Nov . 22, 2024 22:13 Back to list

toughened glass manufacturers

Toughened Glass Manufacturers An Overview

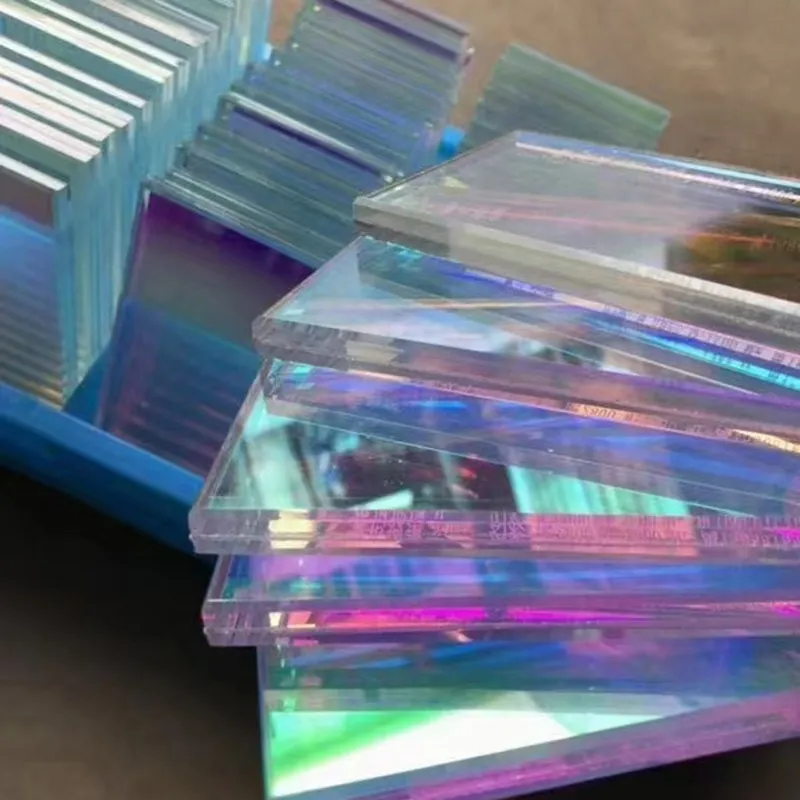

Toughened glass, also known as tempered glass, has transformed the way we think about safety and durability in construction and design. Its production involves a specialized process that renders the glass much stronger than regular glass, making it popular in residential, commercial, and automotive applications. The role of toughened glass manufacturers is pivotal in this context, as they are responsible for producing high-quality products that meet strict safety standards.

The Manufacturing Process

The production of toughened glass begins with standard float glass, which is cut to the desired dimensions. The glass is then subjected to a heating process that involves heating it to temperatures of around 620-650°C (about 1148-1202°F) before being rapidly cooled with jets of cold air. This process, known as tempering, creates residual compressive stresses on the surface of the glass while maintaining tensile stress in the center, resulting in a product that is significantly more resistant to impact and thermal shock.

Advanced technology plays a crucial role in this manufacturing process. Automated machinery and computer-controlled systems ensure that the glass is heated uniformly and cooled rapidly, which optimizes the strength and durability of the final product. It is also important for manufacturers to adhere to international safety standards and certifications, such as ASTM, EN, and ISO, to ensure that their products are suitable for a variety of applications.

Applications of Toughened Glass

Toughened glass is widely used in several industries. In the construction sector, it is employed in facades, windows, and balustrades due to its transparent yet strong nature. Its ability to shatter into small, blunt pieces upon breaking greatly reduces the risk of injury, making it an ideal choice for public spaces.

In the automotive industry, toughened glass is used for windows and sunroofs. The strength and and safety features of toughened glass are crucial for windshields, which need to withstand various stresses while ensuring passenger safety. Moreover, its thermal resistance allows it to cope with the rapid temperature changes often experienced by vehicles.

Other applications include shower enclosures, glass doors, and tabletop surfaces

. In furniture design, manufacturers use toughened glass for its aesthetic appeal and durability, allowing for sleek designs that do not compromise on safety.toughened glass manufacturers

Challenges Faced by Manufacturers

Despite the growing demand for toughened glass, manufacturers face several challenges. One of the main challenges is maintaining quality while scaling up production. As the market expands, manufacturers must find ways to increase output without sacrificing the consistency and quality of their product. This requires continual investment in technology and skilled labor.

Additionally, manufacturers must also navigate the volatility of raw material costs. Silica, soda ash, and other materials used to produce float glass fluctuate in price, which can impact production costs and profit margins. Manufacturers often need to develop strategic relationships with suppliers to mitigate these risks.

Moreover, toughened glass manufacturers are increasingly being called upon to innovate. With the rise of smart glass technologies that can change opacity or have integrated displays, manufacturers must adapt and expand their capabilities to incorporate these advanced features.

Future Trends in Toughened Glass Manufacturing

Looking ahead, the trend towards sustainability is likely to shape the future of toughened glass production. Manufacturers are exploring eco-friendly methods and materials to reduce their carbon footprint. The use of recycled glass is becoming more common, and processes that minimize energy consumption during production are being developed.

Moreover, advances in digital technology, such as automated production lines and AI-driven quality control systems, promise to streamline operations and improve product quality.

In conclusion, toughened glass manufacturers play a vital role in delivering safe, durable, and aesthetically pleasing glass products. As technology advances and consumer preferences evolve, these manufacturers will need to continually adapt and innovate to meet the demands of a changing marketplace. Whether through adopting sustainable practices or integrating smart technologies, the future of toughened glass appears bright, underscoring its importance across various industries.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS