Nov . 21, 2024 13:08 Back to list

tempered glass manufacture

The Manufacturing Process of Tempered Glass Ensuring Strength and Safety

Tempered glass, also known as toughened glass, has become an essential material in various applications, ranging from architectural design to automotive manufacturing. Its strength and safety features make it an ideal choice for both residential and commercial uses. This article delves into the intricate manufacturing process of tempered glass, highlighting the steps that transform ordinary glass into a robust and resilient material.

Understanding Tempered Glass

To truly appreciate the manufacturing process, it’s important to understand what tempered glass is. Unlike standard glass, tempered glass undergoes a special thermal treatment that increases its strength. This process involves heating the glass to approximately 600 degrees Celsius (about 1,112 degrees Fahrenheit) and then rapidly cooling it. This rapid heating and cooling create compressive stresses on the surface, which enhance the glass's overall strength and resistance to thermal and mechanical stress.

The Manufacturing Process

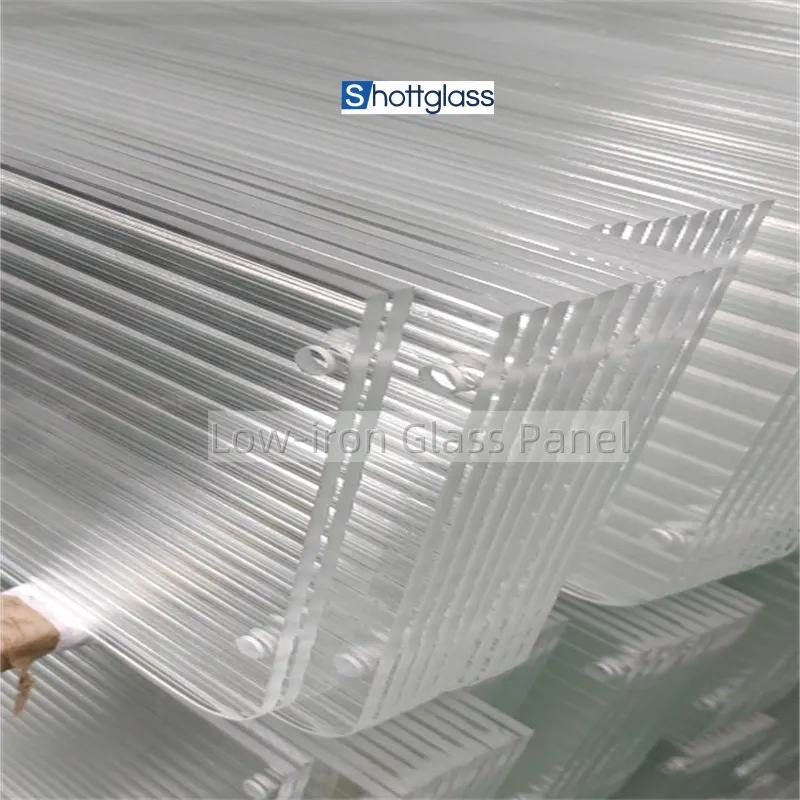

The journey to producing tempered glass begins with the selection of raw materials. High-quality silica sand, soda ash, and limestone are the primary components. These materials are mixed and melted at high temperatures, resulting in molten glass. This molten glass is then formed into flat sheets through a process called float glass production, where it is floated on molten tin to achieve a smooth surface.

Once the glass sheets are produced, they are carefully cut into the desired dimensions. Precision is crucial at this stage; any defects can compromise the safety and integrity of the final product. After cutting, the edges of the glass are polished to avoid chipping during the tempering process.

Tempering Process

tempered glass manufacture

The tempered glass manufacturing process consists of two main stages heating and cooling. In the heating phase, the glass sheets are gradually warmed in a tempering furnace to the specified temperature of around 600 degrees Celsius. This uniform heating is vital, as any uneven heating can lead to stress points that may cause failure.

Once the desired temperature is reached, the plates are rapidly cooled using high-velocity air jets. This cooling phase is known as quenching. The rapid temperature differential creates compressive stresses on the surface of the glass and tensile stresses internally. These stresses are what give tempered glass its strength. Notably, tempered glass is approximately five times stronger than standard glass of the same thickness.

Quality Control

After the tempering process, each sheet of glass undergoes rigorous quality control measures. It is inspected for defects such as bubbles, waves, or imperfections that could impact its performance. Advanced technology like optical imaging may be employed to detect subtle flaws. Only glass that meets strict standards goes on to be further processed or shipped to customers.

Applications of Tempered Glass

Tempered glass is favored for its safety features. When broken, it shatters into small, blunt pieces that are less likely to cause injury, making it an ideal choice for areas where safety is a concern, such as shower doors, glass facades, and car windows. Furthermore, its thermal resistance allows it to be used in building facades where temperature fluctuations are common.

In conclusion, the manufacturing process of tempered glass is a complex but rewarding endeavor. From raw material selection to the final quality checks, each step plays an integral role in producing a product that combines strength with safety. As a result, tempered glass has secured its place in modern architecture, automotive design, and countless other applications, continuing to be a critical material in our everyday lives. With ongoing advancements in technology, the potential for tempered glass applications seems only to expand, making it a fascinating field to watch in the years to come.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS