Jan . 13, 2025 18:05 Back to list

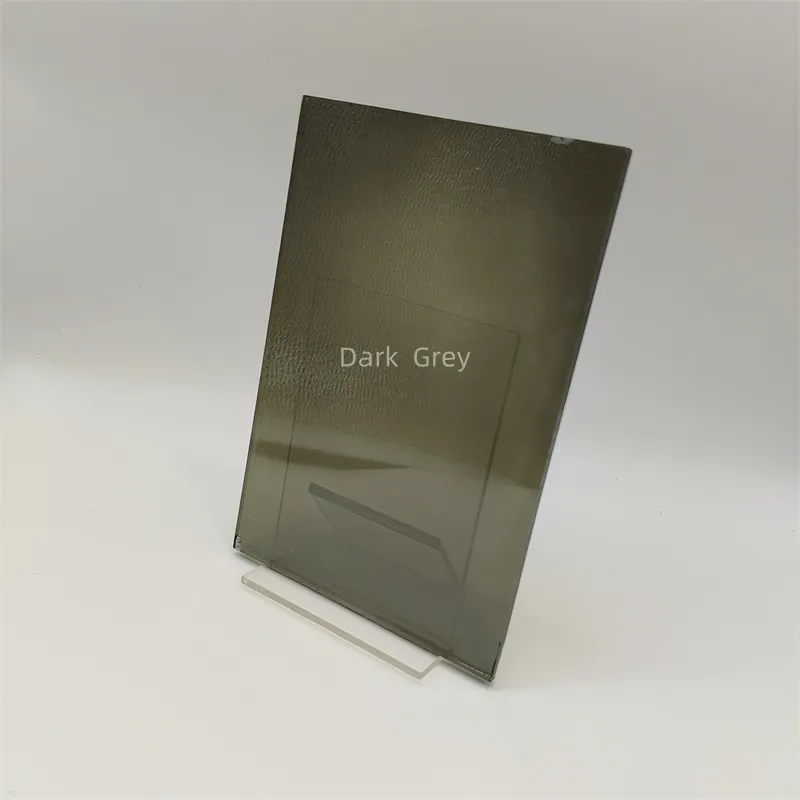

float flat glass

Flat glass has revolutionized the construction and design industries, underpinning modern architecture's sleek aesthetics. To truly appreciate its impact, one must delve into the intricate landscape of flat glass manufacturing, where innovation meets precision. As an industry insider, I’ve witnessed firsthand how advancements in manufacturing techniques have elevated not only product quality but also sustainable practices.

Trustworthiness is further reinforced by transparency and after-sales support. Reputable flat glass manufacturers tender comprehensive warranties, emphasizing the longevity and durability of their products. They provide detailed product specifications and performance data, instilling confidence in end-users. Additionally, their commitment to research and development frequently involves collaboration with scientific communities, enabling them to stay at the forefront of technological advancements and to address emerging market needs proactively. From a sustainability standpoint, pioneering companies in the flat glass sector are making great strides. The shift towards eco-friendly manufacturing processes is changing the landscape. Many manufacturers are reducing their carbon footprint through energy-efficient production techniques and investing in recycling programs. Utilizing up-to-date technologies like electric melting systems and employing recycled glass as a major component in production markedly reduces energy consumption and waste. In conclusion, flat glass manufacturers play a crucial role in shaping the built environment, armed with a blend of experience, cutting-edge expertise, authority, and trustworthiness. As the industry forges ahead, embracing innovation and sustainability, it remains a cornerstone of modern architectural advancements. The commitment to high standards and environmental responsibility ensures that these manufacturers continue to set benchmarks in quality and performance, maintaining their pivotal role in a rapidly evolving market.

Trustworthiness is further reinforced by transparency and after-sales support. Reputable flat glass manufacturers tender comprehensive warranties, emphasizing the longevity and durability of their products. They provide detailed product specifications and performance data, instilling confidence in end-users. Additionally, their commitment to research and development frequently involves collaboration with scientific communities, enabling them to stay at the forefront of technological advancements and to address emerging market needs proactively. From a sustainability standpoint, pioneering companies in the flat glass sector are making great strides. The shift towards eco-friendly manufacturing processes is changing the landscape. Many manufacturers are reducing their carbon footprint through energy-efficient production techniques and investing in recycling programs. Utilizing up-to-date technologies like electric melting systems and employing recycled glass as a major component in production markedly reduces energy consumption and waste. In conclusion, flat glass manufacturers play a crucial role in shaping the built environment, armed with a blend of experience, cutting-edge expertise, authority, and trustworthiness. As the industry forges ahead, embracing innovation and sustainability, it remains a cornerstone of modern architectural advancements. The commitment to high standards and environmental responsibility ensures that these manufacturers continue to set benchmarks in quality and performance, maintaining their pivotal role in a rapidly evolving market.

Next:

Latest news

-

Safety and Style with Premium Laminated Glass Solutions

NewsJun.24,2025

-

Reinvents Security with Premium Wired Glass

NewsJun.24,2025

-

Premium Float Glass Line for Modern Architecture

NewsJun.24,2025

-

Low Emissivity Glass for Energy-Efficient Architecture

NewsJun.24,2025

-

High-Performance Insulated Glass Solutions for Modern Architecture

NewsJun.24,2025

-

Elevates Interior Style with Premium Silver Mirror

NewsJun.24,2025

Related PRODUCTS