Nov . 17, 2024 01:31 Back to list

tin bath float glass

The Tin Bath Float Glass Process A Modern Marvel of Glass Manufacturing

The production of float glass has revolutionized the glass industry, particularly in architectural and automotive applications. One of the seminal innovations in this process is the tin bath, a pivotal component in the creation of high-quality float glass. This article delves into the tin bath float glass method, exploring its historical significance, technical intricacies, and the advantages that make it the preferred choice in many sectors.

Historical Context

The float glass process was developed in the mid-20th century by Sir Alastair Pilkington and was patented in 1952. This technique represented a breakthrough in glass manufacturing, allowing for the production of flat glass sheets with unparalleled smoothness and clarity. The introduction of the tin bath was a significant aspect of this process, providing a stable platform for molten glass to be uniformly flattened and cooled.

The Tin Bath Process Explained

In the float glass process, molten glass is poured into a bath of molten tin. This bath serves a dual purpose it creates a smooth surface on the glass while also supporting its weight as it cools and solidifies. The tin bath operates at a temperature of around 1,000 degrees Celsius, and the density of tin allows the lighter glass to float on its surface, which facilitates an even distribution across the width of the bath.

The glass is introduced at one end of the bath and gradually moves along its length. During this time, it spreads and flattens out, reaching thicknesses typically between 2 mm to 25 mm, depending on the desired end product. The overall process is continuous, allowing for efficient production rates and minimal waste.

Technical Advantages

tin bath float glass

One of the significant advantages of the tin bath float glass process is the high quality of the final product. The glass produced is remarkably flat and free from surface blemishes, making it ideal for applications where clarity and aesthetic quality are paramount, such as in architectural facades and high-end automotive windows. The controlled environment within the tin bath minimizes turbulence and contamination, resulting in superior optical properties.

Furthermore, the float glass produced via this method has excellent uniformity and consistency in thickness across large sheets. This quality is essential for applications that require precise fitting, such as in construction and specialized machinery.

Environmental and Economic Impacts

The tin bath process is not only efficient but also environmentally responsible. The continuous nature of the process reduces material waste significantly compared to traditional glassmaking methods. Additionally, modern float glass plants often incorporate advanced recycling techniques that allow for the reprocessing of glass cullet (scrap glass) back into the production cycle. This recycling reduces the energy required for melting raw materials and minimizes environmental impact.

From an economic standpoint, the float glass process is highly competitive. The scale of production that can be achieved with the tin bath method allows companies to meet high demand in various markets while maintaining cost-effectiveness. The ability to produce large sheets of glass efficiently has led to a widespread reduction in production costs and an increase in the availability of quality glass products.

Future Prospects

As technology continues to advance, the tin bath float glass process is likely to evolve further. Innovations in materials, automation, and energy efficiency will enhance the capabilities of glass manufacturing facilities. Additionally, the growing demand for energy-efficient and environmentally friendly building materials will drive innovations within the float glass segment.

In conclusion, the tin bath float glass process represents a remarkable achievement in the glass manufacturing industry. Through its unique method of production, it has set the standard for quality and efficiency, enabling the production of superior flat glass that meets the demands of contemporary architecture and automotive design. Its ongoing evolution promises not only to enhance glass quality and production efficiency but also to contribute to a more sustainable and economically viable future in glass manufacturing.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

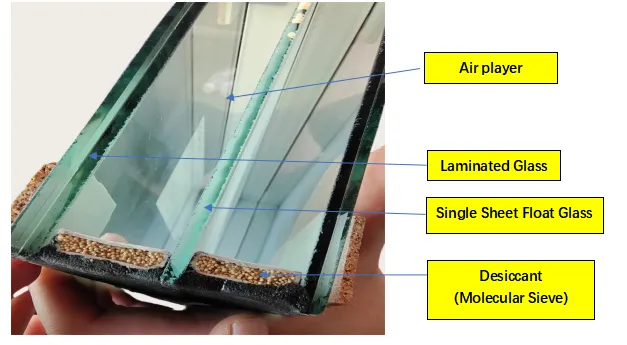

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS