under normal operating conditions.

- Standard Warranty: A typical 10-year warranty covers significant optical defects and delamination for interior applications.

- Extended Warranty Options: Extended warranty periods are available for specific high-performance products or projects upon request and agreement.

- Claims Process: Our dedicated customer support team facilitates a clear and efficient process for any warranty claims, ensuring prompt resolution.

Customer Support Information:

Our commitment to our clients extends beyond delivery. We provide robust after-sales support to ensure the long-term satisfaction and success of your projects.

- Technical Assistance: Our team of glass experts is available to provide technical guidance on installation, maintenance, and performance optimization.

- Dedicated Account Management: Each client is assigned a dedicated account manager to ensure personalized service and seamless communication throughout the project lifecycle.

- Contact Channels: Reach us via phone, email, or through our online portal for any inquiries or support needs.

Authoritative References

- ISO 12543: Glass in building – Laminated glass and laminated safety glass. International Organization for Standardization.

- ANSI Z97.1: Safety Glazing Materials Used in Buildings – Safety Performance Specifications and Methods of Test. American National Standards Institute.

- EN 14449: Glass in building – Laminated glass and laminated safety glass – Evaluation of conformity/Product standard. European Committee for Standardization.

- ASTM C1172: Standard Specification for Laminated Architectural Flat Glass. ASTM International.

- Wang, L., & Lim, H. S. (2015). Recent developments in laminated glass: A review. Construction and Building Materials, 94, 25-39.

- Vallabhan, C. V. G. (2007). Laminated glass in structures: A review of current practices. Journal of Architectural Engineering, 13(4), 169-178.

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS