Jan . 23, 2025 02:26 Back to list

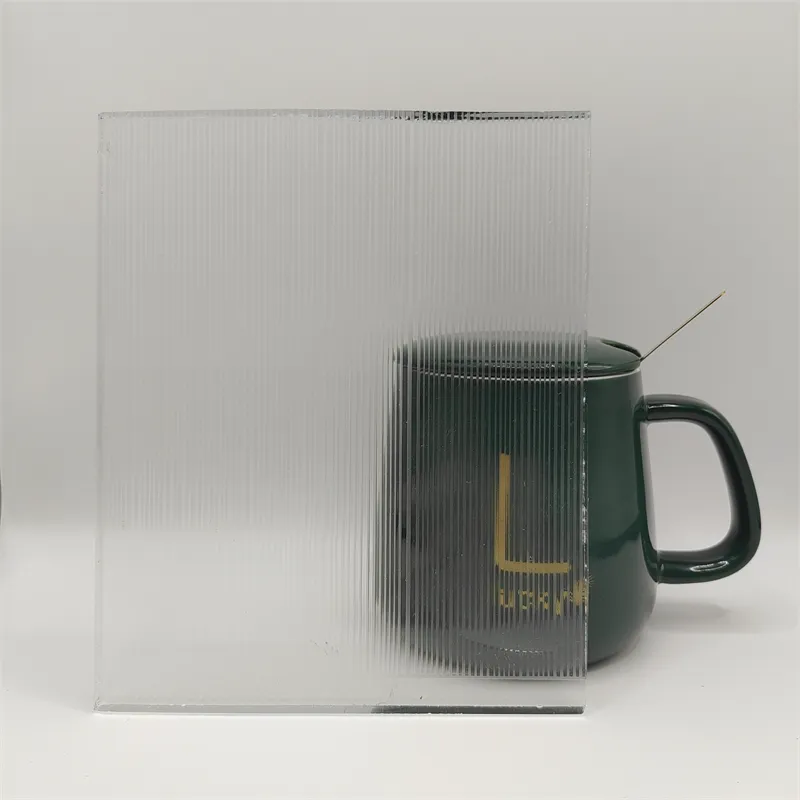

acid etched glass price

Glass etching is a fascinating technique that adds an artistic touch to glass surfaces, creating visually stunning designs. At the heart of this process is a particular acid, hydrofluoric acid (HF), renowned for its effectiveness in etching glass. Understanding the intricacies of how hydrofluoric acid is used in glass etching provides both professionals and enthusiasts with the know-how to perform it safely and effectively.

The etching process entails careful application of the hydrofluoric acid. This can be done using various methods, such as brushing, spraying, or immersion, depending on the complexity and size of the design. The contact time of the acid with the glass needs to be monitored closely, as longer exposure can lead to deeper etching, potentially compromising structural integrity. Precision in timing ensures that the etched patterns emerge clearly without over-etching. Once the desired effect is achieved, neutralizing the acid is critical. A rinsing solution, often containing a mild alkali like sodium bicarbonate, is applied to stop the etching process and safely neutralize any remaining acid. Afterward, the resist is carefully removed, revealing the etched design. A final rinse helps to remove all residues and enhances the glass surface's aesthetic. Expertise in glass etching with hydrofluoric acid comes not only from understanding its chemical properties but also from a keen eye for detail and artistic creativity. Practitioners must balance technical skill with creative vision to produce high-quality etched glass artworks. Ultimately, hydrofluoric acid remains unparalleled in glass etching, offering precision and versatility unmatched by other methods. For artisans and manufacturers, mastering this technique means unlocking new levels of craftsmanship and delivering unique, polished designs that capture attention and admiration. In summary, mastering glass etching with hydrofluoric acid requires a blend of chemical knowledge, safety awareness, and artistic sensitivity. By following stringent safety protocols, honing precise application techniques, and fostering creativity, one can achieve remarkable results in glass artistry.

The etching process entails careful application of the hydrofluoric acid. This can be done using various methods, such as brushing, spraying, or immersion, depending on the complexity and size of the design. The contact time of the acid with the glass needs to be monitored closely, as longer exposure can lead to deeper etching, potentially compromising structural integrity. Precision in timing ensures that the etched patterns emerge clearly without over-etching. Once the desired effect is achieved, neutralizing the acid is critical. A rinsing solution, often containing a mild alkali like sodium bicarbonate, is applied to stop the etching process and safely neutralize any remaining acid. Afterward, the resist is carefully removed, revealing the etched design. A final rinse helps to remove all residues and enhances the glass surface's aesthetic. Expertise in glass etching with hydrofluoric acid comes not only from understanding its chemical properties but also from a keen eye for detail and artistic creativity. Practitioners must balance technical skill with creative vision to produce high-quality etched glass artworks. Ultimately, hydrofluoric acid remains unparalleled in glass etching, offering precision and versatility unmatched by other methods. For artisans and manufacturers, mastering this technique means unlocking new levels of craftsmanship and delivering unique, polished designs that capture attention and admiration. In summary, mastering glass etching with hydrofluoric acid requires a blend of chemical knowledge, safety awareness, and artistic sensitivity. By following stringent safety protocols, honing precise application techniques, and fostering creativity, one can achieve remarkable results in glass artistry.

Next:

Latest news

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS