Sep . 18, 2025 11:52 Back to list

Shott Clear Float, Extra Clear Float and Coated Float Glass

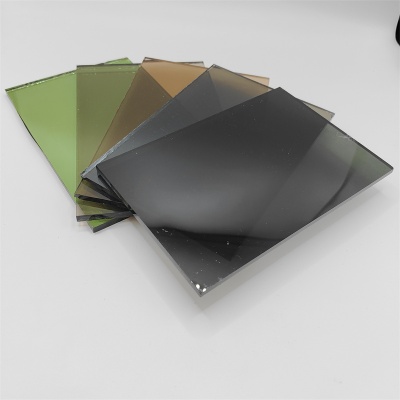

Glass is everywhere—on skyscraper facades, smartphone screens, home windows, and bathroom mirrors—but few realize how much innovation lies in a single sheet. For ShottGlass, glass is never just a “surface”; it’s a canvas for precision, functionality, and design. Their coated float glass is a perfect example: beyond its mirror-like sheen, it boosts energy efficiency, blocks UV rays, and adapts to diverse needs—from luxury hotel lobbies to high-tech electronics. Founded on the mission of delivering one-stop glass processing solutions for global OEM/ODM clients, ShottGlass has built its reputation on cutting-edge equipment and versatility. From crystal-clear clear float glass for everyday windows to ultra-transparent extra clear float glass for high-end displays, and high-performance coated float glass for energy-saving buildings, ShottGlass turns ordinary glass into extraordinary solutions. This is the story of how ShottGlass redefines glass—proving it’s more than a mirror, more than a window, but a core component of modern life.

ShottGlass’s Clear Float Glass Legacy: Precision in Every Sheet

ShottGlass’s journey began with a simple yet ambitious goal: to solve the pain points of global OEM/ODM clients who struggled to find a single partner for all their glass processing needs. Whether a client needed small, precision-cut glass for electronics or large, tempered panels for building facades, ShottGlass set out to deliver—backed by state-of-the-art equipment.

Today, the company’s workshop is a showcase of glass processing technology: a 45-meter-long tempering furnace for durable, heat-resistant glass; Intermac CNC work centers and cutting tables for pinpoint accuracy; double-edge grinding machines for smooth, safe edges; and specialized lines for acid etching, silk-screen printing, and mirror production. This full suite of equipment lets ShottGlass handle every step of glass processing in-house, from raw float glass to finished products like clear float glass windows, extra clear float glass displays, and coated float glass facades.

What makes ShottGlass stand out? Its commitment to “one-stop solutions.” A client designing a smart home might need coated float glass for energy-efficient windows, clear float glass for interior partitions, and extra clear float glass for touchscreen panels—ShottGlass delivers all, with consistent quality and on-time delivery. For over years, this versatility has made ShottGlass a trusted partner for clients across industries, proving that glass processing isn’t just about cutting and shaping—it’s about understanding and solving each client’s unique needs.

Clear Float Glass: ShottGlass’s Foundation of Versatility

Clear float glass is the backbone of ShottGlass’s product lineup—simple, reliable, and endlessly adaptable. It’s the starting point for most glass products, offering a smooth, transparent base that can be processed into everything from window panes to mirror substrates. ShottGlass’s clear float glass stands out for its consistency: thanks to advanced float glass production techniques, every sheet has uniform thickness, minimal defects, and high light transmittance—ideal for both functional and decorative use.

Below is a breakdown of ShottGlass’s clear float glass parameters and how they support diverse applications:

|

Parameter |

Specification |

Benefit for Clients |

|

Size (mm) |

1650x2200, 1830x2440, 1900x2440, 2140x3660, 2250x3660, 2250x3300, 2440x3660, 2440x3300, 2600x3300; custom sizes available |

Large standard sizes suit building projects (windows, facades); custom sizes fit niche needs (e.g., electronics, furniture). |

|

Thickness (mm) |

1.3, 1.6, 2.0, 2.5, 2.8, 3.2, 3.5, 3.8, 4, 4.5, 4.8, 5, 6, 8, 10, 12, 15, 19 |

Thin 1.3-3.8mm glass for lightweight applications (phone screens, picture frames); thick 10-19mm glass for heavy-duty use (glass doors, tabletops). |

|

Main Processing |

Tempered, mirrored, laminated, silk-screen printed, frosted |

Tempering adds strength for safety glass; silk-screen printing enables custom patterns (e.g., decorative windows); laminating boosts security (shatter-resistant). |

ShottGlass’s clear float glass is more than a “basic” product—it’s a flexible foundation. For a residential builder, it becomes energy-efficient windows (after coating); for a furniture maker, it turns into sleek glass tabletops (after tempering); for a mirror manufacturer, it’s the base for bathroom mirrors (after silvering). This versatility is why clear float glass remains one of ShottGlass’s most popular offerings: it adapts to any vision, no matter how big or small.

Extra Clear Float Glass: ShottGlass’s Transparent Excellence

When clarity matters most—think high-end retail displays, museum showcases, or architectural glass walls—extra clear float glass is the gold standard. Unlike regular clear float glass, which has a slight green tint (caused by iron in raw materials), ShottGlass’s extra clear float glass has ultra-low iron content, delivering nearly colorless transparency. This makes it perfect for applications where true color reproduction and maximum light transmittance are critical.

ShottGlass leverages its advanced processing equipment to enhance extra clear float glass’s performance. For example, its Intermac CNC work centers can cut the glass into intricate shapes for luxury jewelry displays, while its tempering furnace strengthens it for use in glass staircases (a popular design trend in modern homes). The glass’s uniform thickness (from 1.3mm to 19mm) also makes it ideal for laminated applications—like glass floors—where multiple layers need to align perfectly.

One of the biggest advantages of ShottGlass’s extra clear float glass is its compatibility with other processes. Coating it with Low-E (low-emissivity) layers turns it into energy-saving glass for skyscrapers; silk-screen printing adds subtle logos for retail storefronts; acid etching creates a frosted finish for privacy glass in offices. For clients who refuse to compromise on clarity, extra clear float glass is more than a product—it’s a way to make designs shine, unobscured by tint or imperfection.

Coated Float Glass: ShottGlass’s Multi-Functional Marvel

Coated float glass is where ShottGlass’s innovation truly shines. By adding thin, specialized coatings to clear float glass or extra clear float glass, the company transforms ordinary glass into a high-performance material that does far more than reflect light. The most popular coating is Low-E, which blocks infrared and UV rays: in summer, it keeps heat out (reducing air conditioning costs); in winter, it traps heat in (lowering heating bills). Other coatings include anti-glare (for screens and display cases), anti-fingerprint (for touchscreens), and self-cleaning (for hard-to-reach building facades).

ShottGlass’s coated float glass benefits from its in-house coating lines, which ensure even, durable layers that don’t peel or fade over time. The glass’s wide size range (up to 2600x3300mm) makes it suitable for large-scale projects—like the facade of a shopping mall—while custom sizes fit smaller applications, such as smart refrigerator doors. The coating process also pairs seamlessly with other treatments: tempering the coated glass makes it safe for use in skylights (it shatters into small, harmless pieces if broken), while laminating it adds security for bank windows.

What makes coated float glass “more than a mirror”? It’s a solution to real-world problems. A hotel using ShottGlass’s Low-E coated float glass cuts its energy bills by 30%; a museum using anti-glare coated extra clear float glass lets visitors see art without reflections; a homeowner using self-cleaning coated glass spends less time washing windows. For ShottGlass, coated float glass is the embodiment of its mission: to turn glass into a tool that makes life easier, more efficient, and more beautiful.

FAQs: Clear, Extra Clear & Coated Float Glass

Clear float glass: Custom size available?

Yes! ShottGlass offers custom sizes for clear float glass beyond standard options, fitting niche needs like furniture or electronics.

Extra clear float glass: Tint-free?

Absolutely. Extra clear float glass has ultra-low iron, delivering nearly tint-free transparency for true color display.

Coated float glass: Energy-saving?

Yes. Low-E coated coated float glass blocks heat/UV, cutting home/business energy costs significantly.

Clear float glass: Can be tempered?

Yes. ShottGlass tempers clear float glass for strength, ideal for safety-critical uses like skylights.

Why choose ShottGlass for float glass?

Choose ShottGlass for one-stop processing, advanced equipment, and quality clear, extra clear, and coated float glass.

ShottGlass’s float glass products—clear, extra clear, and coated—are more than just glass. They’re the result of precision engineering, customer-centric design, and a belief that glass can do more. Whether it’s a clear float glass window letting in sunlight, an extra clear float glass display showcasing art, or a coated float glass facade saving energy, ShottGlass proves that glass is a versatile, powerful material. For global OEM/ODM clients, this means more than just a product—it means a partner who understands their vision and has the tools to bring it to life. In ShottGlass’s hands, glass is never just a mirror—it’s a solution, a canvas, and a promise of better things to come.

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS