Dec . 13, 2024 08:31 Back to list

Techniques and Applications of Sandblasting Engraving for Creative Designs and Customization

The Art and Science of Sandblasting Engraving

Sandblasting engraving, also known as abrasive blasting or sand carving, is a technique widely used in the field of art and industrial applications to create intricate designs or etchings on a variety of surfaces. This method utilizes a high-pressure stream of abrasive particles, typically silica sand, to etch or cut into materials like glass, stone, metal, and even wood. The result is a stunning visual effect that not only adds aesthetic appeal but also durability to the engraved item.

The Process of Sandblasting Engraving

The sandblasting process begins with the preparation of the surface intended for engraving. This can include cleaning the surface to remove any dirt, oil, or residue that might interfere with the etching process. Once the surface is prepped, a design, whether it be a simple text or an intricate pattern, is either printed onto a stencil or directly transferred onto the surface. Stencils are particularly useful for more complex designs as they help achieve precision and ensure that the final product matches the intended artwork.

With the design in place, the sandblasting machine is set up. The machine consists of a pressure tank, an air compressor, and a nozzle through which the abrasive material is propelled. The type of abrasive material used can vary depending on the surface being engraved. For example, finer abrasives like aluminum oxide are often used for glass, while coarser materials like silica sand may be used for stone or metal surfaces.

Advantages of Sandblasting Engraving

One of the primary advantages of sandblasting engraving is its versatility. This method can be employed on various materials, making it suitable for creating personalized gifts, memorial plaques, business signage, or artistic sculptures. Furthermore, the depth and texture of the engraving can be modified by adjusting the pressure, the distance of the nozzle from the surface, and the angle at which the abrasive material is applied. This allows artists and craftsmen to exercise a high degree of creativity and customization in their work.

Another significant benefit of sandblasting is its durability. The engraved designs are resistant to fading, chipping, or peeling, making it an ideal choice for items exposed to the elements, such as outdoor signs or monuments. This longevity is particularly important for commemorative pieces or branding that needs to withstand the test of time.

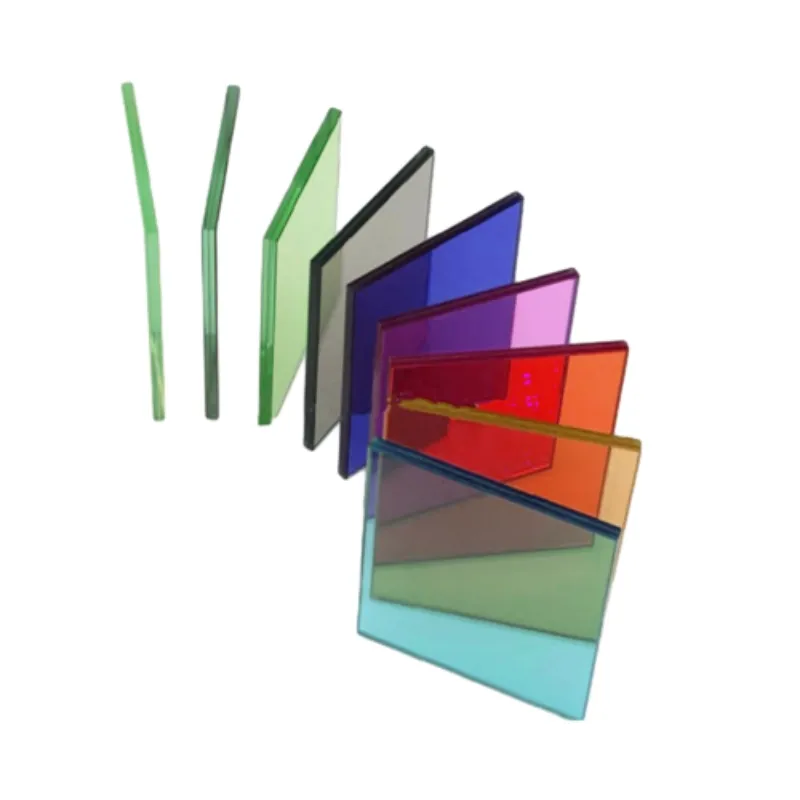

sandblasting engraving

Applications in Different Industries

Sandblasting engraving finds applications in various industries. In the architectural sector, it is often used to create decorative features on building facades or windows. Its ability to provide intricate designs makes it a popular choice for interior decorations as well, such as etched glass doors or partition walls.

In the realm of art, many artists leverage sandblasting to produce unique sculptures or glass art pieces. The ability to create detailed imagery and textures allows for a high level of artistic expression. Additionally, many artisans create custom engravings for gifts such as personalized awards, commemorative plaques, or decorative glassware.

In the commercial sector, businesses utilize sandblasting for branding purposes. Engraved logos or company names on glass doors or storefront windows serve as an eye-catching display that promotes the business while enhancing the overall aesthetics of the location.

Considerations and Safety

While sandblasting engraving is an effective and versatile technique, it requires careful handling due to the potential hazards associated with the process. Adequate safety measures must be followed, including wearing protective gear such as masks, goggles, and gloves to prevent inhalation of abrasive particles and protect against flying debris. Proper ventilation is also crucial, as fine dust can accumulate in enclosed spaces.

Conclusion

Sandblasting engraving is a remarkable fusion of art and engineering, allowing for both creativity and durability in creating designs on various materials. Whether employed for artistic endeavors, industrial applications, or personal gifts, this technique continues to grow in popularity due to its effectiveness and the stunning results it can achieve. As technology advances, new methods and materials continue to emerge, ensuring that sandblasting engraving remains a relevant and valuable tool in numerous fields for years to come.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS