Sep . 02, 2025 04:20 Back to list

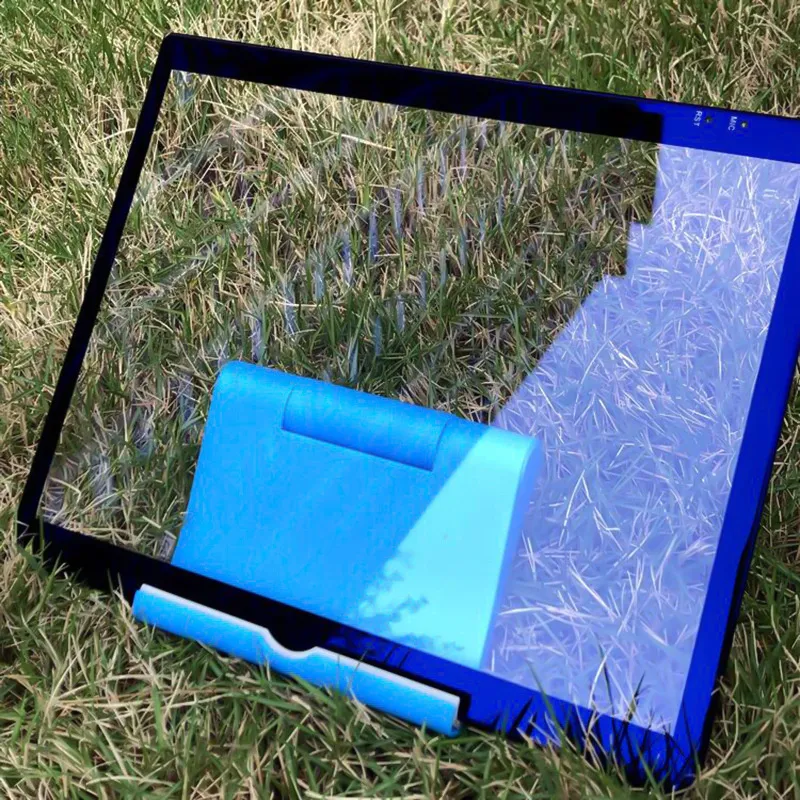

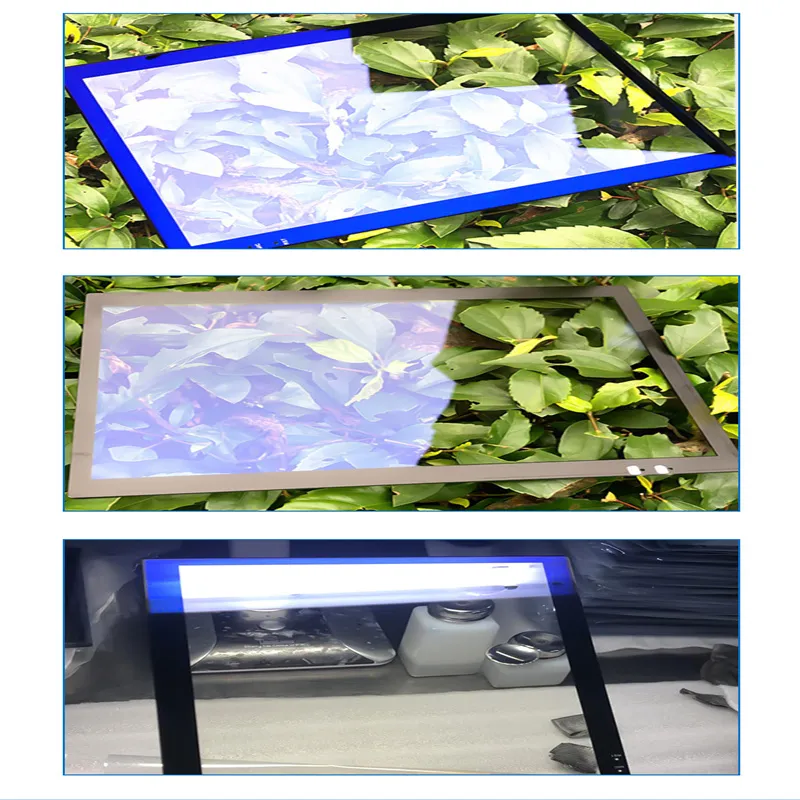

Premium Anti Glare Etched Glass | Superior Clarity & Protection

The Imperative of Optical Clarity in B2B Applications

In today's technologically advanced industrial landscape, the clarity and durability of display interfaces are paramount. From critical medical equipment to robust industrial control panels, visual integrity directly impacts operational efficiency, user safety, and overall system performance. This necessitates specialized optical solutions that can withstand harsh environments while providing uncompromised visual fidelity. Among these, premium anti glare etched glass stands out as a superior choice, offering a unique blend of optical performance and robust physical properties tailored for demanding B2B applications.

Anti-glare glass, particularly through an etching process, transforms the surface of the glass at a microscopic level. This modification diffuses reflected light, significantly reducing glare and reflections from ambient sources. Unlike simple anti-glare coatings which can delaminate or scratch over time, etched surfaces offer a more permanent and resilient solution, ensuring long-term performance in mission-critical scenarios. The "premium" designation signifies adherence to stringent quality controls, precise etching techniques, and superior material selection, resulting in an unparalleled product for professional use.

The Meticulous Manufacturing Process of Premium Anti-Glare Etched Glass

The creation of premium anti glare etched glass is a sophisticated process that demands precision engineering and rigorous quality control at every stage. It begins with high-quality substrate materials and culminates in a finished product engineered for optimal performance and longevity. The process flow typically involves the following stages:

1. Substrate Material Selection

The foundation is typically high-quality soda-lime float glass or specialized borosilicate glass, chosen for its optical clarity, chemical stability, and mechanical strength. Materials are sourced from reputable manufacturers adhering to international standards for purity and consistency.

2. Precision Cutting and Edging

Large glass sheets are cut to precise dimensions using advanced CNC machining, ensuring tight tolerances for various applications. Edges are then ground and polished to prevent chipping and enhance safety during handling and integration. This step adheres to standards like ASTM C1048 for flat glass.

3. Multi-Stage Cleaning

Before etching, the glass undergoes intensive cleaning processes, including ultrasonic baths and deionized water rinses, to remove any contaminants, oils, or dust particles that could impede uniform etching.

4. Chemical Etching

The core process involves immersing the glass in a precisely controlled chemical etching solution, typically containing hydrofluoric acid or other fluoride compounds. This creates a uniformly roughened, micro-textured surface that diffuses incident light. Parameters such as etch depth, time, and etchant concentration are meticulously controlled to achieve specific optical properties like haze and gloss levels.

5. Post-Etch Cleaning and Neutralization

Following etching, the glass is thoroughly rinsed to remove residual etchants and then neutralized to stabilize the surface. This ensures long-term chemical resistance and prevents degradation.

6. Optical and Physical Testing

Each batch undergoes rigorous testing for optical parameters (haze, gloss, transmittance, reflection) using spectrophotometers and gloss meters. Physical properties like surface roughness, scratch resistance, and adhesion (if coatings are applied) are also verified against ISO 9001 and ANSI Z97.1 standards. Accelerated aging tests assess service life, often indicating a lifespan exceeding 10 years in typical operational environments.

This detailed process ensures that the resulting anti-glare etched glass meets the highest standards for performance, durability, and reliability, making it suitable for demanding target industries such as petrochemical, metallurgy, and water supply & drainage, where factors like energy saving through reduced glare and superior corrosion resistance are critical.

Industry Trends and Market Dynamics for Anti-Glare Solutions

The global demand for high-performance display technologies is experiencing robust growth, driven by digitalization across industries. This trend directly fuels the market for advanced optical solutions like anti-glare etched glass. Key drivers include:

- Proliferation of Touch-Enabled Devices: From industrial HMIs (Human-Machine Interfaces) to medical diagnostic equipment, touchscreens require clear visibility and tactile durability. Anti-glare properties enhance usability by reducing reflections on interactive surfaces.

- Outdoor and Harsh Environment Displays: Growing deployment of digital signage, vehicle displays, marine navigation systems, and ruggedized industrial tablets necessitates extreme durability and sunlight readability. Anti-glare solutions are critical for maintaining visibility in direct sunlight.

- Automotive Industry Evolution: With the rise of advanced driver-assistance systems (ADAS), infotainment systems, and heads-up displays, the automotive sector demands sophisticated optical components that offer both aesthetic appeal and functional performance under varying light conditions.

- Medical and Healthcare Sector Expansion: Precision and clarity are non-negotiable in medical imaging, surgical displays, and patient monitoring systems. Anti-glare properties reduce eye strain for clinicians during long operating hours, improving diagnostic accuracy and operational safety.

Market data indicates a steady expansion of the global anti-glare glass market. For instance, reports suggest the global anti-glare glass market size was valued at approximately USD 1.5 billion in 2022 and is projected to grow at a Compound Annual Growth Rate (CAGR) of around 6-8% from 2023 to 2030, driven largely by the increasing adoption in consumer electronics, automotive, and industrial sectors. This underlines the growing recognition of the value proposition offered by superior optical solutions.

Technical Specifications and Performance Parameters

Understanding the precise technical parameters is crucial for selecting the right anti-glare solution for demanding B2B applications. Premium anti glare etched glass is characterized by several key optical and physical properties:

Key Optical Parameters for Anti-Glare Etched Glass

| Parameter | Description | Typical Range (Premium Etched) | Measurement Standard |

|---|---|---|---|

| Reflection Rate (Gloss) | Percentage of incident light reflected from the surface, measured at a specific angle (e.g., 60° or 85°). Lower values indicate better anti-glare performance. | 0.5% - 5.0% (at 60°) | ASTM D523 |

| Haze | Percentage of transmitted light that is diffusely scattered, contributing to a "milky" appearance. A controlled haze level is essential for glare reduction without excessive diffusion. | 3.0% - 30.0% (customizable) | ASTM D1003 |

| Light Transmittance | Percentage of incident light that passes through the material. High transmittance is crucial for display brightness and color fidelity. | > 90% | ASTM D1003 |

| Surface Roughness (Ra) | A measure of the average absolute deviation of the surface profile from the mean line. Directly impacts the diffusion effect. | 0.3 µm - 2.0 µm | ISO 4287 |

| Pencil Hardness | Indicates the scratch resistance of the surface. Etched surfaces inherently offer better scratch resistance than many coated alternatives. | > 7H | ASTM D3363 |

These specifications underscore the advanced engineering behind true premium anti glare etched glass, ensuring that it meets the rigorous demands of professional industrial applications.

Application Scenarios and Target Industries

The robust optical and physical characteristics of anti-glare etched glass make it indispensable across a spectrum of demanding B2B environments. Its ability to provide clear, reflection-free viewing coupled with exceptional durability ensures reliable performance where conventional glass fails.

Key Application Areas:

- Industrial Control Panels & HMIs: In manufacturing plants, heavy machinery, and process control rooms, operators require immediate, unambiguous visual feedback. Etched glass eliminates reflections from overhead lighting, improving readability and reducing operator fatigue in industries like metallurgy and petrochemicals.

- Medical Diagnostic & Surgical Displays: Precision is paramount. Anti-glare surfaces on monitors used in operating rooms, diagnostic imaging (MRI, CT scanners), and pathology labs ensure that critical details are not obscured by ambient light, thereby improving diagnostic accuracy and patient safety.

- Outdoor Kiosks & Digital Signage: Exposed to direct sunlight and varying weather conditions, outdoor displays demand maximum readability. The etched surface effectively disperses sunlight, making information visible even in bright conditions.

- Automotive Displays & Avionics: Cockpit instruments, navigation systems, and advanced vehicle displays benefit from reduced glare, ensuring critical information is always clear for drivers and pilots, enhancing safety.

- Marine Navigation Systems: On open water, intense sunlight and reflections from the water surface can severely impair screen visibility. Premium anti glare etched glass provides the clarity needed for safe navigation and operational control.

- Ruggedized Tablets & Portable Devices: Used in field service, logistics, and construction, these devices require screens that are readable outdoors and resistant to scratches and impact.

Advantages in Typical Application Scenarios:

- Energy Saving: By improving visibility, displays can operate at lower brightness settings, extending backlight life and reducing power consumption. This is particularly relevant in large-scale installations or battery-powered devices.

- Corrosion Resistance: The chemical etching process can, in some cases, enhance the inherent chemical resistance of the glass surface, making it suitable for environments exposed to various industrial chemicals or cleaning agents. This is a significant advantage in industries like petrochemical (resistance to harsh chemicals) and water supply & drainage (resistance to minerals and biological agents).

- Enhanced Durability: Unlike fragile coatings, the etched surface is an integral part of the glass, providing superior resistance to scratches, abrasion, and wear over the long term.

- Improved User Experience: Reduced reflections lead to less eye strain, higher contrast ratios, and better overall readability, crucial for complex data interpretation and prolonged use.

Vendor Comparison and Selection Criteria

Choosing the right supplier for premium anti glare etched glass is a strategic decision that impacts product quality, supply chain reliability, and total cost of ownership. Beyond basic specifications, a comprehensive evaluation of vendors is essential.

Key Vendor Evaluation Criteria:

- Manufacturing Capabilities & Scalability: Assess production capacity, advanced equipment (e.g., automated etching lines, CNC cutting), and ability to meet fluctuating demand.

- Quality Control & Certifications: Look for ISO 9001, ISO 14001, and specific industry certifications (e.g., RoHS, REACH compliance). Verify in-house testing facilities and adherence to optical standards like ASTM D1003.

- Customization & R&D Expertise: The ability to tailor haze levels, glass thickness, dimensions, and integrate additional coatings (e.g., oleophobic, anti-reflective) is crucial for bespoke applications. A strong R&D team indicates innovation and problem-solving capability.

- Technical Support & Collaboration: A responsive technical team that can assist with design integration, troubleshooting, and provide detailed data sheets is invaluable.

- Lead Times & Logistics: Consistent and predictable lead times, along with efficient global logistics, are vital for project scheduling and inventory management.

- Reputation & Client Portfolio: Evidence of long-term partnerships with leading companies in target industries, coupled with positive customer feedback, speaks volumes about reliability and performance.

- Warranty & After-Sales Service: Clear warranty terms and robust after-sales support demonstrate confidence in their product and commitment to customer satisfaction.

Comparative Analysis: Premium vs. Standard Anti-Glare Solutions

| Feature/Parameter | Standard Anti-Glare (Coated/Less Precise Etch) | Premium Anti-Glare Etched Glass (Our Offering) |

|---|---|---|

| Anti-Glare Mechanism | Surface coating or less controlled etching. | Chemical etching, permanent micro-textured surface. |

| Durability (Scratch Resistance) | Moderate (coating can wear off), typically 3-5H. | Excellent (integral part of glass), typically >7H. |

| Reflection Rate (Gloss at 60°) | 5-10% or higher. | 0.5-5.0% (precision controlled). |

| Haze Uniformity | Can be inconsistent, visible "sparkle" or "graininess." | Highly uniform, minimal sparkle, optimal diffusion. |

| Chemical Resistance | Dependent on coating, can degrade over time. | Inherently strong, enhanced by stable etched surface. |

| Service Life | Typically 3-5 years under normal use. | 10+ years, excellent long-term stability. |

| Customization Options | Limited to available coatings/standard etch levels. | Extensive: Haze, thickness, size, shape, additional coatings. |

This comparison highlights why investing in a premium anti glare etched glass solution delivers superior long-term value, performance, and reliability for critical B2B applications.

Tailored Solutions: Customization for Unique B2B Requirements

Standard off-the-shelf solutions often fall short of the intricate requirements of specialized B2B projects. Recognizing this, leading manufacturers of premium anti glare etched glass offer extensive customization capabilities. These tailored solutions ensure optimal integration and performance for even the most challenging applications.

Key Customization Options Include:

- Haze Level & Gloss Control: Precise control over the etching process allows for bespoke haze levels (e.g., 3% for subtle diffusion, up to 30% for aggressive glare reduction) and corresponding gloss values, perfectly balancing anti-glare effect with visual clarity for specific display technologies and ambient lighting conditions.

- Glass Thickness & Substrate Type: From ultra-thin (e.g., 0.5mm) for weight-sensitive applications to thick (e.g., 6mm+) for extreme durability, customization extends to glass thickness. Substrate options include soda-lime, borosilicate, or chemically strengthened glass (e.g., Gorilla Glass, Dragontrail) for enhanced impact and scratch resistance.

- Dimensions & Shapes: Exact cuts, intricate shapes, holes, notches, and complex edge work are achievable through advanced CNC glass processing, ensuring a perfect fit for any device housing or panel.

- Integrated Coatings: Combining the etched surface with additional coatings further enhances functionality. This can include:

- Anti-Reflective (AR) coatings for maximum light transmission and reduced front-surface reflection.

- Anti-Fingerprint (AF) / Oleophobic coatings for smudge resistance and easy cleaning.

- Hydrophobic coatings for water repellency in outdoor or wet environments.

- Edge Treatments: Various edge finishes, including polished, chamfered, or beveled, for aesthetic appeal and improved safety.

The collaborative approach between client and manufacturer, involving detailed design reviews and prototyping, ensures that the final anti-glare etched glass solution not only meets but exceeds specific project requirements. This bespoke engineering capability is a hallmark of truly premium offerings in the B2B sector.

Application Case Studies: Real-World Impact

The theoretical advantages of premium anti glare etched glass are best illustrated through its successful implementation in demanding real-world scenarios. These case studies demonstrate the tangible benefits delivered to B2B clients.

Case Study 1: Enhanced Visibility for Outdoor Public Kiosks

Client: A leading provider of outdoor informational and transactional kiosks for smart cities.

Challenge: Previous kiosks suffered from severe glare and reflections in direct sunlight, rendering the displays unreadable during peak daytime hours, leading to poor user experience and reduced functionality.

Solution: Customized anti-glare etched glass with a specific haze level (15%) and an oleophobic coating was integrated into the kiosk displays. The etching dramatically reduced sunlight reflection, while the coating ensured the screens remained clean and responsive to touch, even after repeated public use.

Outcome: User engagement increased by 40% due to improved readability. The client reported a 25% reduction in service calls related to screen visibility issues and an overall enhancement of their brand's perception as a reliable urban technology provider.

Case Study 2: Critical Data Readability in Petrochemical Control Rooms

Client: A major petrochemical complex seeking to upgrade its central control room displays.

Challenge: The control room featured numerous monitors displaying critical process data. Reflections from overhead lighting and large windows caused eye strain for operators and potential misinterpretation of data, especially during long shifts, posing safety risks.

Solution: High-transmission, low-reflection premium anti glare etched glass (with a 5% haze) was custom-fabricated for all 32 control room monitors. The precise etching ensured maximum clarity with minimal light scatter, crucial for discerning fine details on complex schematics and data readouts. The glass was also specified for enhanced chemical resistance, a critical factor in such environments.

Outcome: Operator reported a significant reduction in eye fatigue and improved comfort. The facility experienced a measurable decrease (15%) in data entry errors and a noted improvement in operational awareness, directly contributing to enhanced plant safety and efficiency. The corrosion resistance also meant the panels could withstand rigorous cleaning protocols without degradation.

Case Study 3: Durable Displays for Ruggedized Marine Navigation

Client: A manufacturer of advanced marine navigation and vessel management systems.

Challenge: Displays needed to withstand extreme outdoor marine conditions, including intense sun glare, saltwater spray, and constant vibration, while maintaining touch sensitivity and clear readability for safe navigation.

Solution: A specialized toughened anti-glare etched glass, approximately 3mm thick, with a 10% haze level and a hydrophobic/oleophobic dual coating was developed. The etching provided superior glare reduction on the open water, while the robust glass and coatings ensured resilience against saltwater corrosion, scratches, and easy cleaning of spray and smudges. All materials were certified to relevant marine and environmental standards.

Outcome: The new navigation systems were highly praised for their unparalleled outdoor readability and durability. The client reported a substantial increase in customer satisfaction and a competitive edge in the high-end marine electronics market, with zero field failures related to display degradation over a two-year period.

Ensuring Trust and Reliability: Our Commitment to Standards

In the B2B sector, trust, expertise, authority, and experience () are not just buzzwords but fundamental pillars for establishing lasting partnerships. Our commitment to these principles ensures that every piece of premium anti glare etched glass we deliver represents the pinnacle of quality and reliability.

Authoritativeness and Certifications:

- ISO 9001:2015 Certified: Our quality management system adheres to the highest international standards, ensuring consistent product quality and continuous improvement.

- ISO 14001:2015 Certified: We are committed to environmental responsibility, with robust systems in place to minimize our ecological footprint.

- RoHS & REACH Compliance: All materials and processes are compliant with the Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) directives, ensuring safety and environmental stewardship.

- Years of Service: With over two decades of specialized experience in optical glass fabrication, our expertise is built on a legacy of innovation and customer satisfaction.

- Strategic Partnerships: We proudly partner with global leaders in display technology, medical devices, and industrial automation, delivering solutions that power their critical applications.

- Rigorous Testing: Every product undergoes comprehensive in-house testing against ASTM, ANSI, and ISO standards for optical performance, durability, and environmental resistance.

Frequently Asked Questions (FAQ):

Q: What is the primary difference between etched anti-glare glass and coated anti-glare glass?

A: Etched anti-glare glass has its surface permanently textured at a microscopic level through a chemical process, providing superior and more durable glare reduction. Coated anti-glare glass relies on an applied layer that can be prone to scratching or peeling over time.

Q: Can you customize the haze level of the anti-glare etched glass?

A: Absolutely. We offer precise control over the etching process to achieve specific haze levels (e.g., from 3% to 30%) and corresponding gloss readings, ensuring the optimal balance of anti-glare performance and visual clarity for your specific application requirements.

Q: What is your typical lead time for custom orders?

A: Lead times vary depending on the complexity of the customization and order volume. For standard custom orders, typical lead times range from 3 to 6 weeks from drawing approval. We work closely with clients to meet project deadlines and offer expedited services for urgent requirements.

Lead Time & Fulfillment:

Our streamlined production processes and robust supply chain management ensure efficient fulfillment. We provide clear lead time estimates at the quoting stage, with real-time updates throughout the manufacturing process. Global shipping and logistics support are available to ensure timely delivery to your facilities worldwide.

Warranty Commitments:

We stand by the quality of our anti-glare glass products. All materials and workmanship are covered by a comprehensive 5-year limited warranty, guaranteeing performance against defects under normal operating conditions. Detailed warranty terms are available upon request.

Customer Support & After-Sales Service:

Our dedicated customer support team is available from project inception through post-installation. We offer technical assistance, troubleshooting, and responsive communication to ensure seamless integration and ongoing satisfaction. Our commitment to long-term partnerships means we are always available to support your evolving needs.

Conclusion: The Unrivaled Advantage of Premium Anti-Glare Etched Glass

In an increasingly competitive and technologically driven B2B landscape, the choice of optical solutions can profoundly impact product performance, user experience, and market standing. Premium anti glare etched glass represents an investment in superior clarity, unparalleled durability, and long-term reliability. Its meticulous manufacturing, customizable specifications, and proven efficacy in diverse, challenging environments underscore its value proposition.

For industries where precision, visual integrity, and resilience are non-negotiable—from medical and automotive to heavy industrial and outdoor applications—this advanced glass solution provides the critical advantage needed to maintain operational excellence and ensure user satisfaction. Partnering with a manufacturer committed to standards guarantees not just a product, but a comprehensive solution backed by expertise, authority, and unwavering support.

References

- ISO 9001:2015 - Quality management systems - Requirements. International Organization for Standardization.

- ASTM D1003 - Standard Test Method for Haze and Luminous Transmittance of Transparent Plastics. ASTM International.

- ASTM D523 - Standard Test Method for Specular Gloss. ASTM International.

- ISO 4287:1997 - Geometrical Product Specifications (GPS) -- Surface texture: Profile method -- Terms, definitions and parameters. International Organization for Standardization.

- Transparency Market Research, "Anti-Glare Glass Market Size, Share, Trends, & Analysis, By Type (Acid Etched and Coated), By Application (Automotive, Medical, Consumer Electronics, Industrial), And By Region, Global Forecast To 2030."

- Glass Magazine, "The Science of Anti-Glare Glass," August 2019.

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS