Nov . 27, 2024 12:09 Back to list

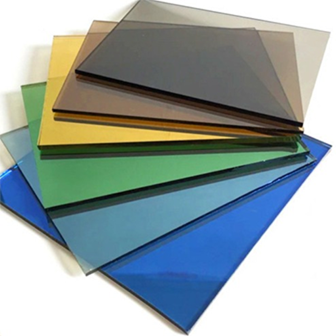

Tinted Glass Manufacturing Facility for Enhanced Privacy and Aesthetic Appeal

The Tinted Glass Factory Innovation in Modern Manufacturing

In today's world, tinted glass has become a crucial material used in various applications, from architecture to the automotive industry. The tinted glass factory plays an essential role in manufacturing this versatile product, using advanced techniques and innovative processes to meet the demands of modern consumers. This article explores the journey of tinted glass from raw materials to finished products, highlighting the technology and craftsmanship that define a successful tinted glass factory.

At the heart of tinted glass production is a combination of art and science. The process begins with selecting high-quality raw materials, primarily silica sand, soda ash, and limestone. These materials are carefully measured and mixed to create a homogeneous batch. The key to producing tinted glass lies in the incorporation of metallic oxides, such as iron, cobalt, and manganese, which impart the desired color and shade. The tinting process not only enhances the aesthetic appeal of the glass but also offers practical benefits, such as reducing glare and providing UV protection.

Once the batch is prepared, it is subjected to extreme heat in a furnace, reaching temperatures of around 1600 degrees Celsius. This process, known as melting, transforms the raw materials into molten glass. The molten glass is then shaped and formed into sheets through various techniques, including float glass production or pressing. Each method comes with its advantages, such as achieving different thicknesses and surface finishes, which can significantly affect the final product's quality and functionality.

After shaping, the newly formed tinted glass sheets undergo a rigorous cooling process, known as annealing. This step is crucial as it relieves the internal stresses within the glass, ensuring durability and preventing breakage. Depending on the factory's capabilities, additional processes such as polishing, laminating, or toughening may be applied to enhance the glass's properties further. These enhancements ensure that the tinted glass meets the specific requirements of diverse applications, including residential windows, office buildings, and vehicles.

tinted glass factory

A modern tinted glass factory is characterized by its use of advanced technology. Automated systems and computer-controlled machinery have revolutionized production efficiency, allowing for precise measurements and consistent quality. Labor-intensive tasks have been streamlined, enabling workers to focus on quality control and innovation. By adopting state-of-the-art techniques, factories can produce large volumes of tinted glass efficiently, reducing costs while maintaining high standards.

Sustainability is also a significant consideration in contemporary tinted glass manufacturing. Many factories are implementing eco-friendly practices, such as recycling glass waste and utilizing alternative energy sources. By minimizing their environmental impact, tinted glass factories are not only contributing to a sustainable future but are also appealing to an increasingly environmentally-conscious consumer base.

The market for tinted glass is expanding, driven by trends in energy efficiency and aesthetics. Architects and designers increasingly favor tinted glass for its ability to enhance building exteriors and regulate indoor temperatures. Additionally, automobile manufacturers are incorporating tinted windows to provide comfort, privacy, and UV protection to passengers. As demand grows, tinted glass factories are poised to innovate further and explore new methods and coatings that could improve performance and functionality.

In conclusion, the tinted glass factory represents a blend of tradition and modernity, where skilled craftsmanship coexists with cutting-edge technology. As consumers become more aware of tinted glass's benefits, the industry will continue to evolve, with manufacturers striving to meet new challenges while prioritizing quality, sustainability, and innovation. In this ever-evolving landscape, the tinted glass factory will undoubtedly play a pivotal role in shaping the future of this essential material.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS