Feb . 04, 2025 02:59 Back to list

toughened glass for sale

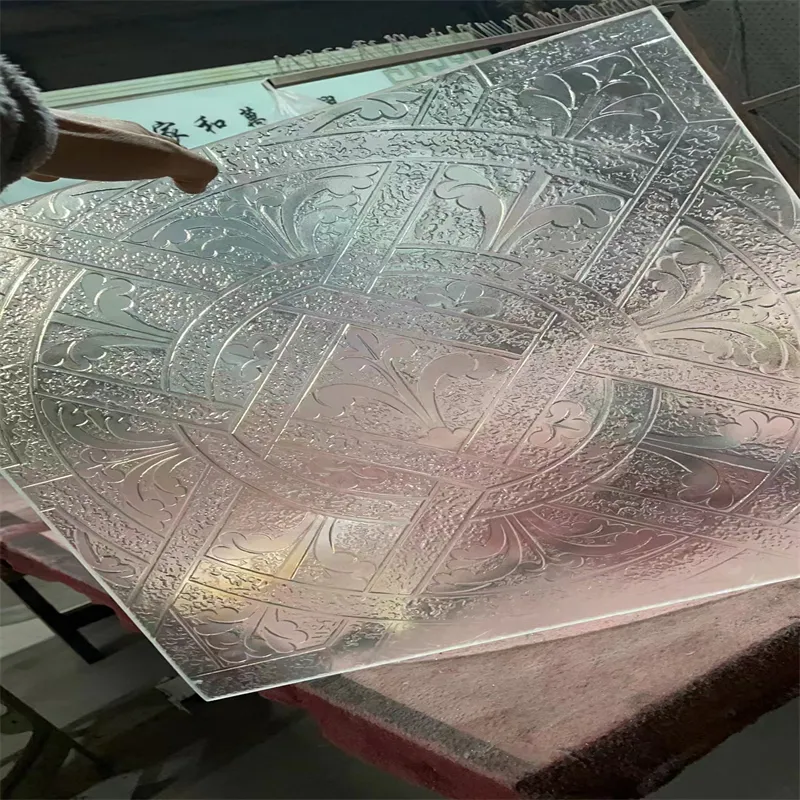

Toughened safety glass, also known as tempered glass, is a type of glass that is treated with thermal or chemical processes to increase its strength compared to normal glass. It is widely recognized for its improved safety features, which make it an ideal choice for a variety of applications, from automotive windows to architectural structures.

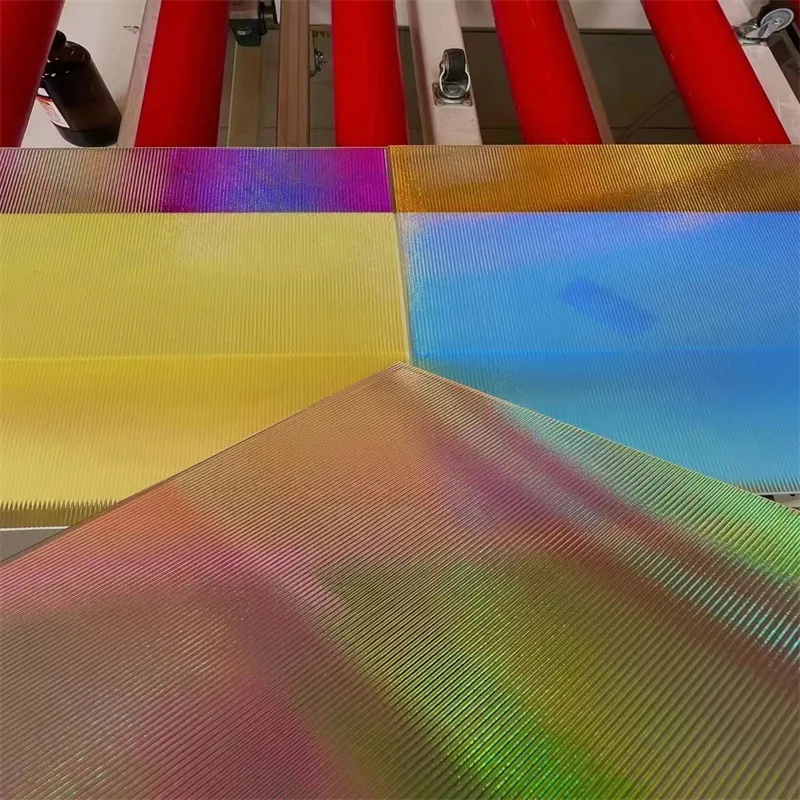

Technology-wise, toughened safety glass is making strides with innovations such as anti-reflective coatings, improving visibility and reducing glare, and hydrophobic coatings that enhance water repellence for improved vision in adverse weather conditions. As innovations continue, the potential applications of toughened safety glass are set to expand, meeting the needs of contemporary industries and environments. When it comes to residential applications, homeowners are increasingly choosing toughened safety glass for windows, doors, and even interior features like partitions and balustrades. The long-term durability of toughened glass makes it cost-effective; it requires minimal maintenance and withstands environmental challenges better than conventional glass. For consumers and businesses alike, understanding the unique attributes of toughened safety glass can inform purchasing decisions. Recognizing the balance it offers between strength, safety, and aesthetic appeal enables informed choices that ensure suitability for specific applications. Regulatory standards for toughened safety glass, such as those imposed by ANSI (American National Standards Institute) and CPSC (Consumer Product Safety Commission) in the U.S., establish benchmarks for safety, quality, and performance. Compliance with these standards guarantees that toughened safety glass performs reliably, providing protection and peace of mind to users. In conclusion, toughened safety glass represents a superior solution for many applications where safety, strength, and style are paramount. Its growing popularity across industries is a testament to its versatility and ability to meet the stringent demands of modern life. When choosing materials for construction, automotive, or home uses, the benefits of toughened safety glass make it a compelling choice, delivering a combination of resilience and safety that is unmatched by any other material.

Technology-wise, toughened safety glass is making strides with innovations such as anti-reflective coatings, improving visibility and reducing glare, and hydrophobic coatings that enhance water repellence for improved vision in adverse weather conditions. As innovations continue, the potential applications of toughened safety glass are set to expand, meeting the needs of contemporary industries and environments. When it comes to residential applications, homeowners are increasingly choosing toughened safety glass for windows, doors, and even interior features like partitions and balustrades. The long-term durability of toughened glass makes it cost-effective; it requires minimal maintenance and withstands environmental challenges better than conventional glass. For consumers and businesses alike, understanding the unique attributes of toughened safety glass can inform purchasing decisions. Recognizing the balance it offers between strength, safety, and aesthetic appeal enables informed choices that ensure suitability for specific applications. Regulatory standards for toughened safety glass, such as those imposed by ANSI (American National Standards Institute) and CPSC (Consumer Product Safety Commission) in the U.S., establish benchmarks for safety, quality, and performance. Compliance with these standards guarantees that toughened safety glass performs reliably, providing protection and peace of mind to users. In conclusion, toughened safety glass represents a superior solution for many applications where safety, strength, and style are paramount. Its growing popularity across industries is a testament to its versatility and ability to meet the stringent demands of modern life. When choosing materials for construction, automotive, or home uses, the benefits of toughened safety glass make it a compelling choice, delivering a combination of resilience and safety that is unmatched by any other material.

Next:

Latest news

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS