Jan . 13, 2025 11:34 Back to list

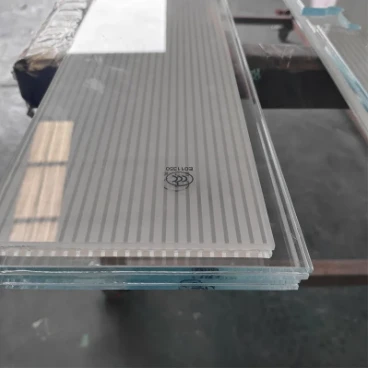

3mm clear float glass

3mm clear float glass stands as a fundamental material in a multitude of architectural and decorative applications. Praised for its high transparency and optical clarity, this type of glass is produced by floating molten glass on a bed of molten tin, creating a perfectly uniform thickness, hence ensuring its flawless finish.

Credibility in the production of 3mm clear float glass is paramount, with manufacturers adhering to rigorous quality standards and testing processes to ensure its safety and dependability. Leading producers routinely conduct impact resistance and load bearing tests to certify that each sheet meets the stringent demands of both residential and commercial use. Prospective buyers, whether they are architects, interior designers, or homeowners, should ensure the procurement of glass from reputable suppliers who provide verifiable product certifications and support eco-friendly production processes. Engaging with suppliers who offer advice, proper installation guidance, and after-sales support is crucial, furthering the trustworthy relationship necessary in a seamless design and construction process. In the realm of SEO and digital presence, creating content around the specifics of 3mm clear float glass, such as highlighting case studies of successful applications, customer testimonials, and detailed technical specifications, can significantly enhance online visibility and authority. As transparent as the material itself, this strategy helps establish a knowledge base that informs and educates stakeholders about the inherent benefits and applications of using 3mm clear float glass. In essence, 3mm clear float glass is not only a building material but a testament to modern engineering that combines traditional aesthetics with contemporary functionality. As industries continue to innovate, the adaptability and strategic use of this glass type promise a bright, efficient, and sustainable future.

Credibility in the production of 3mm clear float glass is paramount, with manufacturers adhering to rigorous quality standards and testing processes to ensure its safety and dependability. Leading producers routinely conduct impact resistance and load bearing tests to certify that each sheet meets the stringent demands of both residential and commercial use. Prospective buyers, whether they are architects, interior designers, or homeowners, should ensure the procurement of glass from reputable suppliers who provide verifiable product certifications and support eco-friendly production processes. Engaging with suppliers who offer advice, proper installation guidance, and after-sales support is crucial, furthering the trustworthy relationship necessary in a seamless design and construction process. In the realm of SEO and digital presence, creating content around the specifics of 3mm clear float glass, such as highlighting case studies of successful applications, customer testimonials, and detailed technical specifications, can significantly enhance online visibility and authority. As transparent as the material itself, this strategy helps establish a knowledge base that informs and educates stakeholders about the inherent benefits and applications of using 3mm clear float glass. In essence, 3mm clear float glass is not only a building material but a testament to modern engineering that combines traditional aesthetics with contemporary functionality. As industries continue to innovate, the adaptability and strategic use of this glass type promise a bright, efficient, and sustainable future.

Latest news

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS