Nov . 04, 2025 04:55 Back to list

Special Glass: Types, Precision Cutting, Factory Direct

Special Glass is a key solution in the manufacturing industry, specifically within Non metallic mineral products industry and Special glass manufacturing. This article explores how SHAHE SHOTT GLASS Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Special Glass Overview

- Benefits & Use Cases of Special Glass in Special glass manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Special Glass from SHAHE SHOTT GLASS Co., Ltd.

Special Glass Overview

Special Glass refers to engineered glass products designed to deliver higher performance than standard float glass—whether that’s superior strength, optical quality, curvature, thermal stability, or safety. In the Non metallic mineral products industry, and particularly within Special glass manufacturing, the category spans multiple special glass types, including tempered, heat-strengthened, laminated, low-iron, anti-reflective, chemically strengthened, borosilicate, and bent/curved formats. For B2B decision makers, these types of special glass enable safer façades, sleek retail fronts, premium appliances, precise instrumentation, and resilient transportation glazing.

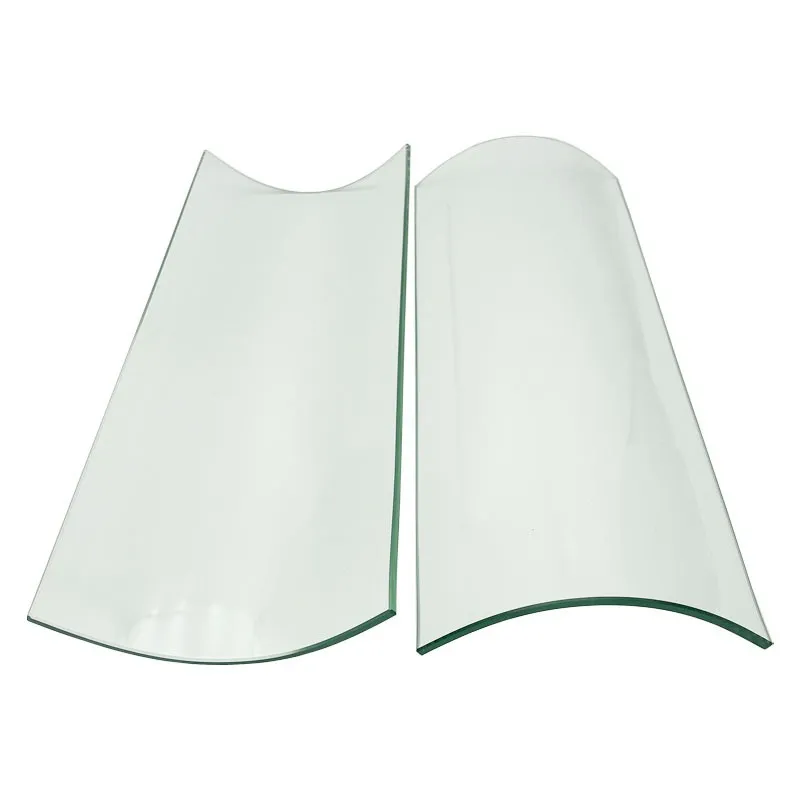

From a technical perspective, curved or bent Special Glass—such as the solutions offered by SHAHE SHOTT GLASS Co., Ltd.—is produced by heating glass to its softening point and shaping it over molds, followed by controlled cooling (tempering or heat strengthening) for safety performance. Typical options include thickness ranges commonly used in architecture and equipment, customizable bending radii, tight dimensional tolerances, and special glass cutting with CNC accuracy for holes, notches, and complex geometries. Edge finishing (arrised, flat-polished), printing, and coating options are also available to meet project-specific demands. As a reliable special glass factory partner, SHAHE SHOTT GLASS Co., Ltd. focuses on process control and repeatability to ensure consistent outcomes across batches.

Benefits & Use Cases of Special Glass in Special glass manufacturing

In Special glass manufacturing, Special Glass delivers measurable value across sectors. Architectural projects leverage bent/curved panels for façades, canopies, balustrades, interior partitions, and feature walls—creating signature aesthetics while meeting safety standards. In transportation and industrial equipment, curved safety glass improves aerodynamics and operator visibility. Retail showcases, refrigeration doors, and high-end appliances benefit from low-iron clarity, anti-reflective coatings, and precision special glass cutting that enables tight fit-up and fast assembly on the line.

- Performance: Tempered/laminated configurations for impact resistance and fail-safe behavior.

- Design freedom: Custom bending radii, multiple types of special glass, and digital printing for branding or privacy.

- Precision: CNC edgework and hole positioning for hardware alignment and reduced on-site rework.

- Quality consistency: Optical clarity and geometrical stability that scale from prototypes to large runs.

SHAHE SHOTT GLASS Co., Ltd. combines design assistance with manufacturability reviews, ensuring the chosen special glass types align with load, thermal, and tolerance requirements. The company’s bent and curved solutions, detailed on the product page, streamline procurement for OEMs and contractors alike by uniting forming, tempering, lamination, and finishing in one special glass factory workflow.

Cost, Maintenance & User Experience

For B2B buyers, total cost of ownership matters more than unit price. Special Glass typically reduces life-cycle costs by improving durability, limiting breakage, and maintaining visual quality longer, which lowers replacement and downtime expenses. With the correct specification—thickness, tempering method, curvature, and edgework—panels withstand operational loads, thermal cycling, and daily wear. Optional surface treatments can simplify cleaning and reduce maintenance frequency in high-traffic environments.

Customers in the Non metallic mineral products industry value predictable lead times, repeatable tolerances, and robust packaging that minimizes transit losses. Feedback from integrators and contractors frequently highlights the ROI of accurate special glass cutting and consistent curvature: faster installations, fewer site adjustments, and better fit with hardware systems. By engineering for manufacturability upfront, SHAHE SHOTT GLASS Co., Ltd. helps teams avoid hidden costs—shortening commissioning schedules and improving user experience through reliable optics, safety performance, and long-term stability.

Sustainability & Market Trends in manufacturing

Sustainability is reshaping Special glass manufacturing. Project teams increasingly seek materials that support energy-efficient envelopes, daylighting strategies, and longer service life. This encourages the use of low-iron glass for clarity, selective coatings for solar control, and durable laminations to extend replacement cycles. Regulations and green building frameworks continue to drive transparency around material performance and responsible sourcing, while designers use curved Special Glass to reduce framing, increase visibility, and enhance passive lighting.

SHAHE SHOTT GLASS Co., Ltd. aligns with these trends through process optimization, careful nesting during special glass cutting to reduce scrap, and a focus on long-lasting outcomes that lower the embodied impact over time. By supporting accurate specifications, advising on types of special glass for the application, and offering value-engineered alternatives, the team helps clients meet performance and sustainability goals without sacrificing design intent or delivery reliability.

Conclusion on Special Glass from SHAHE SHOTT GLASS Co., Ltd.

Special Glass empowers B2B teams across the manufacturing and Non metallic mineral products industry with safer structures, better optics, and signature design freedom—especially in curved and bent formats. As a trusted special glass factory partner, SHAHE SHOTT GLASS Co., Ltd. combines engineering guidance with consistent production quality, from special glass types selection to precision cutting and finishing. To discuss your next project, contact us: email: inquiry@chinamirrorglass.com — or visit our website: https://www.chinamirrorglass.com. Explore our bent/curved range here: https://www.chinamirrorglass.com/bent-curved-glass.html.

-

Types of Reflective Glass

NewsNov.17,2025

-

What Is Dichroic Glass?

NewsNov.17,2025

-

Smart LED mirrors can have touch controls

NewsNov.17,2025

-

Laminated glass improves energy efficiency

NewsNov.17,2025

-

Insulated glass enhances building comfort

NewsNov.17,2025

-

Acid etched glass offers elegant privacy

NewsNov.17,2025

Related PRODUCTS