Dec . 04, 2024 09:07 Back to list

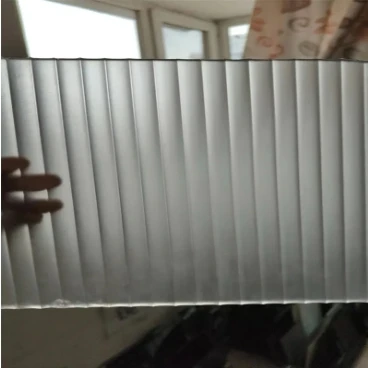

toughened glass manufacturers

The Evolution and Importance of Toughened Glass Manufacturers

Toughened glass, also known as tempered glass, has undergone a significant transformation in its manufacturing processes and applications over recent years. As a critical component in various industries, the role of toughened glass manufacturers has become increasingly vital. This article explores the evolution of toughened glass, its manufacturing process, the advantages it offers, and the market trends shaping the future of the industry.

Understanding Toughened Glass

Toughened glass is produced through a heating and rapid cooling process that enhances its strength compared to regular glass. During manufacturing, the glass is heated to over 600 degrees Celsius and then subjected to a quenching process, which cools the surface rapidly. This not only increases the glass's strength but also makes it more resistant to thermal shock. In the event of breakage, toughened glass fractures into small, blunt pieces, significantly reducing the risk of injury.

The Manufacturing Process

The manufacturing process of toughened glass involves several critical steps

1. Selection of Raw Materials The process begins with high-quality raw materials, primarily silica sand, soda ash, and limestone, which must meet strict industry standards.

2. Glass Melting These materials are melted together in a furnace at temperatures of around 1,300 to 1,600 degrees Celsius. The quality of the melt is crucial as impurities can weaken the final product.

3. Forming Once melted, the glass is shaped into panels or other desired forms using various techniques, including floating, pressing, or bending.

4. Annealing After forming, the glass undergoes an annealing process, which gradually reduces internal stresses within the glass to prepare it for toughening.

5. Toughening The key part of the manufacturing process involves heating the glass again and then rapidly cooling it. This step is what differentiates toughened glass from regular glass.

6. Quality Control Manufacturers conduct rigorous quality control tests to ensure that the glass meets safety standards and specifications before it is delivered to clients.

Advantages of Toughened Glass

toughened glass manufacturers

The advantages of toughened glass make it a preferred choice across various applications, including architecture, automotive, and household items

. Some of its key benefits include- Enhanced Strength Toughened glass is up to five times stronger than standard glass of the same thickness, making it an ideal choice for high-traffic areas and architectural designs.

- Safety Features Due to its breakage characteristics, toughened glass poses a lower risk of injury, making it suitable for public places like shopping malls and airports.

- Thermal Resistance Its ability to withstand sudden temperature changes makes it ideal for applications such as shower doors and oven doors.

- Aesthetic Appeal Toughened glass can be produced in various shapes, sizes, and finishes, which allows for more creative architectural designs and home interiors.

Market Trends

The toughened glass market is influenced by several trends and developments

1. Green Building Initiatives With an increasing focus on sustainability, many manufacturers are investing in eco-friendly processes and products, including energy-efficient glazing options.

2. Technological Advancements Innovations in manufacturing techniques have led to improved quality and precision, allowing manufacturers to offer bespoke solutions for clients.

3. Expanding Applications Beyond conventional uses, toughened glass is increasingly utilized in the electronics industry, for solar panels, and in innovative design applications.

4. Global Demand The rising construction and automotive sectors, particularly in emerging economies, are driving demand for toughened glass products globally.

Conclusion

Toughened glass manufacturers play a crucial role in ensuring the safety, durability, and aesthetic appeal of glass products used in modern life. As the industry continues to evolve with technological advancements and shifting market demands, the importance of these manufacturers will only grow. Their ability to innovate and adapt to changing trends will determine their success in meeting the needs of an ever-demanding market. The future of toughened glass lies in its versatility and the manufacturers' capacity to harness advancements in glass technology while adhering to safety and quality standards.

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS