Nov . 05, 2024 00:03 Back to list

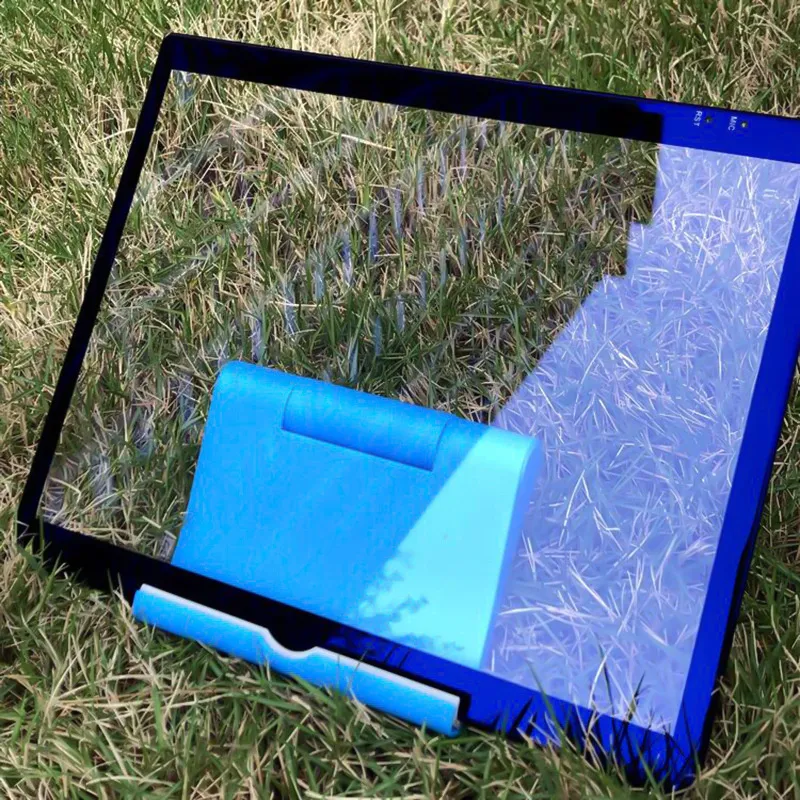

sandblasting engraving

The Art and Science of Sandblasting Engraving

Sandblasting engraving, also known as abrasive blasting or sandblasting etching, is a fascinating technique that combines artistry with precision. This method utilizes high-pressure air to propel abrasive materials—such as sand, glass beads, or other particulates—against a surface to create detailed engravings. While it may seem straightforward, the intricacies involved in sandblasting engraving reveal a craft that has captivated artists and artisans for centuries.

History of Sandblasting

The origins of sandblasting can be traced back to the late 19th century when it was first used for cleaning and surface preparation. However, it quickly evolved into an artistic medium. Early craftsmen discovered that the abrasive action could be harnessed to engrave intricate designs onto various materials, from glass to stone, metal, and beyond. This technique gained popularity due to its efficiency and ability to produce fine details, which were often difficult to achieve through traditional engraving methods.

The Process

At its core, the sandblasting engraving process is relatively straightforward but requires skill and the right equipment. Here’s an overview of the steps involved

1. Design Creation The first step is to create a design that will be engraved. This can be done using specialized software that allows artists to draw intricate patterns or logos. The design is then typically printed onto a stencil.

2. Surface Preparation The material to be engraved—be it glass, wood, or metal—must be prepared. This may involve cleaning the surface to remove any contaminants that could affect the engraving process.

3. Masking A mask or stencil is applied to the surface to protect areas that should not be engraved. This ensures that the design remains crisp and clear.

4. Sandblasting With the material prepared and masked, the actual sandblasting begins. An air compressor is used to propel abrasive particles towards the surface at high speed. The pressure can be adjusted based on the type of material and the desired intensity of the engraving. As the abrasive hits the surface, it removes material and creates the design.

sandblasting engraving

5. Finishing Touches After the sandblasting is complete, the surface often needs to be cleaned and finished. This could involve polishing or additional coatings, depending on the desired final appearance.

Applications of Sandblasting Engraving

The versatility of sandblasting engraving is one of its most appealing qualities. This technique is widely used across various industries, including

- Art and Decor Artists use sandblasting to create stunning visual designs on glassware, vases, mirrors, and plaques. - Automotive Customized glass etching for vehicles, including windshields and windows, has become increasingly popular among enthusiasts. - Memorials and Monuments Sandblasting is often employed to engrave names, dates, and personal messages on tombstones and memorial plaques, offering a lasting tribute. - Industrial Applications Beyond artistry, sandblasting is significant for surface preparation in manufacturing, cleaning molds, and removing coatings from machinery.

Advantages and Considerations

One of the primary advantages of sandblasting engraving is its efficiency. It can cover large areas quickly while still producing intricate details. Moreover, it allows for a high degree of customization, making it ideal for both personal projects and commercial applications.

However, there are considerations to keep in mind. The choice of abrasive medium can greatly influence the outcome; for instance, coarser materials may produce a rougher finish, while finer materials yield smoother results. Additionally, proper safety precautions must be taken to protect the operator from inhaling dust and particulates.

Conclusion

Sandblasting engraving is a blend of art, technology, and craftsmanship. Its ability to transform ordinary surfaces into works of art has made it a beloved technique among artists and craftsmen alike. As technology continues to evolve, the possibilities for sandblasting engraving are seemingly limitless, ensuring its place as a timeless method for creative expression. Whether for commercial purposes or personal projects, the allure of this craft remains ever strong, captivating both creators and spectators around the world.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS