Dec . 06, 2024 07:51 Back to list

special glass factory

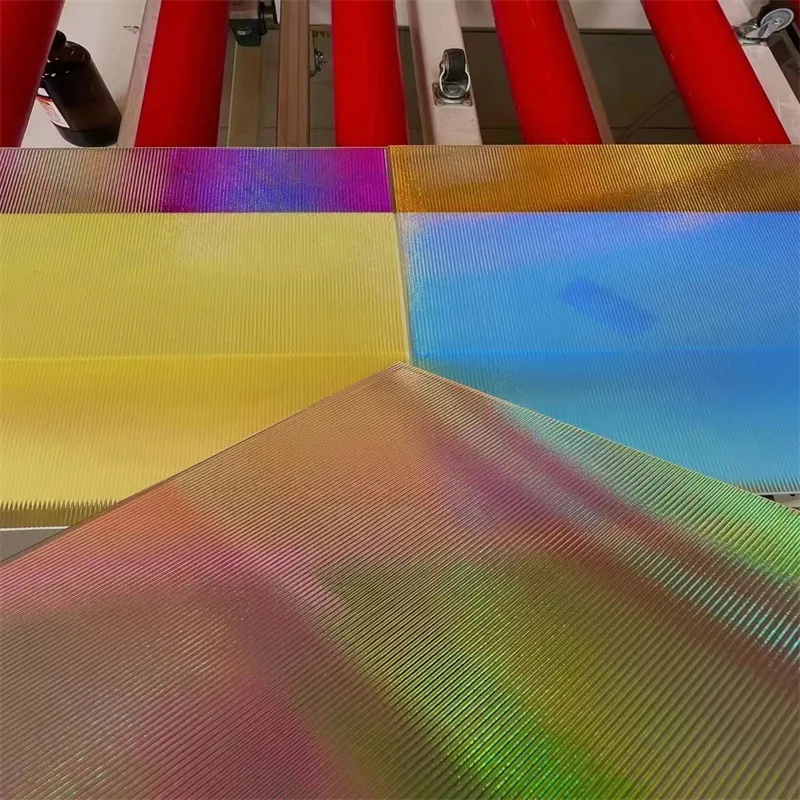

The Art and Craft of Special Glass Production

In the world of materials engineering, few substances are as versatile and captivating as glass. Among the myriad of applications, special glass has carved out a niche that caters to diverse industries ranging from telecommunications to aerospace, and from architecture to art. This article delves into the intricacies of special glass factories, exploring their production processes, innovative technologies, and the pivotal role they play in modern society.

Special glass factories are dedicated to producing glass products that possess unique properties suited for specific applications. Unlike traditional glass, which is primarily manufactured for everyday uses like windows or containers, special glass often exhibits enhanced features such as increased strength, thermal resistance, and electromagnetic shielding. The production of these materials involves a sophisticated blend of science, engineering, and artistry.

The Art and Craft of Special Glass Production

Once the raw materials are gathered, they undergo a melting process in high-temperature furnaces that can exceed 1,700 degrees Celsius. This phase is not just about melting; it is where the magic begins as the raw materials amalgamate into a homogenous molten glass. The furnace environment must be carefully controlled to prevent impurities that could compromise the glass quality. This is particularly crucial in the production of optical glass, which demands exceptional clarity and minimal distortion.

special glass factory

After the molten glass is produced, it is shaped and formed into the desired products. This stage of manufacturing can embrace a range of techniques, including blowing, pressing, casting, or even 3D printing. Each technique serves a unique purpose depending on the intended application. For instance, glass blowing creates intricate designs and forms that can enhance aesthetic appeal, while casting allows for mass production of complex shapes.

Post-formation, special glass often undergoes a series of processes tailored to enhance and refine its functional attributes. Annealing is one such process, where the glass is slowly cooled in a controlled environment to relieve internal stresses that could lead to breakage. Additionally, treatments such as tempering or laminating may be applied to increase strength and safety, particularly in applications like automotive windshields or architectural facades.

Another significant aspect of special glass production is the incorporation of advanced technologies. The rise of digital manufacturing and automation has revolutionized the industry, allowing for greater precision and efficiency in production processes. Factory robotics can handle delicate glass pieces with care, while computer numerical control (CNC) machines enable intricate cutting and shaping that would be challenging to achieve by hand. Furthermore, advancements in coatings and surface treatments have expanded the functionality of special glass, making it more resistant to scratches, UV radiation, and chemical corrosion.

As we look to the future, the role of special glass factories is set to expand even further. Innovations in nanotechnology and material science are paving the way for next-generation glass products that could respond to environmental conditions or even harness solar energy for electricity generation. The demand for lightweight, durable materials in aerospace and automotive industries will continue to drive research and development, ensuring that special glass remains at the forefront of technological advancement.

In conclusion, special glass factories represent a fusion of artistry and engineering excellence. Through meticulous processes and innovative technologies, they deliver exceptional materials that enhance the functionality and aesthetics of modern applications. Whether it’s in the form of high-performance windows that minimize energy consumption, or state-of-the-art glass fiber used in telecommunications, the impact of special glass is far-reaching. As industries evolve and new challenges arise, the special glass sector will undoubtedly continue to adapt and thrive, shedding light on the endless possibilities this remarkable material has to offer.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS