Dec . 03, 2024 18:02 Back to list

process of tempered glass

The Process of Tempered Glass An In-Depth Overview

Tempered glass, known for its strength and safety features, is a crucial material in modern architecture and design. Its production process is sophisticated, involving careful control of temperature and time to enhance its durability. Understanding this process is essential for manufacturers, architects, and consumers alike.

What is Tempered Glass?

Tempered glass, also referred to as toughened glass, is a type of safety glass that has been treated through controlled thermal or chemical processes to increase its strength compared to standard glass. It is designed to withstand higher levels of stress and temperature changes, making it ideal for various applications, including windows, doors, shower enclosures, and glass facades.

The Production Process

The manufacturing process of tempered glass involves several key steps cutting, shaping, and thermal treatment. Let’s break down these stages

1. Cutting and Shaping The process begins with a standard piece of float glass, which is cut to the desired dimensions. This glass is typically manufactured using the float glass process where molten glass is poured onto molten tin to create a smooth, uniform sheet. After cutting, the edges of the glass are often polished to ensure safety and aesthetics, as sharp edges can pose a risk of injury.

2. Cleaning Once cut and shaped, the glass is thoroughly cleaned. Any dust, grease, or foreign materials must be removed to ensure the thermal treatment is effective. A clean surface is crucial, as residues can damage the glass during the heating and cooling stages.

3. Heating The cleaned glass is then placed in a tempering furnace, where it is heated to temperatures around 600 to 700 degrees Celsius (1112 to 1292 degrees Fahrenheit). This rapid heating causes the glass to expand, and its molecular structure starts to change as it reaches its glass transition temperature.

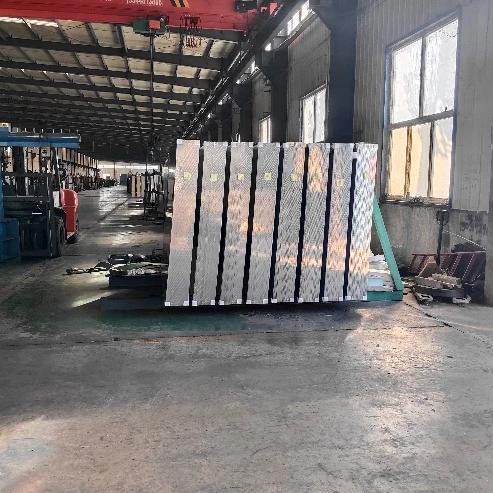

process of tempered glass

4. Quenching After the heating phase, the glass is then rapidly cooled in a process known as quenching. This involves forcing cool air onto the surface of the glass, which cools it quickly and creates a significant difference in temperature between the outer surface and the inner core. The rapid cooling causes the outer layers of the glass to solidify faster than the inner layers, putting the outer surface under compression and the inner surface under tension. This compression is what gives tempered glass its added strength.

5. Cooling and Stabilizing Once the glass has been quenched, it is allowed to cool to room temperature. This cooling phase is crucial for stabilizing the internal stresses within the glass. The final product is a piece of glass that is much stronger than its untempered counterpart, capable of withstanding impacts and temperature variations.

6. Inspection and Quality Control The tempered glass undergoes rigorous inspection and quality control processes to ensure it meets safety standards. Any imperfections such as bubbles, waves, or irregularities are identified and rejected, ensuring only the highest quality products reach consumers.

Benefits of Tempered Glass

The benefits of tempered glass are numerous. Its enhanced strength means it is less likely to break under stress. In the event that it does shatter, it breaks into small, blunt pieces rather than sharp shards, significantly reducing the risk of injury. This safety feature is particularly important in environments where glass breakage could pose a danger to people, such as homes and commercial buildings.

Moreover, tempered glass can withstand high thermal stress, making it suitable for areas exposed to extreme temperature changes, like glass doors leading to outdoor spaces or shower enclosures.

Conclusion

The process of creating tempered glass involves advanced techniques that transform ordinary glass into a robust material suitable for various applications. Its combination of strength, safety, and thermal resistance makes it an invaluable choice in design and architecture. As technology continues to advance, the production process will likely evolve to enhance efficiency and further improve the qualities of this remarkable material. Whether used in residential buildings, commercial structures, or decorative applications, tempered glass remains a testament to the innovation of modern engineering.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS